Circuit board manufacturing process

A circuit board manufacturing and circuit board technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit secondary processing, etc., can solve the problems of increasing the cost of gold plating on printed circuit boards, wasting gold salt materials, etc., to reduce the cost of gold plating, reduce effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

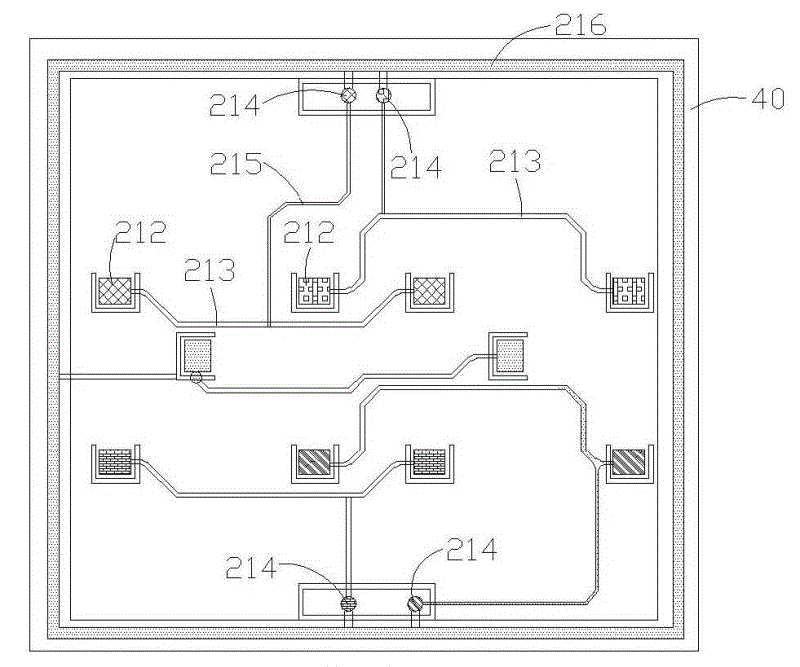

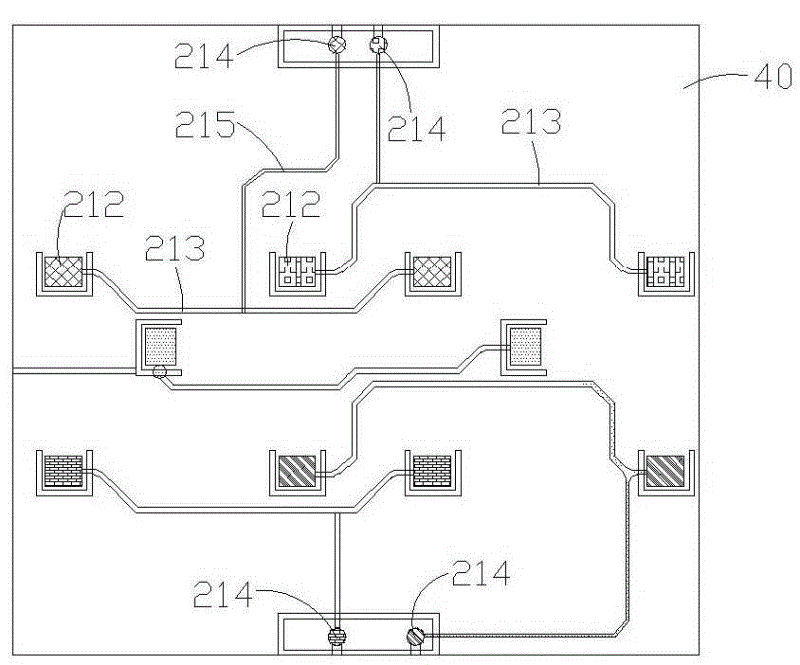

[0026] The circuit board manufacturing process of the present invention can be used to manufacture single-layer circuit board or multi-layer circuit board, take single-layer circuit board as example, as figure 1 As shown in the circuit board manufacturing flow chart of a preferred embodiment of manufacturing a single-layer circuit board according to the present invention, the circuit board manufacturing process of the present invention mainly includes the following steps.

[0027] a. Provide copper foil substrate; the copper foil substrate can be pre-cut to the size suitable for the factory process.

[0028] b. Duplicate a predetermined single-layer circuit pattern on the copper foil substrate; copy the drawn circuit pattern on the copper foil substrate by direct photoresist or indirect printing.

[0029] c. Remove the copper foil other than the circuit pattern of the copper foil substrate, so that a single-layer circuit layer composed of copper foil is formed on the copper fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com