Low-temperature frying equipment and method for frying fried food

A low-temperature frying and equipment technology, applied in the direction of oil/fat baking, etc., can solve the problems of affecting the service life of oil, low production volume, small vacuum area, etc., reducing workload, increasing single output, and ideal vacuum degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

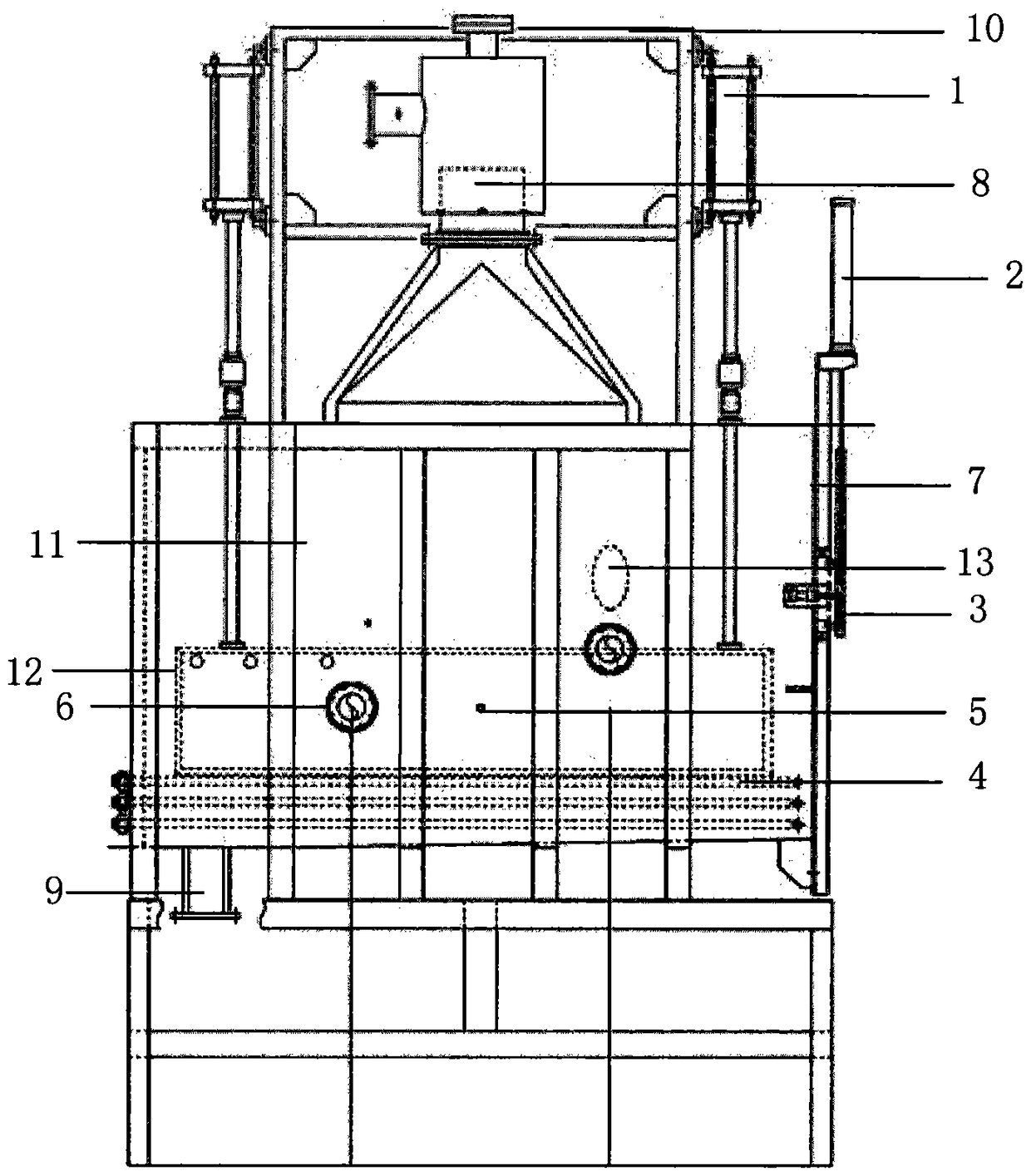

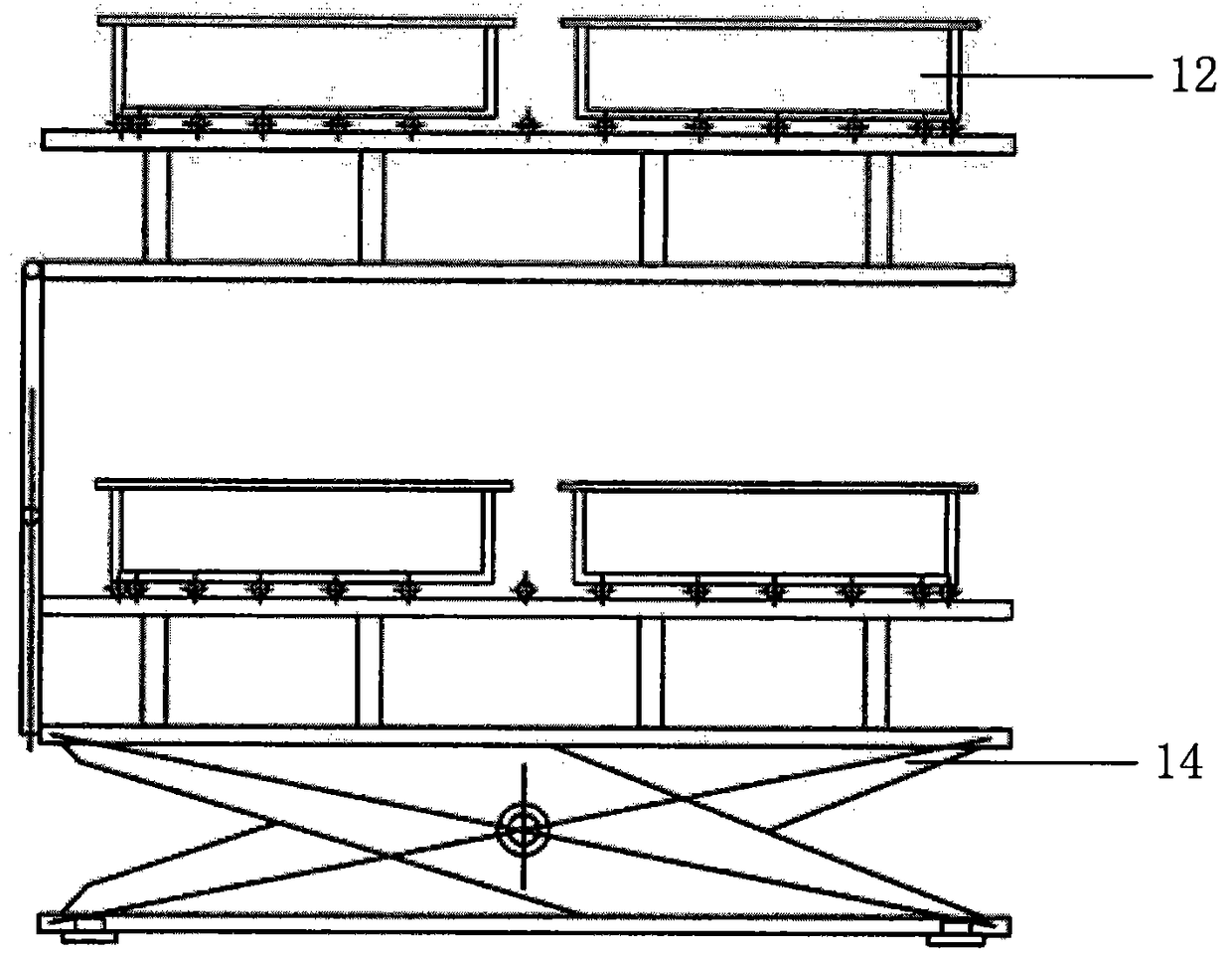

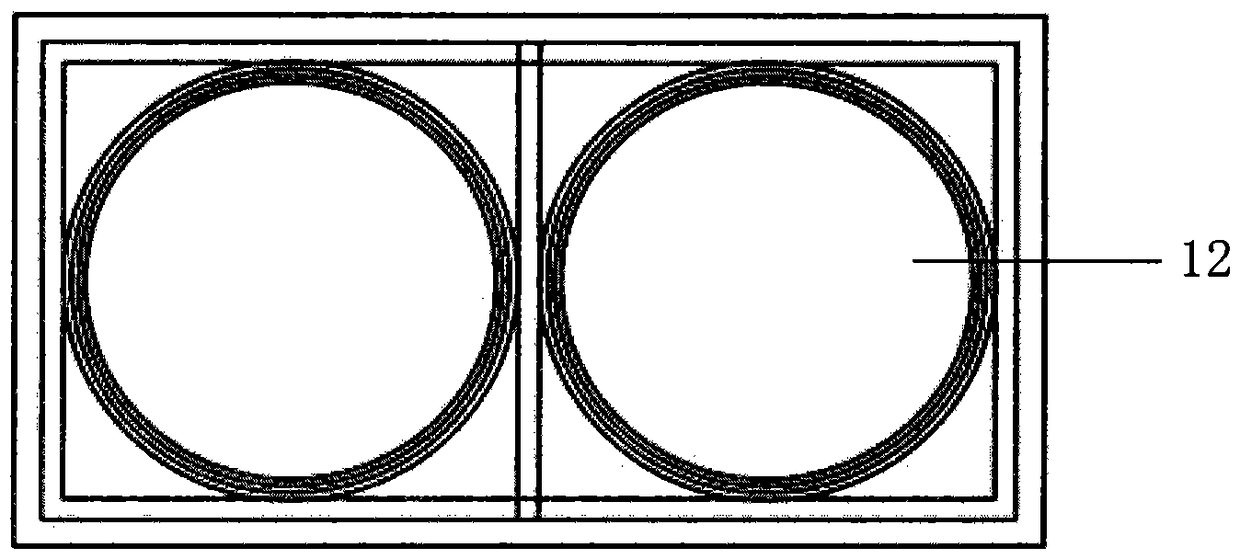

[0044] Such as Figure 1 to Figure 3 As shown, the low-temperature frying equipment mainly includes a frying tank 11 of a square structure, an inlet / outlet door 7 and an oil inlet / outlet 9 communicated with it, a heating pipe 4 arranged inside it, and a frying tank 11 connected to it. The vacuum device 8 that makes the inside of it reach a vacuum state also includes a frying master cylinder 1 for adjusting the frying position, an inlet / outlet door cylinder a2 for driving the inlet / outlet door to descend or rise, The inlet / outlet door cylinder b3 used to drive the inlet / outlet door to open or close, the oil leveler 6 for detecting the oil level, the thermometer 5 for detecting the oil temperature, and the oil temperature signal for receiving , And control the electromagnetic valve 10 of the main frying cylinder 1, the inlet / outlet door cylinder a2 and the inlet / outlet door cylinder b3.

[0045] Wherein, the heating pipe 4 , the thermometer 5 and the oil leveler 6 are all arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com