Plastic bottle aluminum cap production raw material pretreatment device

A pretreatment device and technology for plastic bottles, which are applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc. Problems such as pretreatment, affecting the production and processing efficiency and production quality of aluminum covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

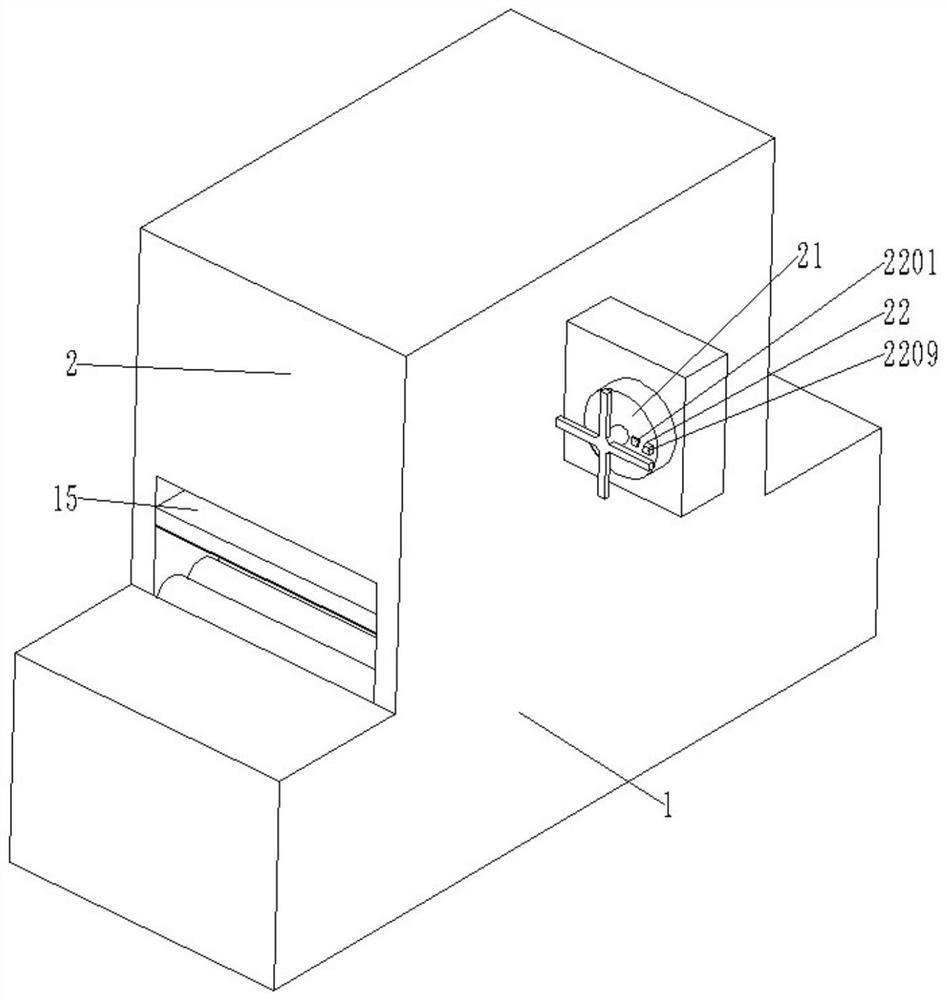

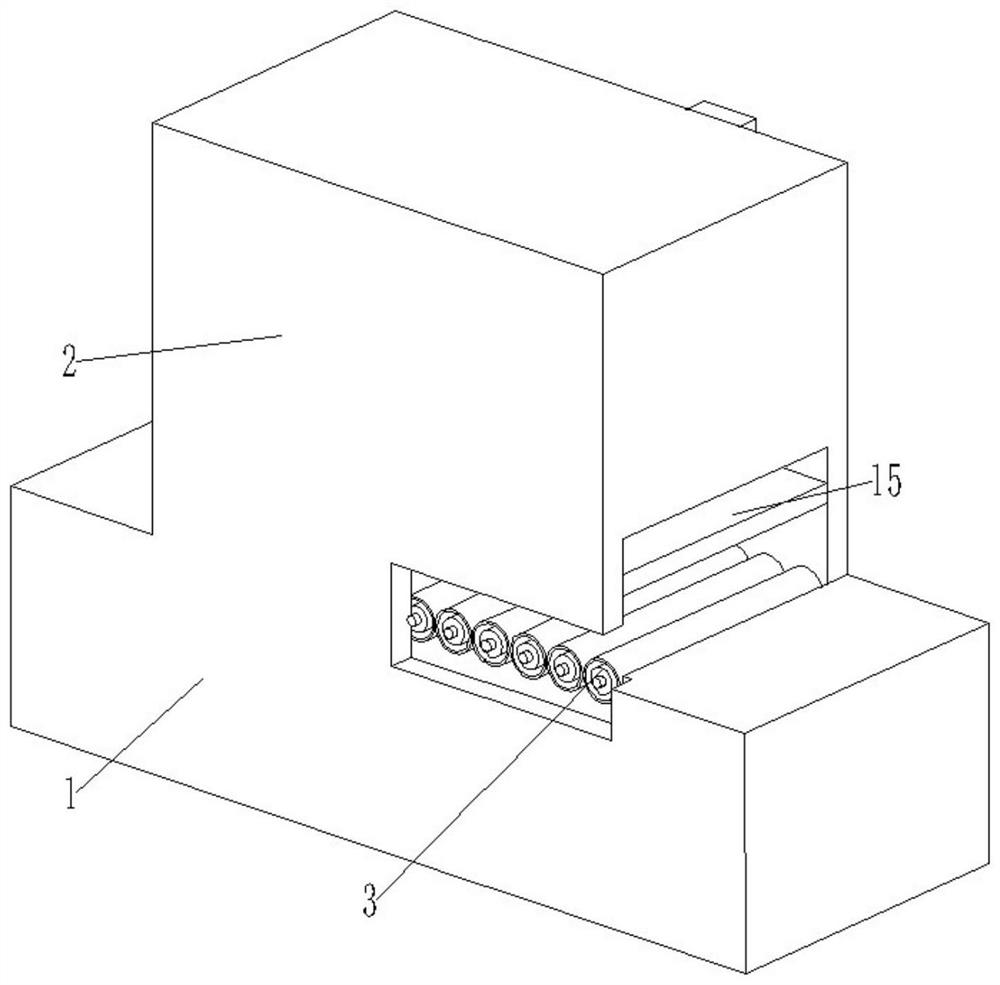

[0024] Specific embodiments: a raw material pretreatment device for the production of aluminum caps for plastic bottles, including a pretreatment workbench 1, a box body 2, a drum 3, a sleeve 10, an extrusion plate 15, and a positioning mechanism 22;

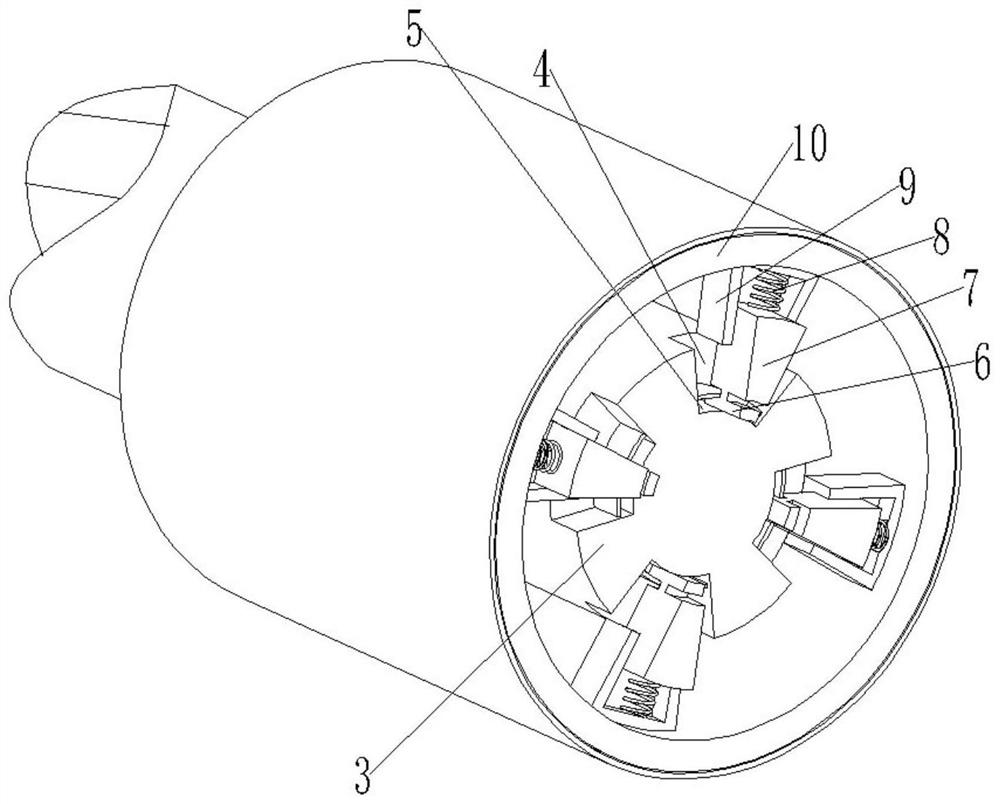

[0025] The pretreatment workbench 1 is provided with a box body 2, and the pretreatment workbench 1 is equidistantly inserted with a drum 3, and the outer wall of the drum 3 is equidistantly provided with arc-shaped movable grooves 4, and the arc-shaped movable groove 4 A movable chute 5 is provided, and an arc-shaped movable block 6 is arranged for movable connection in the movable chute 5;

[0026] The arc movable block 6 is provided with a first arc extruding block 7, and one end of the first arc extruding block 7 is connected with a first extruding spring 9, and the other end of the first extruding spring 9 is arranged on the second arc. shaped extrusion block 8, and the first arc-shaped extrusion block 7 is movably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com