Heating and cooling device of bonding machine

A technology of cooling device and bonding machine, which is applied in the field of bonding machine, can solve the problems of long cooling time, scald when taking out the wafer, and difficulty in heating and cooling devices, and achieve the effects of high safety, accelerated cooling speed, and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] Based on the bonding machine heating and cooling device provided in the first embodiment of the present application, the second embodiment of the present application proposes another bonding machine heating and cooling device. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

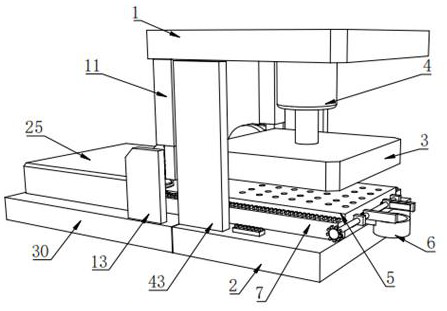

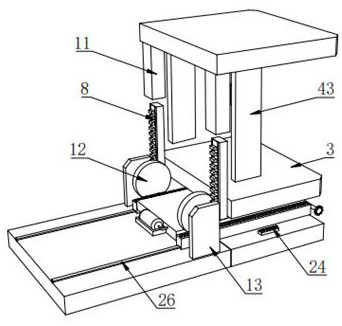

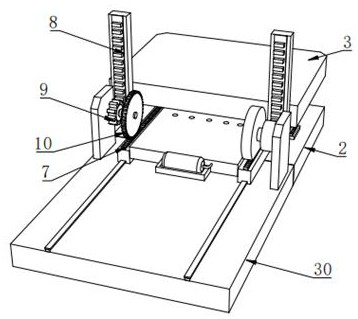

[0049] Attached below Figure 7-Figure 9 and Embodiment The second embodiment of the present invention will be further described.

[0050] The upper side of the push block 5 is provided with a heat dissipation plate 1 31, and the lower end of the push block 5 is fixedly connected with a heat dissipation plate 2 42, and the heat dissipation plate 2 42 can be fixed on the lower end of the push block 5 in the form of point contact, so as to ensure acceptance of air cooling, A compression spring 37 and a telescopic tube 38 are fixedly connected between the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com