a texturizing machine

A texturing machine and heating device technology, applied in textiles and papermaking, etc., can solve the problems of high production cost, low work efficiency, low uniformity of yarn immersion oil, etc., and achieve the advantages of improving quality, saving labor, and improving cooling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

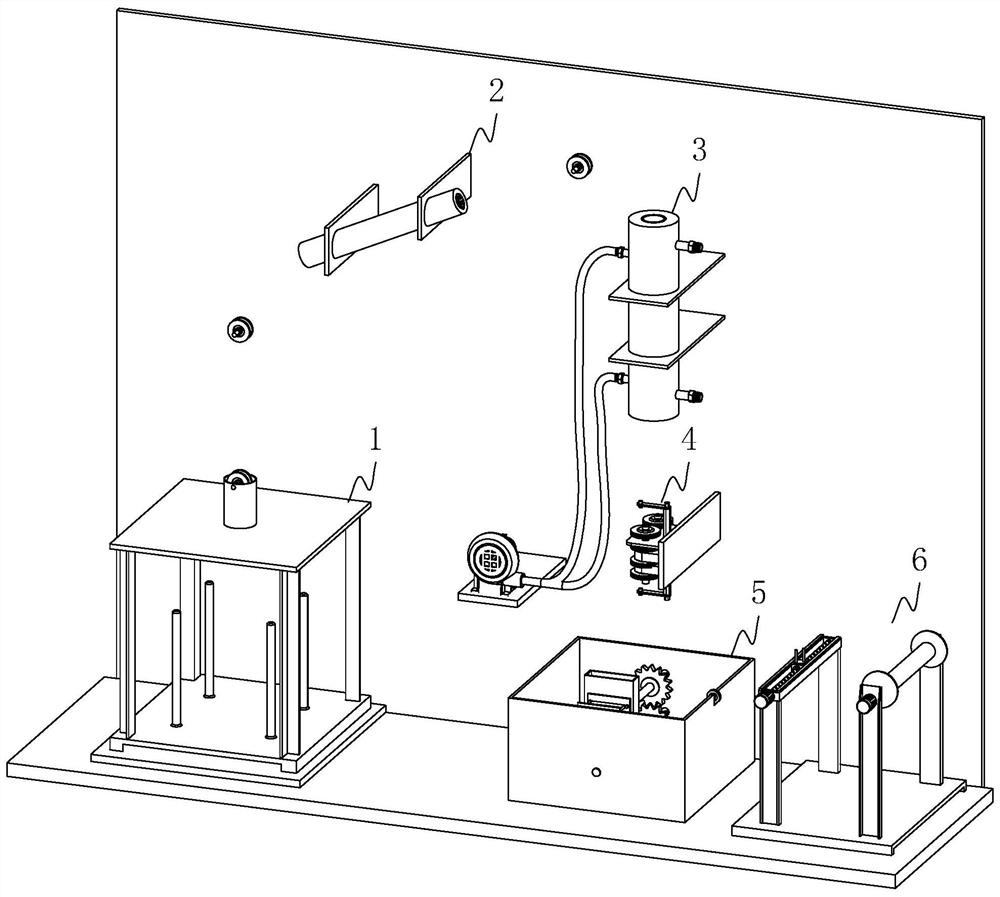

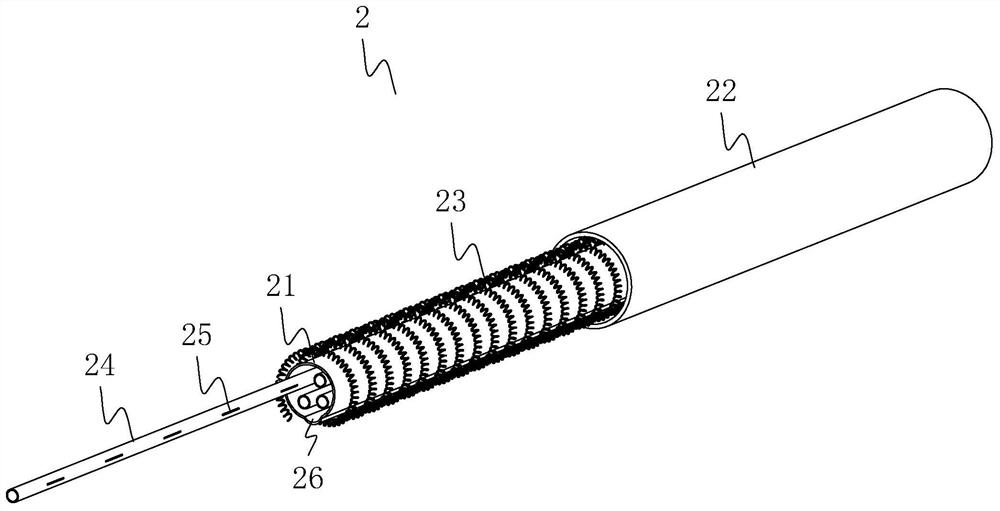

[0040] A texturing machine, such as figure 1 As shown, it includes a yarn feeding device 1 , a heating device 2 , a cooling device 3 , a false twister 4 , an oil immersion device 5 and a yarn receiving device 6 arranged in sequence.

