Crimping-type IGBT module with independently-formed chip and manufacturing method thereof

A chip and chip structure technology, which is applied in the field of high-power crimping IGBT modules and their preparation, can solve the problems of crimping IGBT modules, such as easy contamination, poor mechanical strength, and fretting wear, and improve assembly efficiency and assembly efficiency. Uniformity, avoiding fretting wear, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

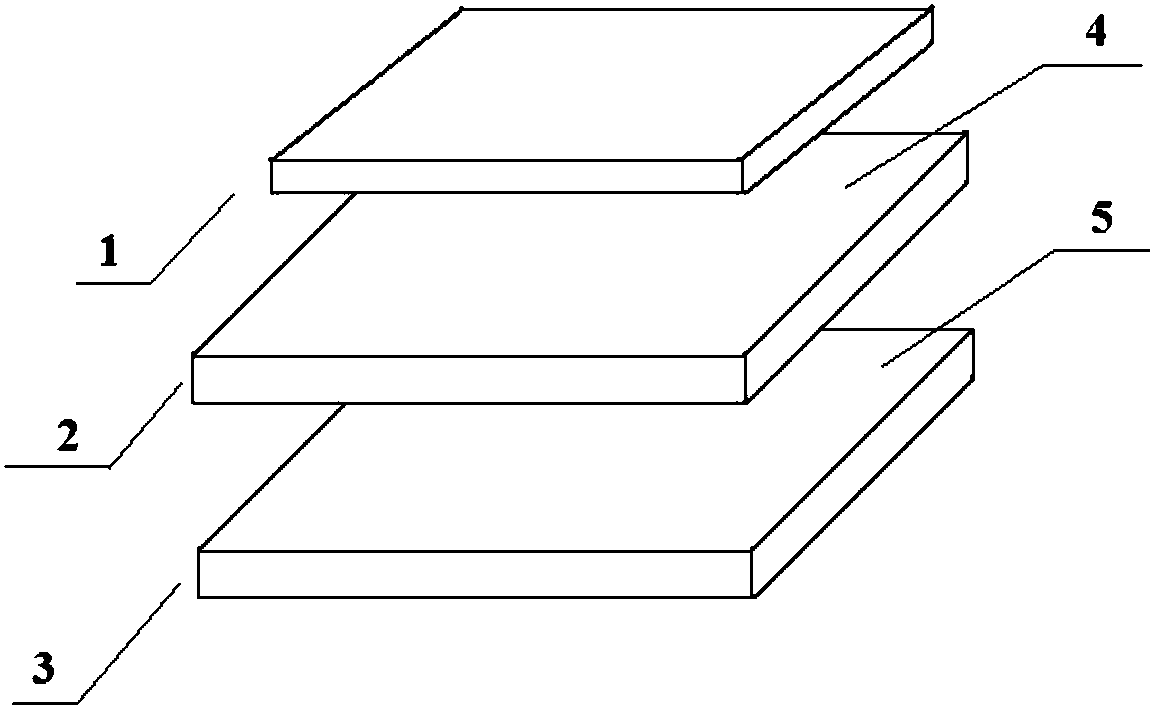

[0064] The crimping type IGBT module provided in this embodiment includes a cover plate, a chip assembly, a PCB board and a base in order from top to bottom. The chip assembly is composed of several chip units, each chip unit is composed of a chip structure and an insulating positioning member, and each chip structure is composed of a first conductive plane, a first sintering layer, a semiconductor chip, a second sintering layer, a second Composed of two conductive planes and an insulating shell, wherein the relative position of the chip sintered product composed of the first conductive plane, the first sintered layer, the semiconductor chip, the second sintered layer and the second conductive plane is as follows: figure 1 shown.

[0065] In this embodiment, the plastic frame is used as the insulating positioning member, and the surroundings of the chip structure are adhered to the top of the plastic frame. The top of the table is laminated; nano silver is used as the materia...

Embodiment 2

[0067] This embodiment provides a method for preparing the crimped IGBT module according to Embodiment 1 of the present invention, comprising the following steps:

