Gas generator forming device and method

A gas generator and molding device technology, which is applied in the direction of molding tools, transportation and packaging, and ejection equipment, can solve the problems of low degree of automation and difficulty in taking out products, and achieve the effects of high degree of automation, simple structure, and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

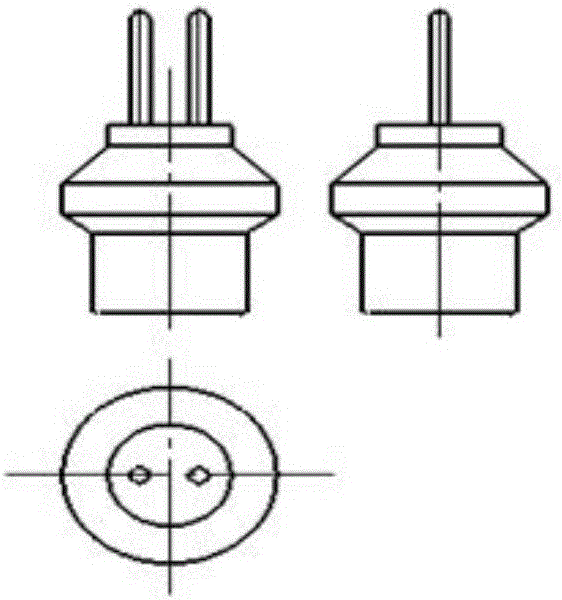

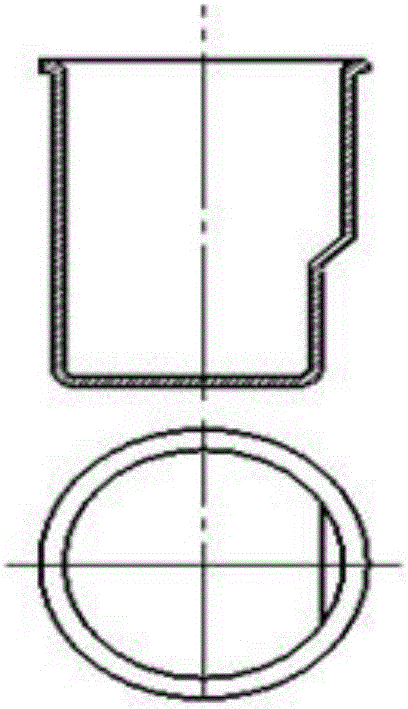

[0037] The gas generator molding device of the present invention includes a pyrotechnic body molding device and a finished product molding device, and the two devices are used as a set. The structure of the gas generator formed by this device includes an electric ignition tube 1, a base 2, and a shell 5, respectively as Figure 1a , 1b , 1c shown.

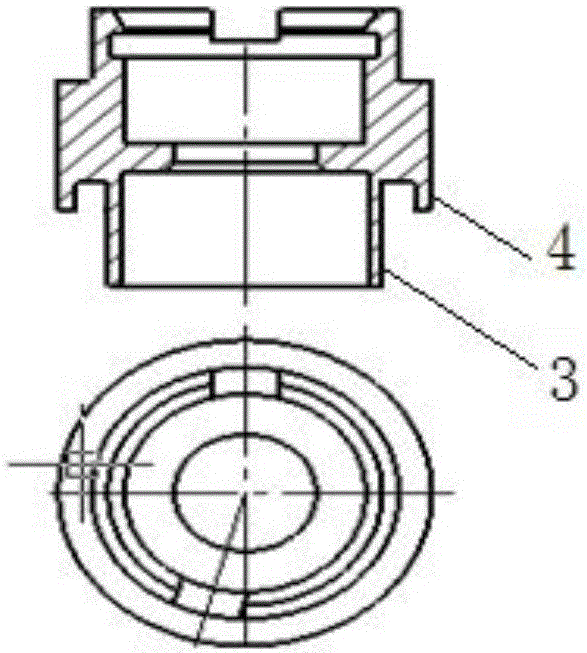

[0038] The firing body molding device is used to assemble the electric ignition tube 1 and the base 2 to form a firing body, including an upper mold 7 and a positioning seat 16. The structure of positioning seat I 6 is as follows figure 2 As shown, its upper surface is provided with a square protrusion 61, which matches the shape of the groove on the base 2, and the base 2 can be fixed on the positioning seat 16 to play the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com