Sterilizing tank for sterile can processing

A technology for sterilizing cans and cans, which is applied in the direction of conveyor objects, chemistry, and bottle filling, etc. It can solve the problems that cans cannot be sterilized and disinfected, and the impact of use, so as to reduce the threat of burns and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

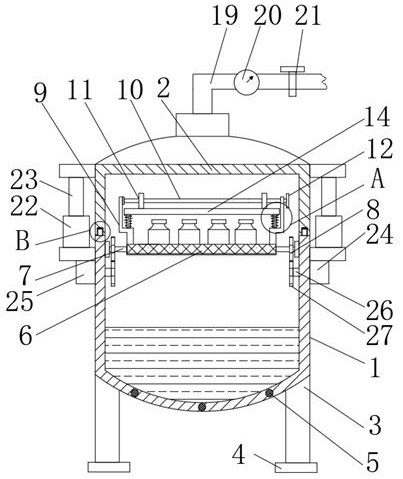

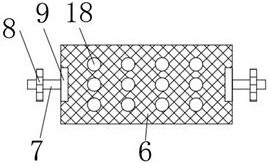

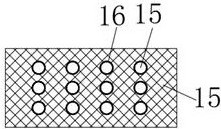

[0029]Such asFigure 1-5As shown, the embodiment of the present invention provides an aseptic can processing sterilization tank, which includes a device main body 1, an end cover 2. The inner bottom of the device main body 1 is provided with a heating assembly 5, which can be set as a heating resistance wire or a heating tube for To evaporate the solution, a placing plate 6 is arranged inside the main body 1 of the device for placing canned bottles to be sterilized. The upper surface of the placing plate 6 and close to both sides are fixedly connected with vertical plates 9 and the surface of the vertical plates 9 is fixedly connected with telescopic rods. 13. While the cover plate 14 has limit support, the restoring spring 17 is bent, and the top of the telescopic rod 13 is fixedly connected with a cover plate 14 for limiting the canned bottle. The vertical plates 9 are rotated between The adjusting rod 10 is connected to the outer surface of the adjusting rod 10 and is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com