Device for pressing elevator handrail belt into die

A technology of handrails and molds, which is applied in the field of devices where elevator handrails are pressed into moulds, which can solve the problems of harmful gases harmful to the human body, accidental injuries to processing personnel, and high labor intensity, so as to reduce the harm of human body burns and work done , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

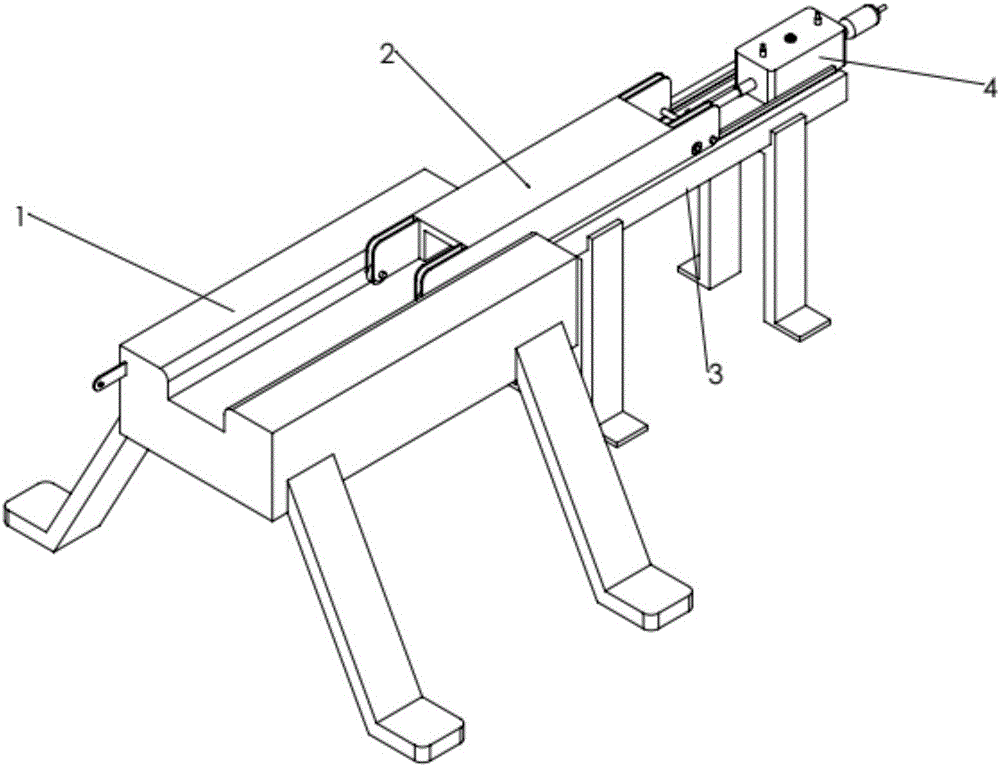

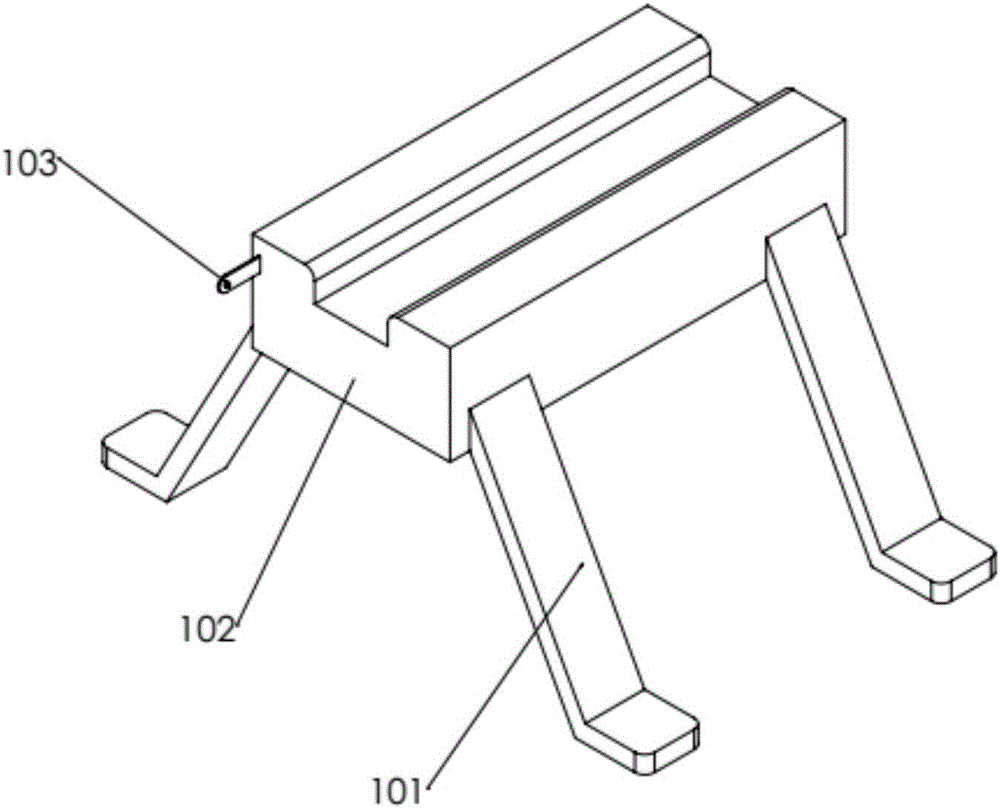

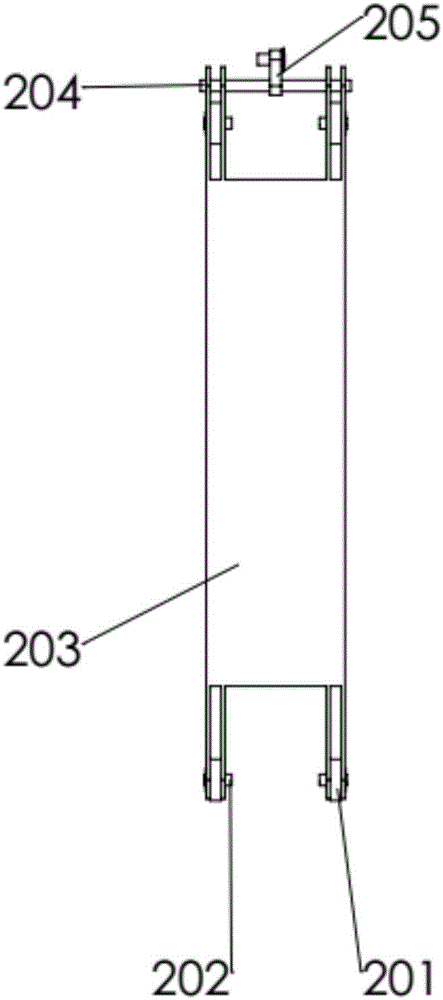

[0015] A device for pressing the handrail of an elevator into a mould, which is composed of a mold frame 1, a mold device 2, a mold support frame 3 and an air pressure device 4, and the mold frame 1 is composed of four mold legs 101 , mold groove 102 and photoelectric sensor 103, and described mold device 2 is made up of four rollers 201, five fixing nails 202, steel mold 203, cross bar 204 and semicircle joint 205, and described mold supports Frame 3 is made up of two mold supporting legs 301 and guide groove body 302, and described air pressure device 4 is made up of push rod 401, sleeve rod 402, air cylinder 403, lubricator 404, oil inlet valve 405, advance Composed of air valve 406, start button 407 and rear air intake valve 408, four die legs 101 are installed below the die groove 102 at intervals, photoelectric sensors 103 are installed at the front of the die groove 102, and four rollers 201 pass through the fixed The nail 202 is installed on the steel mold 203, the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com