Production method of valve workpiece

A production method and workpiece technology, applied in the field of parts processing, can solve problems such as difficult to meet market demand, lower valve body manufacturing efficiency, and affect product quality, and achieve the effects of improving overall aesthetics, reducing rework, and smoothing the outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

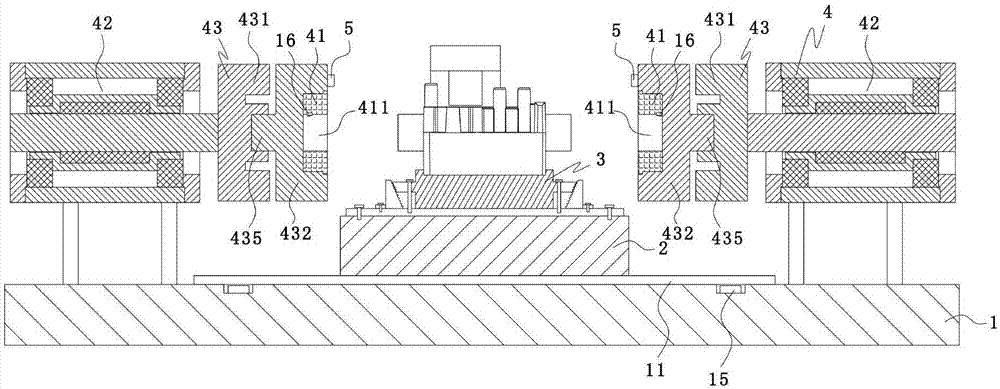

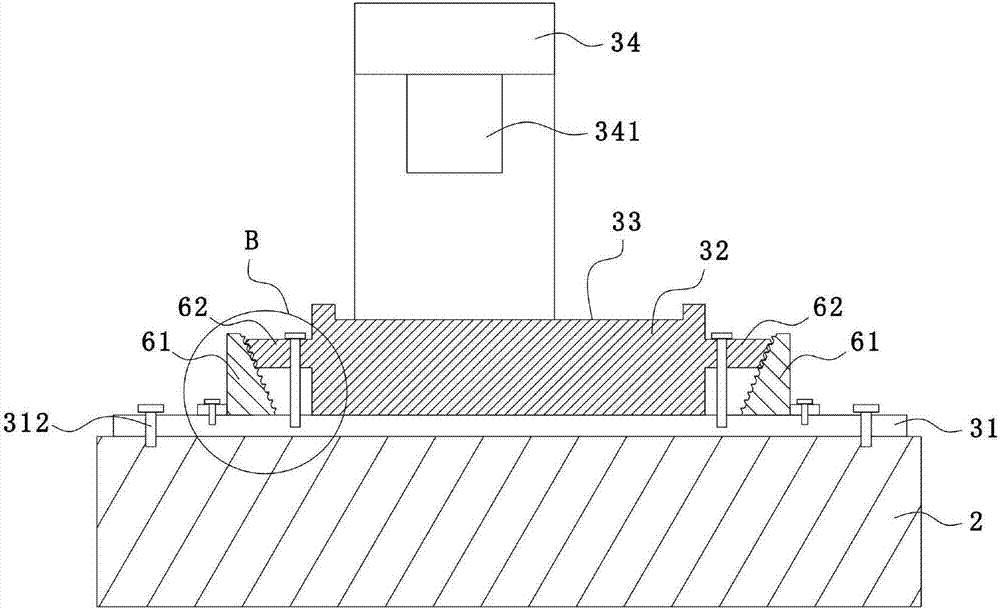

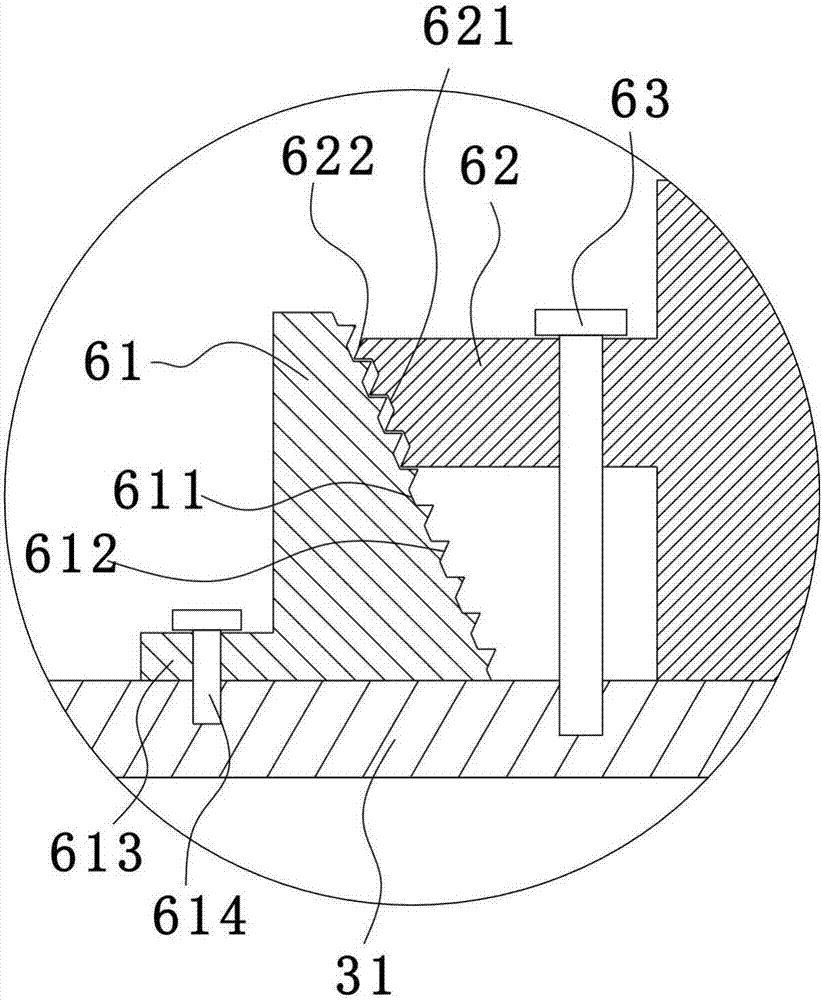

[0033] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0034]A method for producing a valve workpiece, comprising the following steps: (1) casting molding: injecting molten aluminum at high temperature into a workpiece mold, and performing die-casting molding by a die-casting machine, the die-casting temperature being controlled at 650-690°C, The filling time is 1-2 seconds, the filling pressure is 10-15Mpa, and the workpiece blank is obtained after the aluminum liquid is cooled; (2) Material handle removal: the material handle of the workpiece blank in step (1) is processed by cutting equipment Excision; (3) workpiece deburring; using deburring equipment to remove the burrs on the outer surface of the workpiece and the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com