Flat paper tube reeling machine

A flat roll paper and paper tube machine technology, applied in the field of paper tube production equipment, can solve the problems that the paper tube production process cannot be carried out normally, affect the quality of the paper tube, and have a greater impact, so as to reduce the amount of cutting and improve the quality of the paper tube , the effect of preventing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

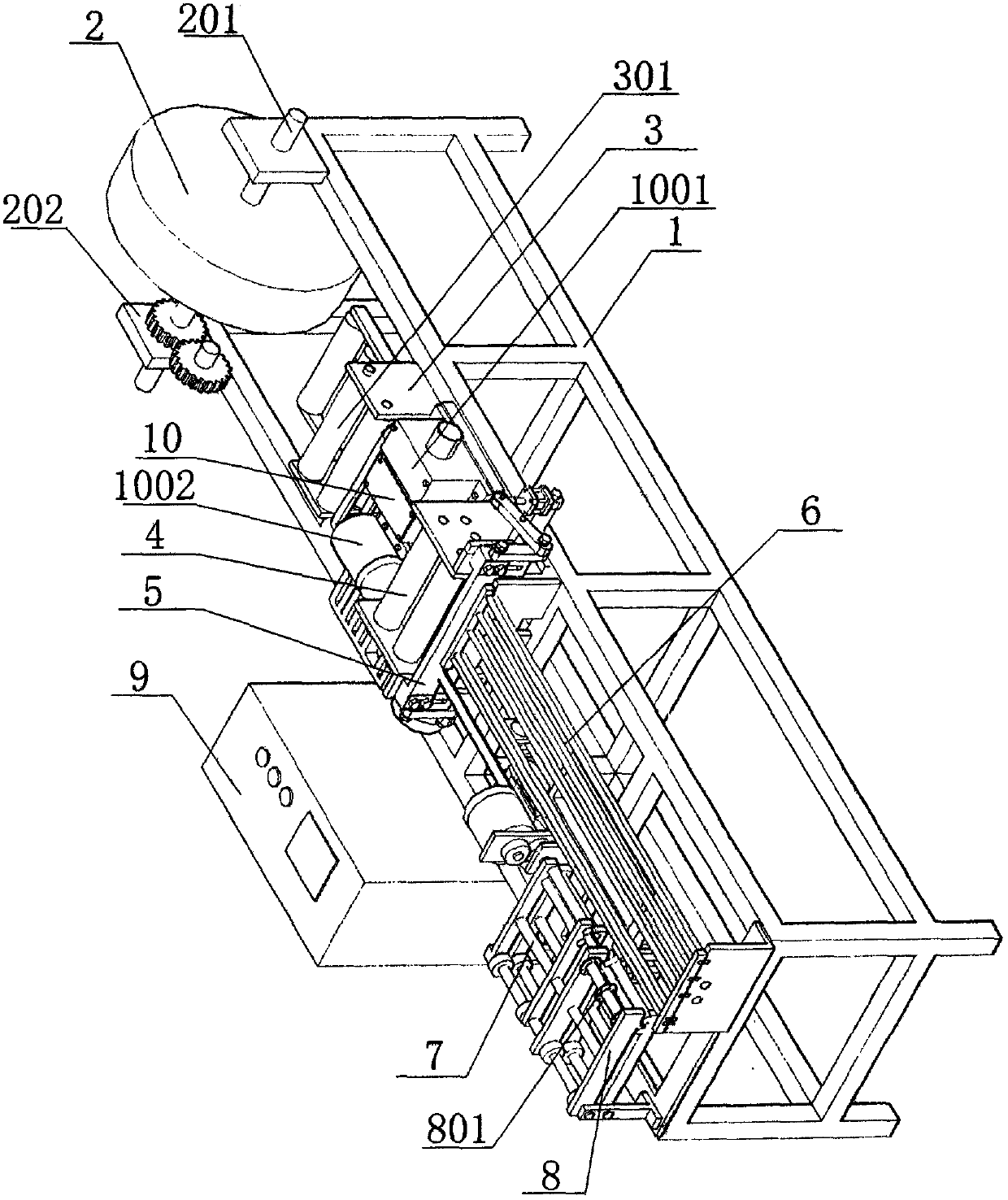

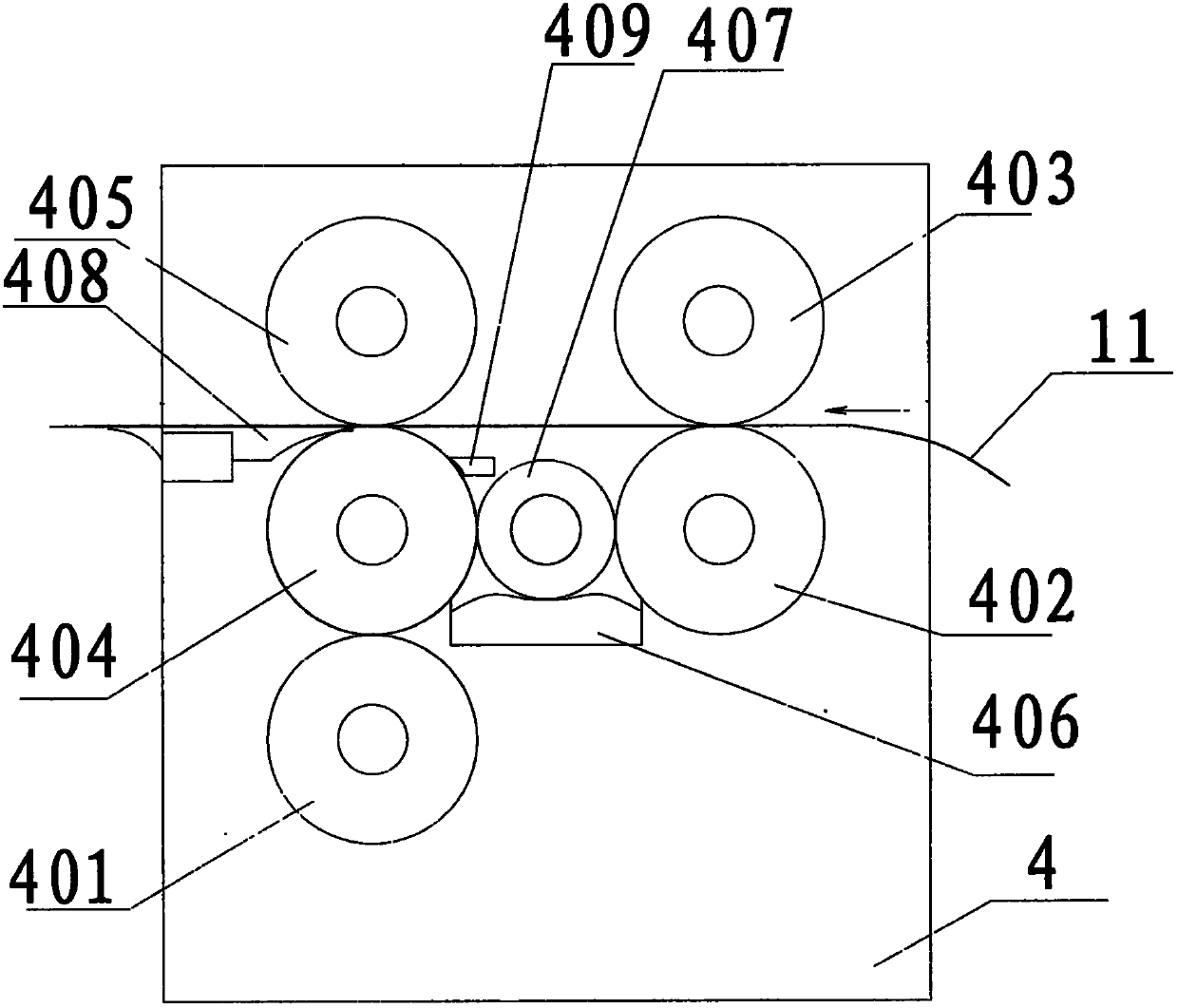

