High-frequency preheating angle steel angle opening and closing machine

A technology of high-frequency preheating and opening and closing angles, which is applied in the field of power pole and tower processing equipment, can solve problems such as incomplete processing, cracking of angle steel, and poor quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

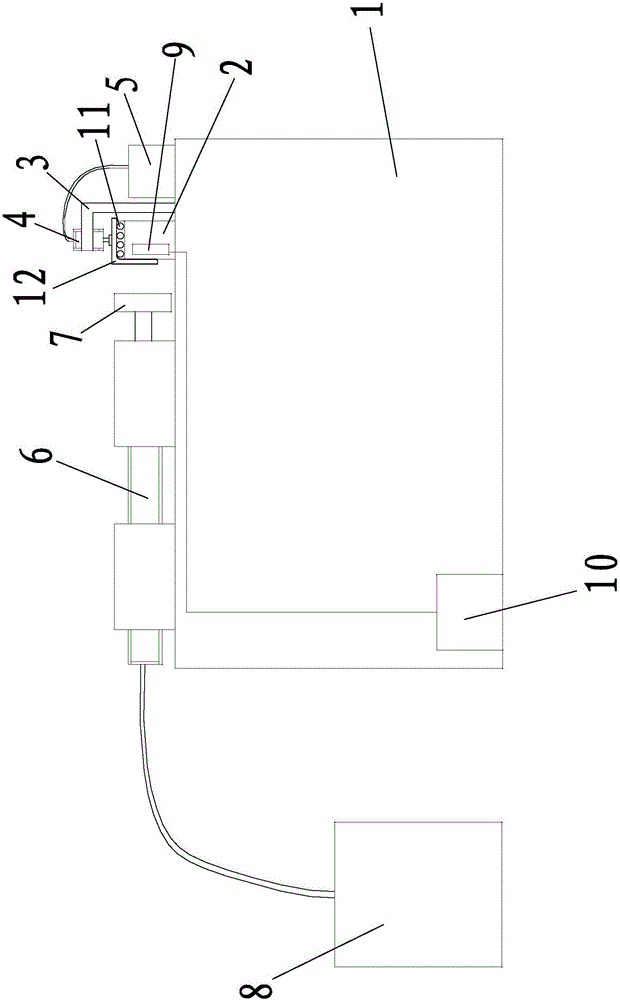

[0009] Such as figure 1 As shown, the present invention is provided with an angle steel support block 2 on one side of the upper plane of the frame 1, and a compression oil cylinder 4 is longitudinally supported by a support 3 above the angle steel support block 2, and the auxiliary hydraulic station 5 is arranged on the outside of the support 3. The auxiliary hydraulic station 5 is connected to the pressing cylinder 4 through a high-pressure oil pipe, and the stamping cylinder 6 is arranged laterally on the other side of the upper plane of the frame 1, and the punch 7 on the stamping cylinder 6 is connected to one side of the angle steel support block 2 Correspondingly, the main hydraulic station 8 is arranged on one side of the frame 1, and the main hydraulic station 8 is connected with the stamping cylinder 6 through a high-pressure oil pipe. A heating block 9 is arranged inside the angle steel support block 2, and the heating block 9 is connected with an electromagnetic he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com