Silicon wafer conveying equipment on sputtering table and using method

A technology for conveying equipment and silicon wafers, which is applied in the directions of conveyor objects, transportation and packaging, sustainable manufacturing/processing, etc. It can solve the problems such as the inability to effectively improve the processing efficiency of silicon wafers and the damage of silicon wafers, so as to improve the processing efficiency of silicon wafers. , The effect of preventing silicon wafer damage and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

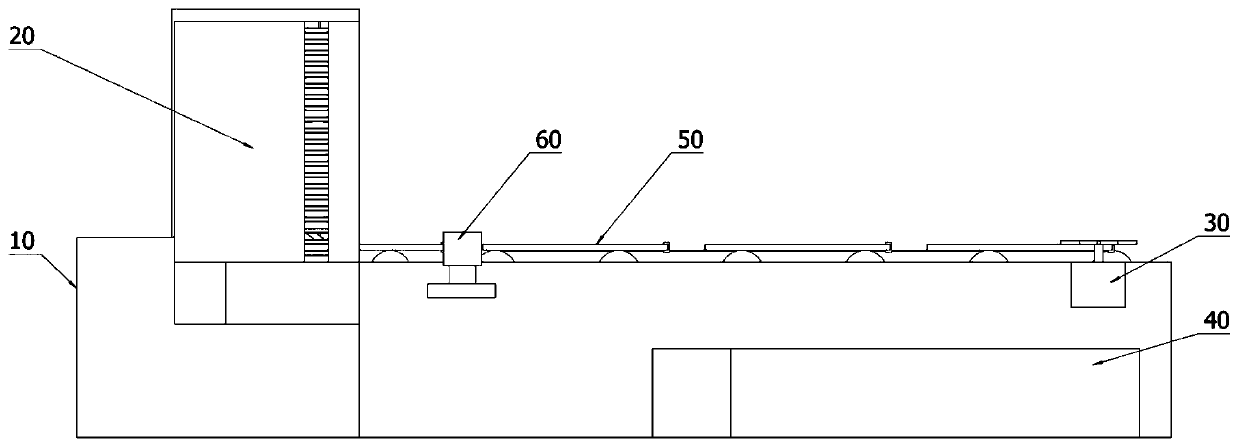

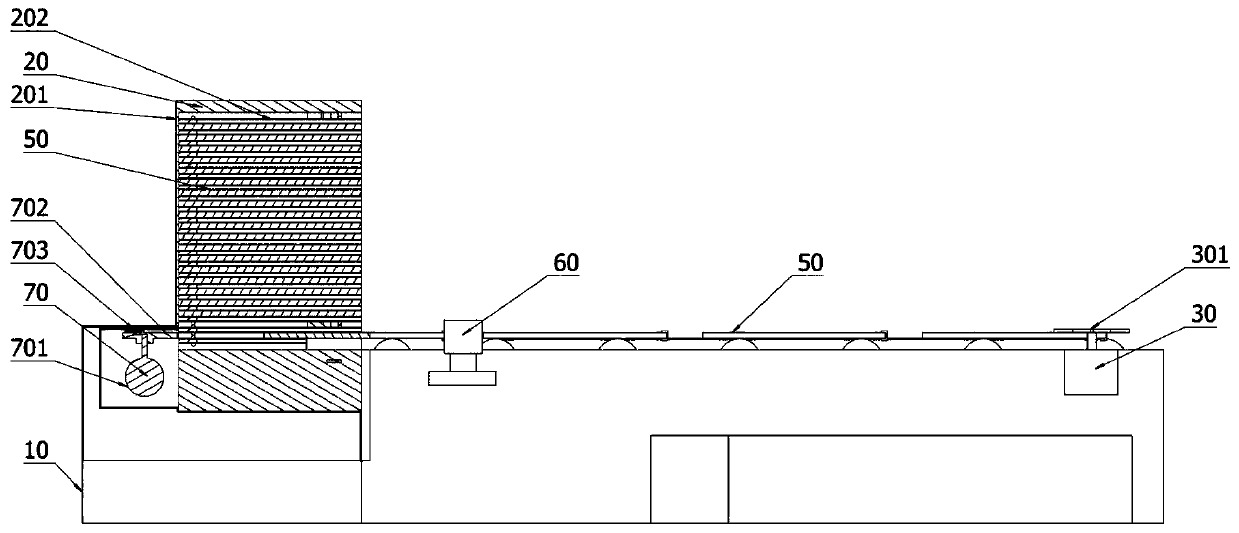

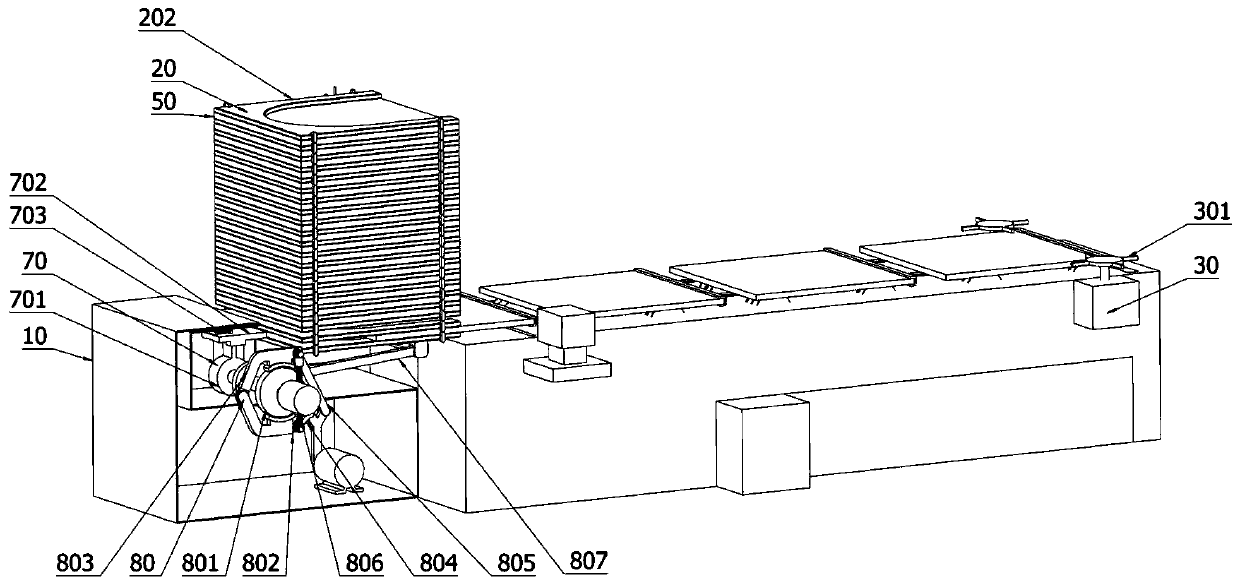

[0050] Such as figure 1 , 2 As shown, this embodiment discloses a silicon wafer 50 conveying device, comprising: a body 10, a placement device 20, a housing 201, a lead-out device 70, a lead-out plate 702, and a driving device 80. The body 10 is arranged on a plane, and the body 10 Inside is provided with delivery wheel 102, delivery wheel 102 is fixedly connected with body 10; placement device 20, placement device 20 is arranged on one side of body 10, placement device 20 is connected with body 10, placement device 20 comprises: shell 201, shell 201 sets Above the body 10, the shell 201 is connected with the body 10, and the inside of the shell 201 is hollow; the plate 202 is placed, and the plate 202 is arranged inside the shell 201, and a gap is provided between the plate 202, and the space of the plate 202 is used To store the silicon wafer 50; the deriving device 70, the deriving device 70 is arranged inside the body 10, the deriving device 70 is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com