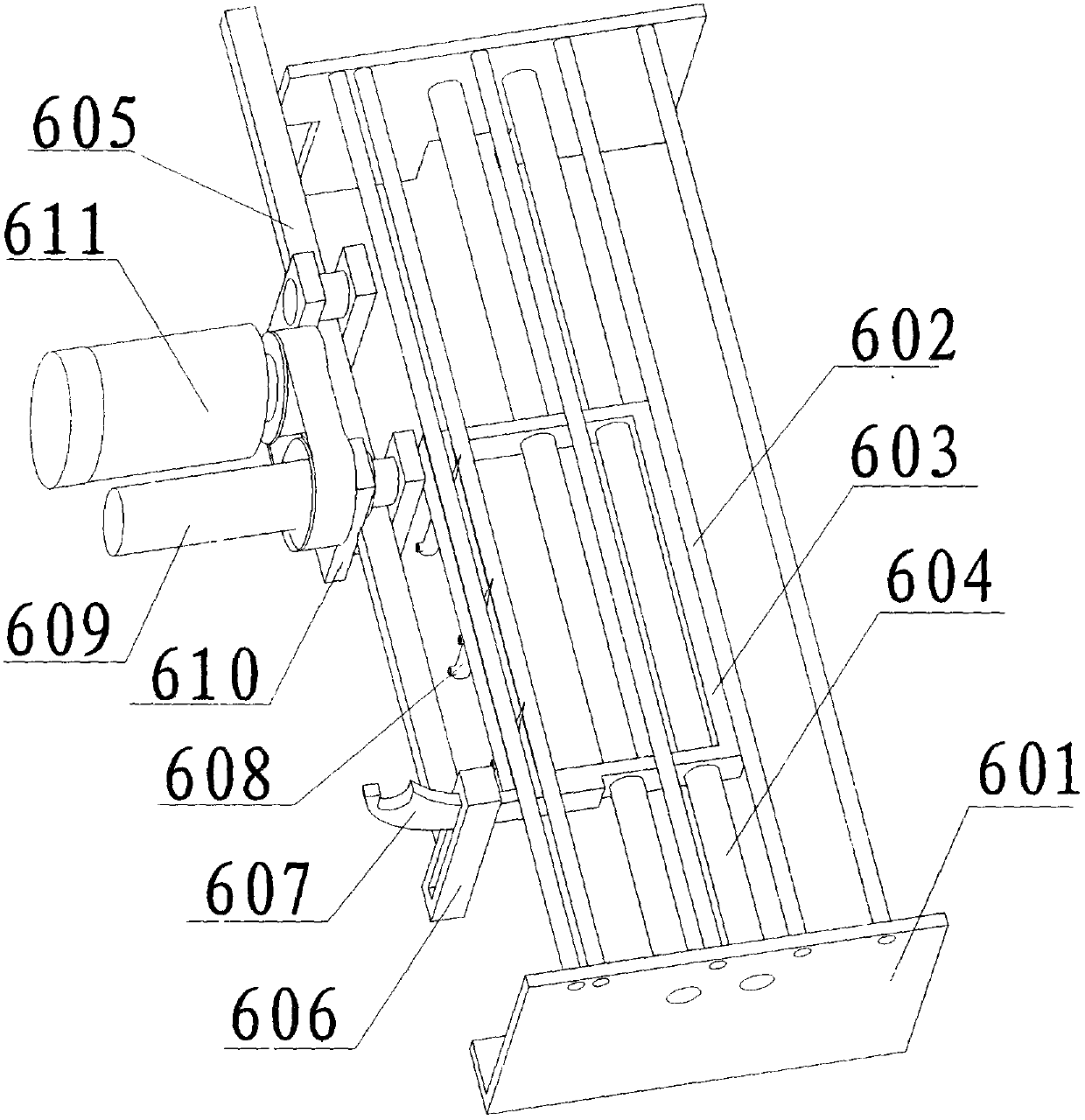

[0041] combine Figure 1 to Figure 6 , a flat roll paper tube machine, comprising a frame 1, a paper unloading device 2 connected to the frame 1, a paper guide device 3, a slurry coating device 4, a paper cutting device 5, a paper feeding and removing device 6, a roll tube device 7 and pipe cutting device 8, the sizing device 4 includes a sizing roller 404, a paper passing device 408 is fixedly arranged between the sizing device 4 and the paper cutting device 5, the paper feeding surface of the paper passing device 408 and the top of the sizing roller 404 The surfaces are on the same plane, and the paper output surface of the paper passing device 408 and the paper cutting surface of the paper cutting device 5 are on the same plane.

[0042] A paper passing device 408 is arranged between the sizing device 4 and the paper cutting device 5. After the paper 11 is slurried, it passes through the paper device to prevent the paper containing the slurry on the surface from adhering to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com