Fixed-size standard cutting mechanism for aluminum bottle cap production and processing

A technology of sizing and caps, applied in metal processing machinery parts, manufacturing tools, metal processing equipment and other directions, can solve the problems of uneven size, the aluminum skin does not have a good sizing function, and reduces the quality of processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

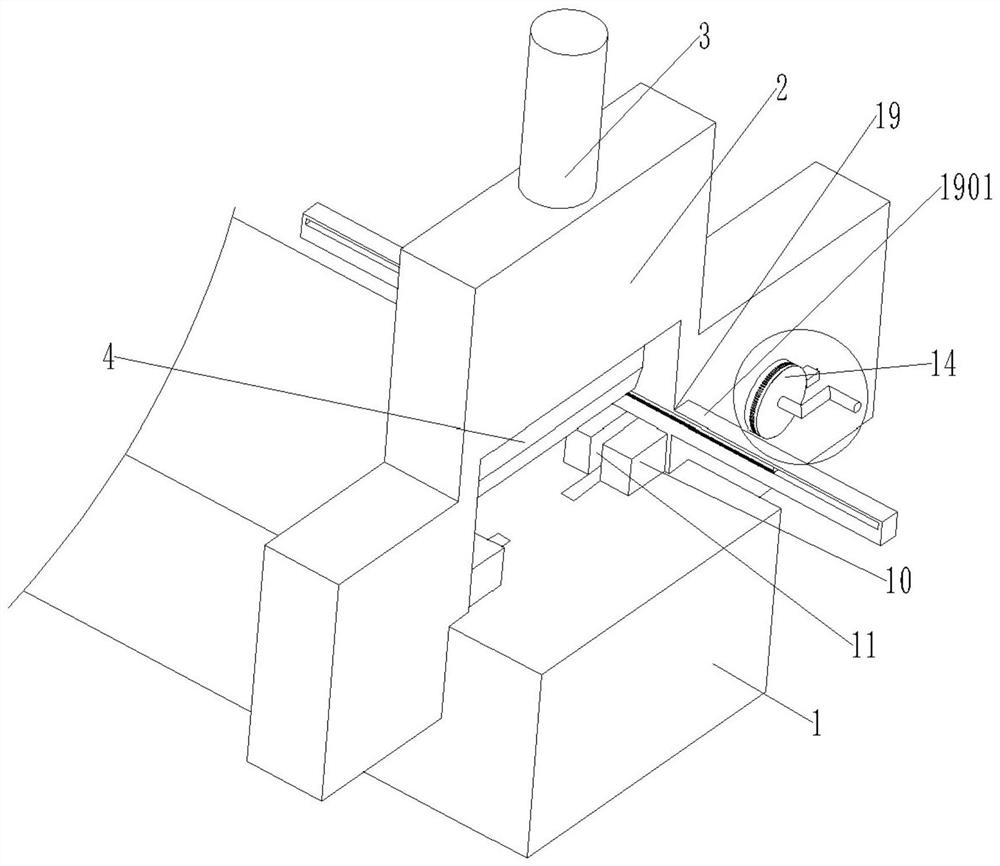

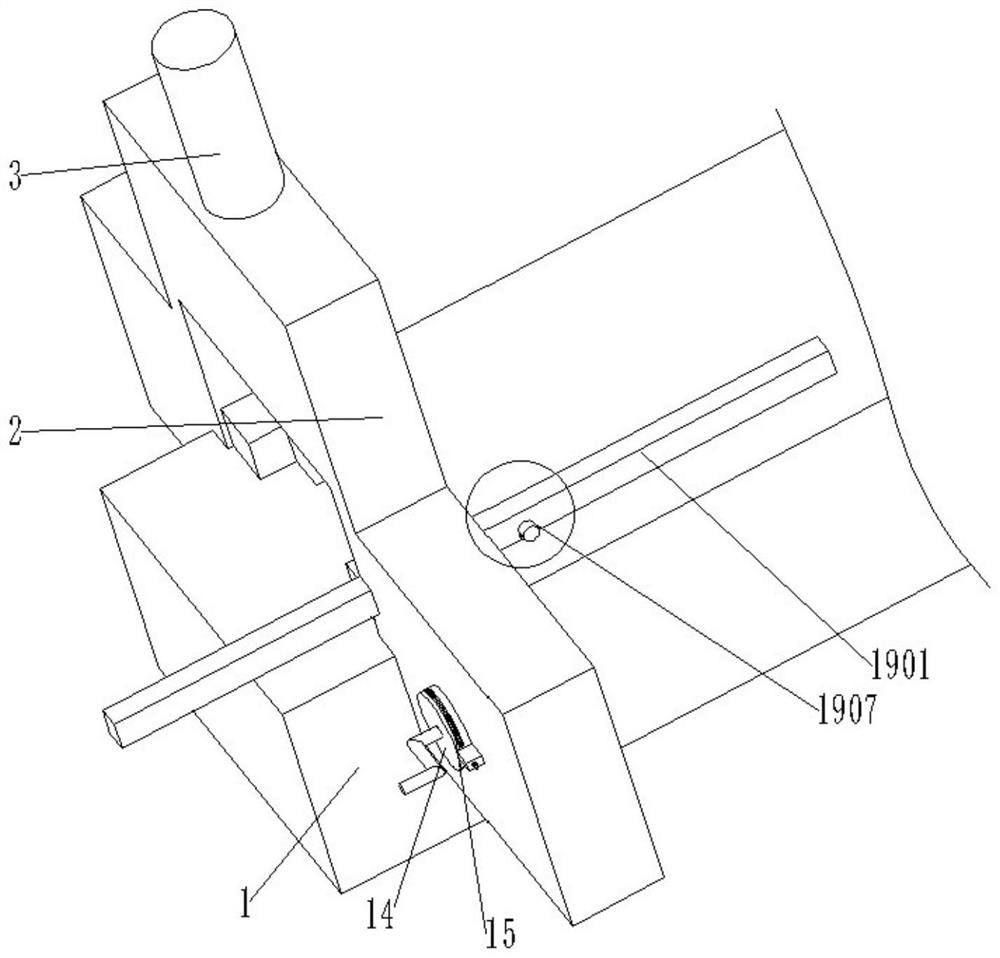

[0023] Specific embodiments: a sizing-cutting mechanism for the production and processing of aluminum bottle caps, including a workbench 1, a fixed frame 2, a telescopic rod 3, a cutting knife 4 and a sizing mechanism 19;

