Anti-fouling device for air conditioner accessory cutting device

A technology for cutting devices and accessories, applied in maintenance and safety accessories, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as clean waste disposal, pollution of the working environment, mildew in waste boxes, etc., to reduce work Labor, cleanliness assurance, pollution prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

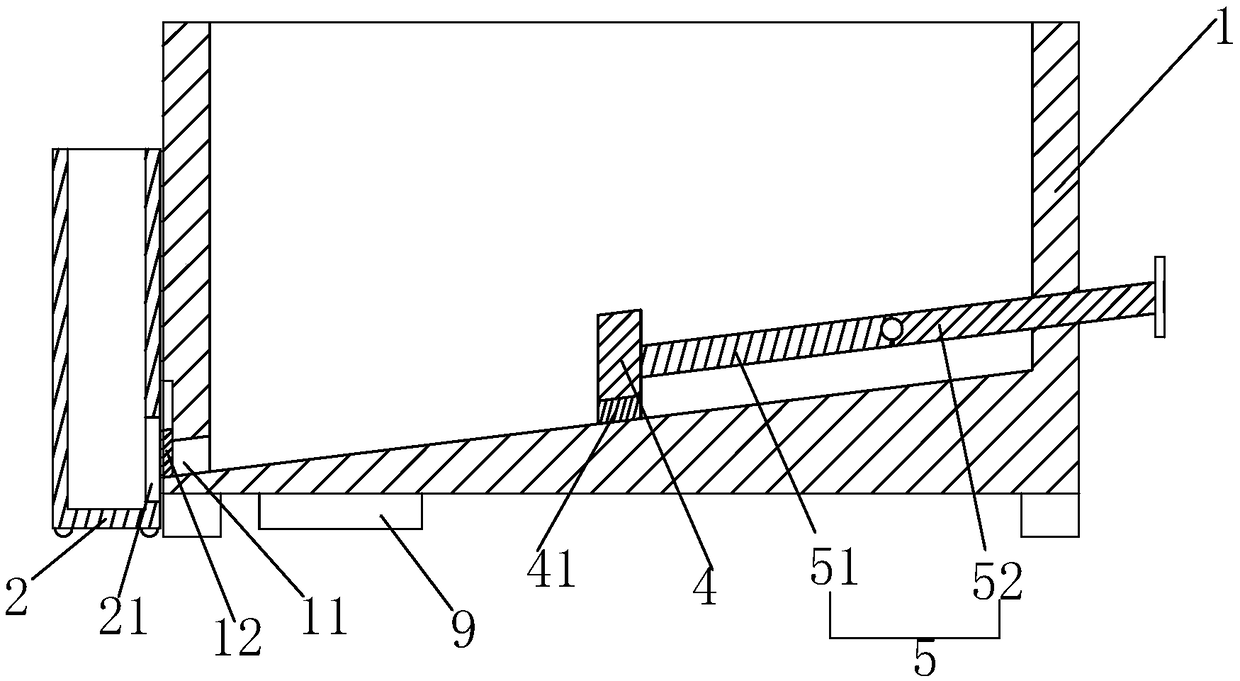

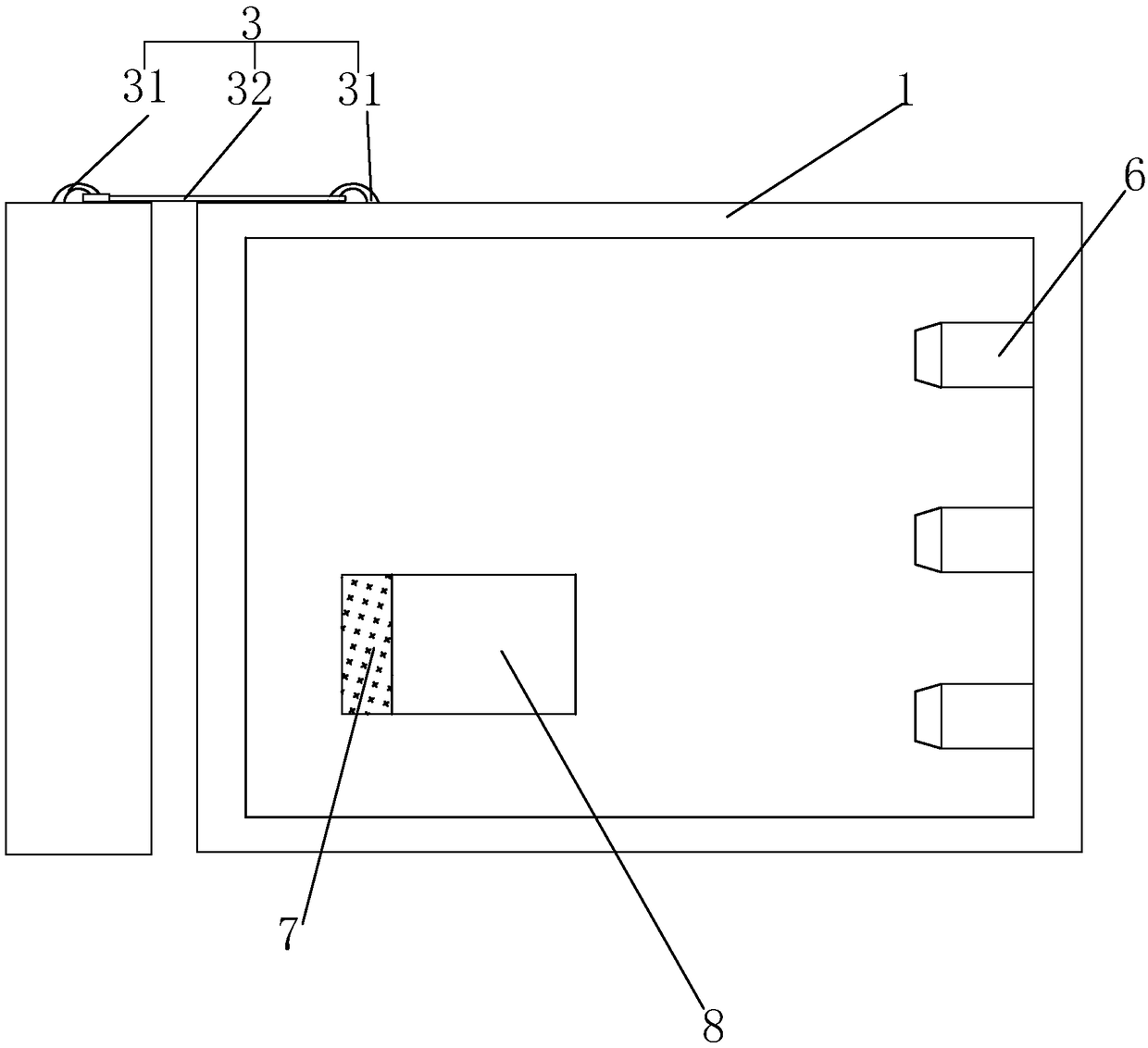

[0019] Embodiment 1: A kind of antifouling device used in the cutting device of air-conditioning accessories, such as figure 1 with 2 As shown, the waste bin 1 is included, the bottom of the waste bin 1 is inclined, and the side wall at the lowest end is provided with a discharge port 11, and the discharge port 11 is provided with a valve to realize the closure of the discharge port 11. Electric switch door 12, one side of described waste bin 1 is also provided with the carrier 2 that communicates with discharge port 11, and the feed port 21 of described carrier 2 is lower than discharge port 11, and the inside of described carrier 2 Garbage bags (not shown in the figure) are provided, and the transport vehicle 2 is connected to the waste bin 1 through the connection mechanism 3. Ring 31, a connecting hook 32 is sleeved on the fixed ring 31 positioned on the carrier 2, so that the connecting hook 32 is hooked on the fixed ring 31 positioned at the waste bin 1 so that the posi...

Embodiment 2

[0023] Embodiment 2: An antifouling device used in the cutting device of air-conditioning accessories, the difference from Embodiment 1 is that, as figure 2 As shown, at this time, a plurality of water pipes 6 toward the lower end are provided on the side wall of the waste bin 1 away from the discharge port 11, and the bottom of the waste bin 1 is provided with a pipe near the discharge port 11. The liquid storage box 9, the waste material box 1 is located directly above the liquid storage box 9 and is provided with a filter screen 7 communicating with the liquid storage box 9, and the filter screen 7 is slidingly provided with a switch plate overlapping with the filter screen 7 8. The upper surface of the switch plate 8 is flush with the inner bottom surface of the waste bin 1 .

[0024] After most of the waste in the waste box 1 is removed, clean water can be poured into the waste box 1 through the water pipe 6 to flush the waste box 1, and some small wastes are also remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com