Novel casting mold cleaning device

A technology for casting molds and cleaning devices, which is applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of easy introduction of impurities, affecting the quality of castings, and unclean mold cleaning, so as to achieve thorough cleaning , to ensure the quality of production and processing, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

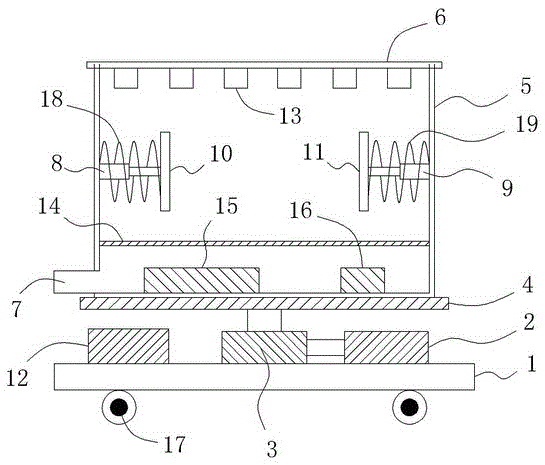

[0014] Such as figure 1 As shown, a novel casting mold cleaning device includes a base 1 on which a motor 2 and a reducer 3 connected to the output shaft end of the motor 2 are respectively arranged on the base 1, and the output shaft of the reducer 3 is arranged vertically upward, and A tray 4 is also provided at the output shaft end of the reducer 3, and a cleaning cylinder 5 is also installed on the tray 4. A cylinder cover 6 is arranged on the top of the cleaning cylinder 5, and a water inlet is provided on the cylinder cover 6. The bottom of 5 is provided with water outlet 7, is respectively provided with the left telescopic rod 8 of horizontal arrangement and the right telescopic rod 9 on the left and right sides of cleaning cylinder 5, is all provided with locking on left telescopic rod 8 and right telescopic rod 9. Bolt, also be provided with the left arc-shaped plate 10 that protrudes to the left at the right end of left telescopic link 8 simultaneously, also be provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com