[0041] When using the above-mentioned texturing machine, the yarn is first sent to the heating device 2 by the yarn feeding device 1, and then the yarn is heated by the heating device 2, and then the yarn is cooled by the cooling device 3, and then passed through false twisting The device 4 twists the yarn so that the yarn has certain elasticity, and then the yarn is oil-immersed through the oil immersion device 5 , and finally the oil-immersed yarn is collected by the yarn receiving device 6 .

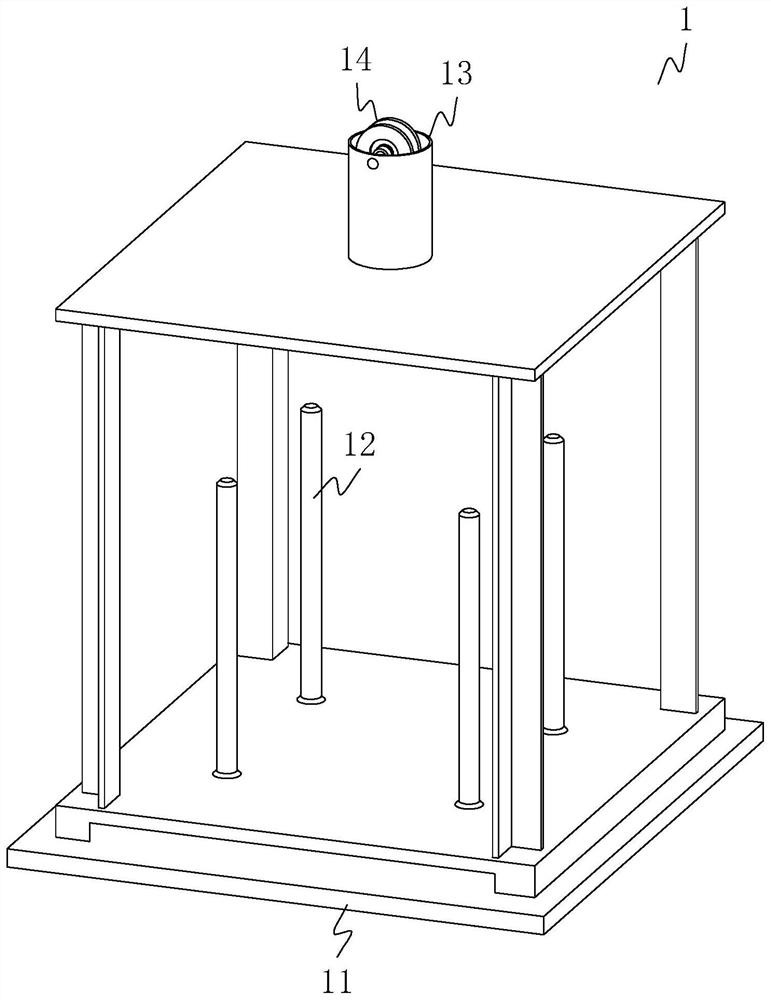

[0042] like figure 2 As shown, the yarn feeding device 1 includes a mounting frame 11, a plurality of mounting rods 12 vertically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com