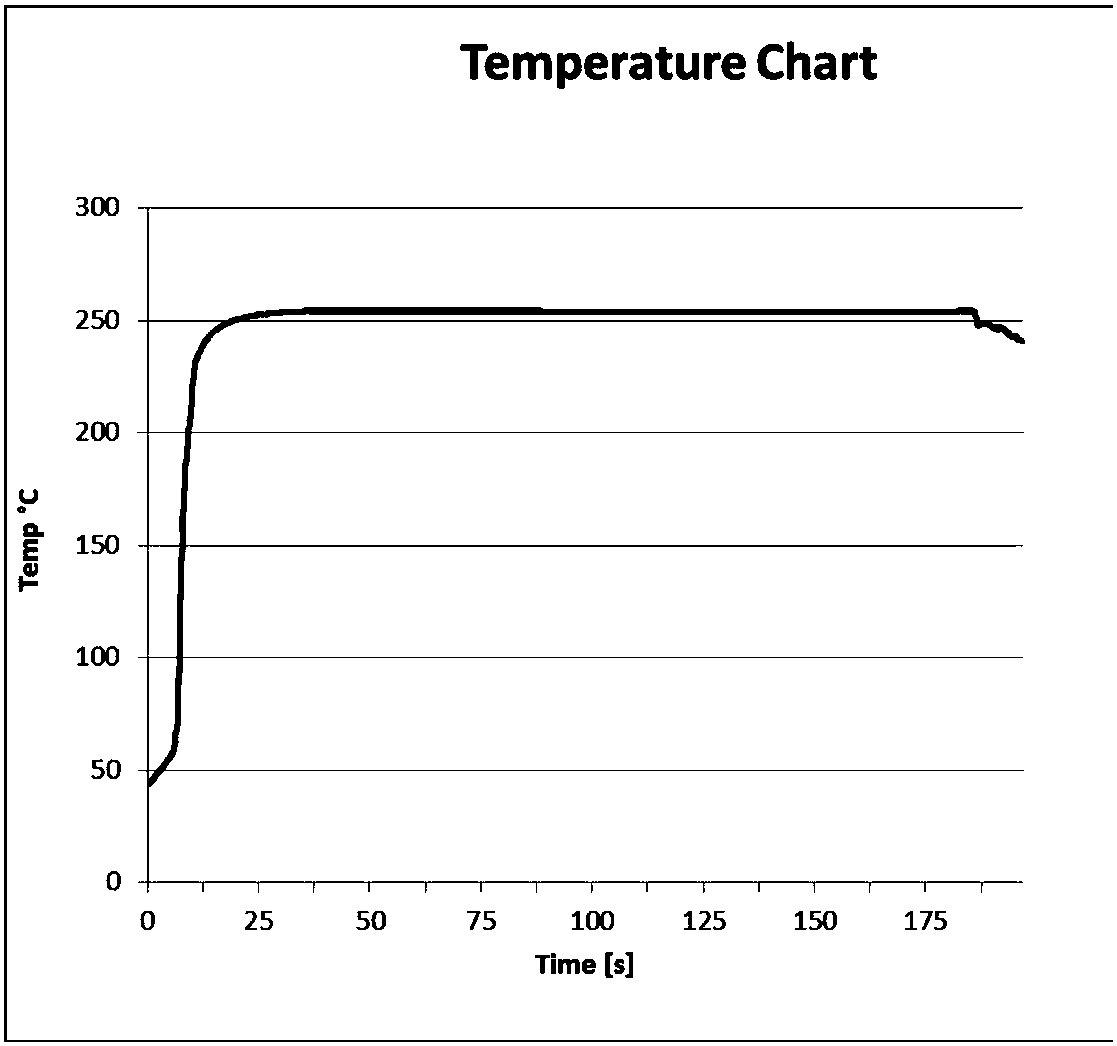

[0068] Preparation of chip sintered products: Get upper molybdenum sheet (bigger) and lower molybdenum sheet (lesser), and paste nano-silver film on one surface of upper and lower molybdenum sheet respectively, the thickness of described nano-silver film is 60 μ m, the nano-silver in film The content is 50wt%, and the upper and lower molybdenum sheets bonded with the nano-silver film are respectively subjected to pressure sintering at a sintering temperature of 110° C. and a pressure of 2 MPa to obtain a molybdenum sheet sintered with a nano-silver layer. Preferably, during the pressure sintering, the temperature is raised from room temperature to 110° C. at a rate of 5-10° C. / min, and then kept at a temperature of 15 minutes.

[0069] Vacuum ion sputtering is performed on the upper and lower surfaces of the semi...

Embodiment 3

[0078] The preparation method of the crimped IGBT module independently plastic-sealed by the chip product provided by this embodiment is roughly the same as that of Embodiment 2, and the difference is only in the following aspects:

[0079] The thickness of the nano-silver film used in this embodiment is 10 μm, the content of nano-silver in the film is 70wt%, the conditions of the first sintering are sintering temperature 140°C, pressurized pressure 6MPa, the conditions of the second sintering are sintering temperature 320°C, The pressurized pressure is 35MPa; preferably, when the first sintering and the second sintering are carried out, the temperature is raised from room temperature to the sintering temperature at a rate of 5-10°C / min, and then the first sintering is held for 10-15 minutes, and the second Keep warm for 20-60 minutes during sintering. During plastic sealing, this embodiment uses polyether ether ketone as the material of the plastic sealing mold.

[0080]The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com