Low-cost high-power electronic device packaging technology

A packaging process and technology for electronic devices, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of high price of gold-tin preforms, troublesome solder paste coating process, and high void rate of thermal interface solder layers. problems, to achieve the effect of reducing the void rate, reducing the process, and reducing the cost of gold plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

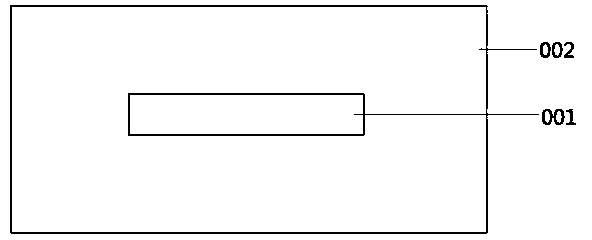

[0027] Such as figure 1 As shown, the chip 001 is pasted on the surface of the flange 002, using a gold-silicon eutectic soldering process or a gold-tin eutectic soldering process with a low void rate in the soldering layer.

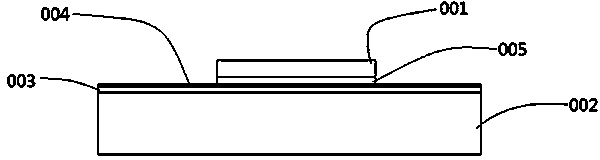

[0028] Such as figure 2 As shown, a thick gold layer or gold-tin layer 005 is prepared on the back of the chip 001, the thickness of the thick gold layer or gold-tin layer 005 is between 1um-6um, the nickel-plated layer 003 on the surface of the flange 002, the thickness of the nickel-plated layer 003 is Between 2um-15um, a thin gold layer 004 is plated on the nickel-plated layer 003, and the thickness of the thin gold layer 004 is between 25nm-1um. When the flange temperature exceeds the melting point of gold-silicon alloy or gold-tin alloy, a gold-silicon alloy or gold-tin alloy is formed between the chip 001 and flange 002, and they are firmly welded together to achieve gold-silicon eutectic welding or gold-tin eutectic welding Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com