[0024] A fixed frame 2 is arranged on the workbench 1, a telescopic rod 3 is arranged in the fixed frame 2, a cutting knife 4 is arranged at one end of the telescopic rod 3, and a fixed body is arranged on the side of the workbench 1, and a transmission rod is arranged in the fixed body. gear 5;

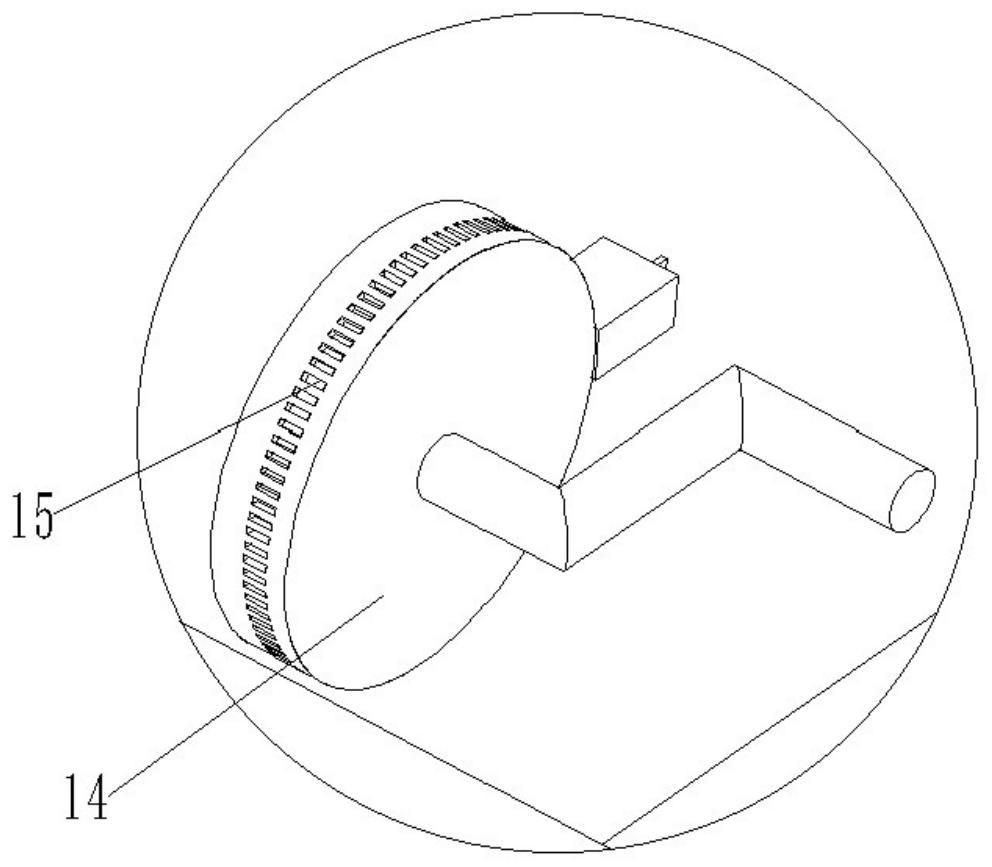

[0025] One side of the transmission gear 5 is provided with a first transmission rack 6, and the other side is provided with a second transmission rack 7, and one end of the first transmission rack 6 is provided with a first bracket 8, a second transmission One end of the rack 7 is provided with a second bracket 9, and one end of the second bracket 9 and the first bracket 8 is provided with a limiting movable block 10, and a through groove 11 is arranged in the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com