Rolling oiling station and control system and operation method thereof

A technology of oiling device and control system, applied in the field of rolling oiling device and its control system, to achieve the effect of convenient operation, convenient installation and strict structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

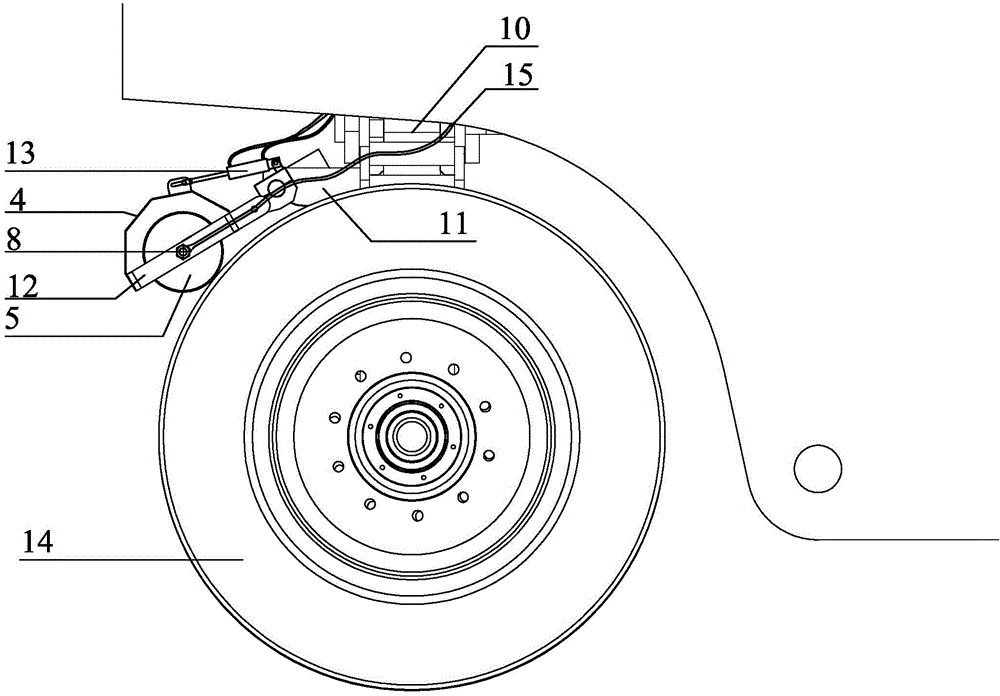

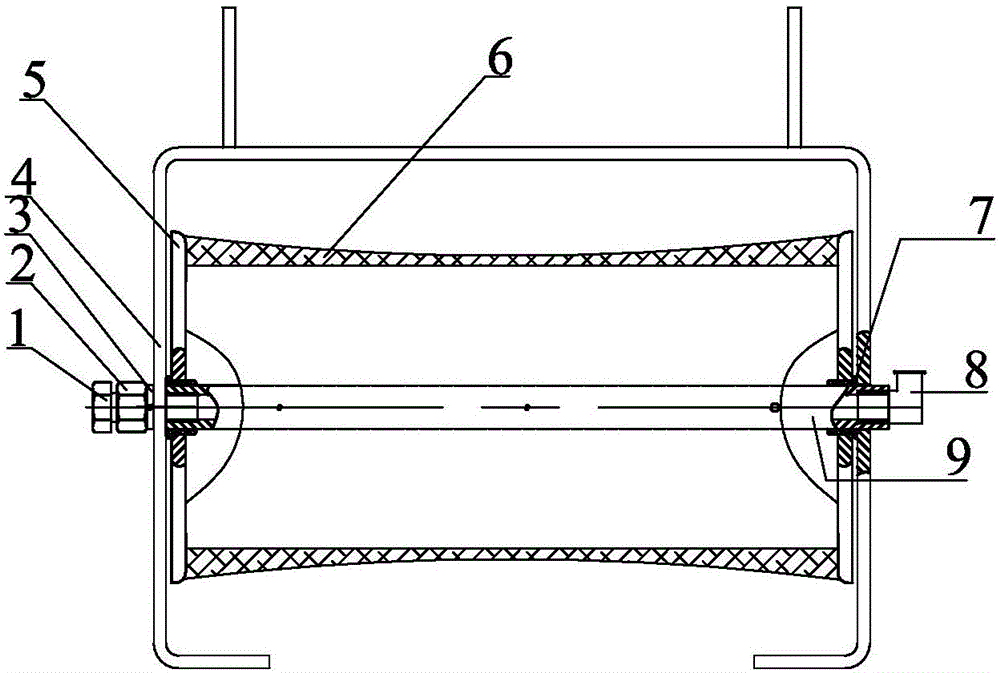

[0034] A rolling oiling device, a mounting seat 11 is arranged above the wheel 14, the lower end of the mounting seat 11 is connected to a support frame 12, a hollow oiling roller 5 is hinged in the middle of the support frame 12, and a through hole is opened on the surface of the oiling roller 5. An oil shield 4 is arranged on both sides and outside of the oil roller 5, the top of the oil shield 4 is connected to one end of the cylinder 13, and the other end of the cylinder 13 is hingedly connected to the mounting seat 11; the cylinder 13 is connected to the air bag of the road roller body connected; the surface of the oil-coated roller 5 is provided with an oil-soaked roller felt layer 6 whose thickness on both sides is greater than that of the center; the oil-coated roller 5 is provided with a hollow shaft 9 with a through hole on the surface, and one side of the shaft 9 passes through the spring Pad 3, fastening nut 2, fixing bolt 1 and support frame 12 are fixedly connecte...

Embodiment 2

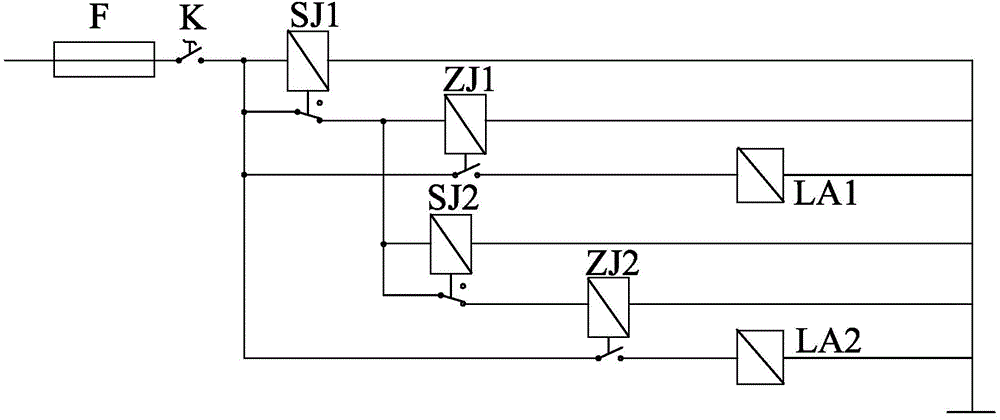

[0039] Adopt the rolling oiling device among the embodiment 1, the operating system that it uses comprises circuit system and gas circuit oil circuit system, and circuit bus terminal is provided with fuse F and main switch K, and circuit is divided into 6 branches, is respectively: ( 