Continuous indigo dyeing device and dyeing method for cotton sliver

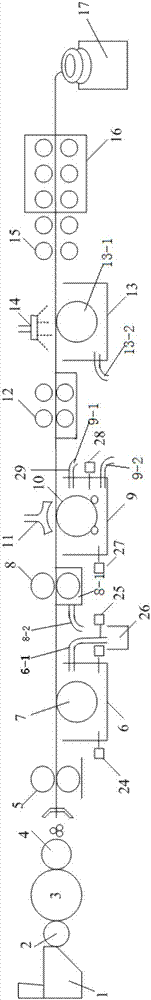

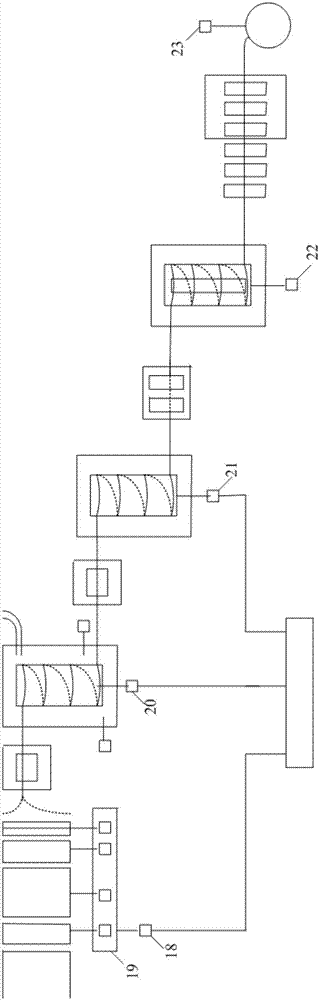

A dyeing device and sliver technology, which can be used in deburring devices, liquid/gas/steam fiber/sliver/roving processing, textiles and papermaking, etc. It can solve the problem that the equipment occupies a large area and cannot form the yarn-dyed effect of denim fabrics , low cost and other issues, to achieve the effect of small equipment footprint and length, reduce the impact of accidental drawing tension, and ensure the quality of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

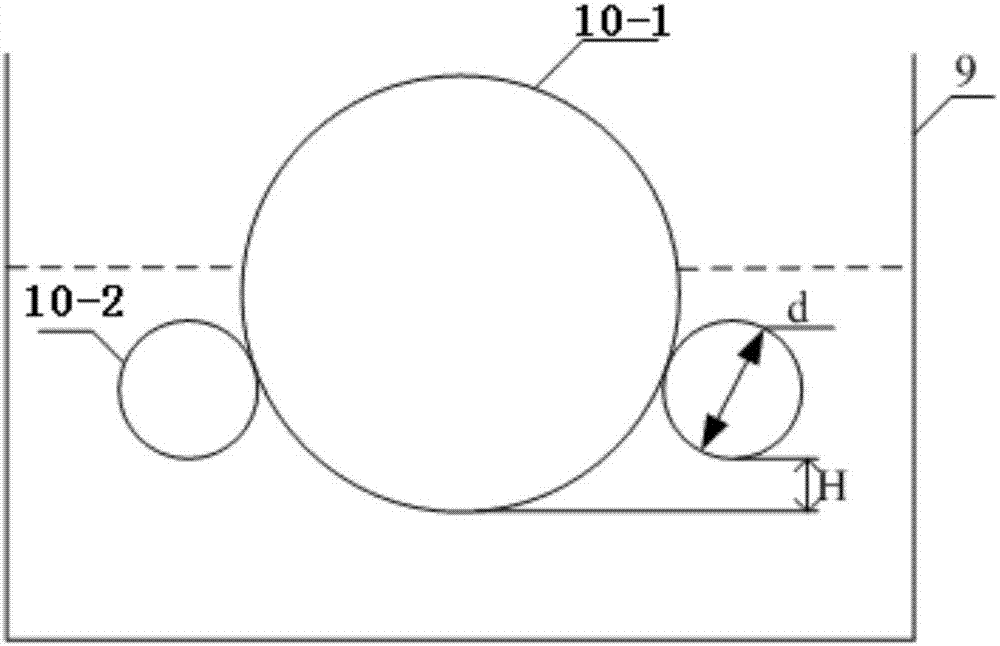

[0046] The raw cotton that has been cleaned is fed through the raw cotton feeding device 1, and the large impurities and cottonseed are removed by the opening rod 2 covered with metal card clothing, and further separated by the carding roller 3 covered with elastic card clothing. Comb to remove neps and linters, use collecting sliver making device 4 to peel off and collect and prepare sliver with a weight of 5 g / m. After the cotton sliver is initially wetted by the wetting device 5 with a pair of stainless steel metal rollers, it is fed and spirally wound in the stainless steel scouring tank 6. The tube has a length of 100 cm and a diameter of 50 cm. It has a circular mesh 304# stainless steel scouring rotary drum 7 On the surface, a total of 7 circles are wound, the sliver spacing is 3cm, and the scouring liquid is used for scouring in the scouring tank. The scouring process conditions: scouring liquid: NaOH: 5.5g / l, hydrogen peroxide: 11g / l, sub Sodium bisulfate 0.6% (o.w.f)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com