Debris flow blocking dam with automatic desilting function and building and using method

A debris flow and functional technology, applied in the field of debris flow protection engineering, can solve the problems of water sand and silt being unsuitable, and achieve the effects of convenient construction, prolonged service life and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

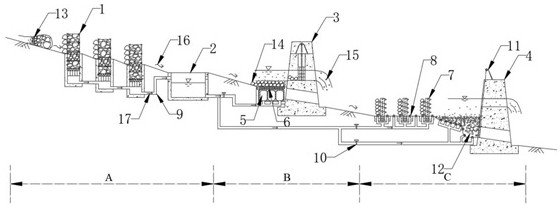

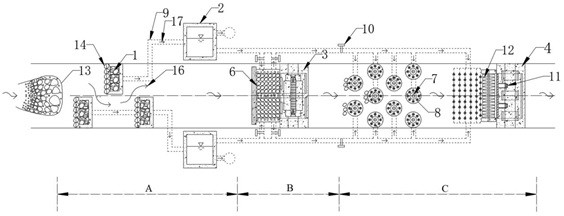

[0055] A kind of debris flow retaining dam with automatic dredging function of the present embodiment, such as figure 1 with figure 2 As shown, a debris flow retaining dam with automatic desilting function includes a debris flow energy dissipation water collection section A arranged upstream of the debris flow ditch, a large-grain stone block cleaning section B in the middle of the debris flow ditch, and a small debris flow ditch downstream of the debris flow ditch. Particle mud and sand blocking cleaning section C.

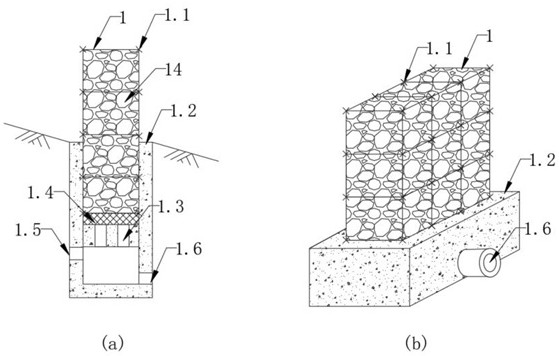

[0056] Debris flow energy dissipation water collection section A includes multiple energy dissipation water collection gabions 1 and multiple water collection basins 2 arranged in a staggered manner; Figure 3-4 As shown, the energy-dissipating water-collecting gabion 1 fixes the large-grained stones 14 into a cube by binding the mesh cage 1.1, and is arranged on the gabion base 1.2 made of concrete. The gabion base 1.2 is connected with the energy-dissipating ...

Embodiment 2

[0069] This embodiment provides a construction method of the debris flow retaining dam with automatic desilting function described in Embodiment 1, the specific steps are as follows: Step S1: According to the historical hydrogeological data of the debris flow 13 ditch, predict the flow rate of the debris flow 13 in the future , flow velocity parameters; along the flow direction of the debris flow 13, the debris flow 13 energy dissipation water accumulation section, the large particle stone block 14 blocking cleaning section and the small particle sand 15 cleaning section are arranged in sequence from the upstream to the downstream of the debris flow;

[0070] Step S2: Build the gabion base 1.2 and the sump 2 in the energy dissipation and water collection section of the debris flow 13, the gabion bases 1.2 are interlaced in the debris flow 13 ditch, the gabion base 1.2 is provided with the energy dissipation and water collection gabion 1, A permeable geotextile is provided betwe...

Embodiment 3

[0074] This embodiment provides a method for using the debris flow retaining dam with automatic desilting function described in Embodiment 1, and the specific steps are as follows:

[0075] Step S5: Clear stones, close the water pipe switches 10 on all the water delivery pipes 9, and open the water pipe switch 10 of the water inlet of the water-filled rubber body 5, so that the stone sliding body 6 of the stone sliding body 6 assembly and the stop protrusion After abutting, close the water pipe switch 10 of the water-filled rubber body 5 water inlet; start the gate starter 11 of the stone blocking and cleaning dam 3 and the gate starter 11 on the mud and sand cleaning dam to close the gate passage and the sand discharge port 4.2 ;

[0076] Step S6: dredging, start the gate actuator 11 of the stone blocking and cleaning dam 3 and the gate actuator 11 on the mud and sand cleaning dam to open the gate channel and the sand discharge outlet 4.2; close the water inlet of the water-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com