1) Connect the rolling time relay SJ1 to ground; (2) The normally closed contact of the rolling time relay SJ1 is connected to the rolling intermediate relay ZJ1 and then grounded; (3) The normally closed contact of the rolling time relay SJ1 and the oiling time The relay SJ2 is connected and then grounded; (4) The normally closed contact of the rolling time relay SJ1 is connected with the normally closed contact of the oil filling time relay SJ2 and then connected with the oil filling intermediate relay ZJ2 and then grounded; (5) The contact of the rolling intermediate relay ZJ1 (6) The contact point of the oil injection intermediate relay ZJ2 is connected to the oil injection electromagnetic valv...

Embodiment 3

[0041] Adopt the operation method of the control system of a kind of rolling oiling device in embodiment 2, operation steps are as follows:

[0042] (1) Close the main switch K;

[0043](2) The rolling time relay SJ1 starts timing, the normally closed contact is closed, the rolling intermediate relay ZJ1 is started, the rolling solenoid valve LA1 is started, the oiled roller 5 is released, and the wheel 14 starts to run;

[0044] (3) At the same time when the rolling time relay SJ1 is closed, the oiling time relay SJ2 starts timing, the normally closed contact is closed, the rolling intermediate relay ZJ1 is started, the oiling solenoid valve LA2 is started, and the oiling roller 5 is filled with oil through the thin oil pipe 15 ;

[0045] (4) Stop oiling after 5 seconds of oiling;

[0046] (5) After the oil roller is applied on the tire for 3 minutes, the normally open switch of the pull roller time relay SJ1 is closed, the normally closed contact is disconnected, the oil r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com