Full-automatic circulating oil injector

An oil filling machine, fully automatic technology, applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of leaking, unable to fill large capacity, etc., achieve high precision, improve oil injection efficiency, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

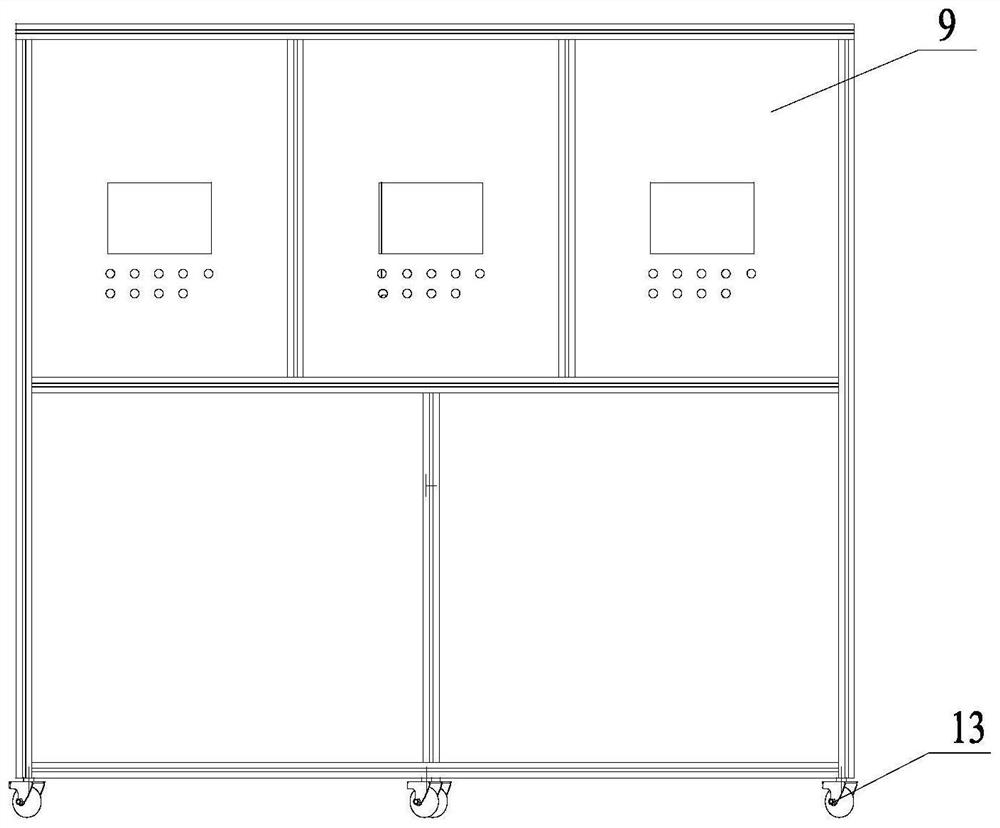

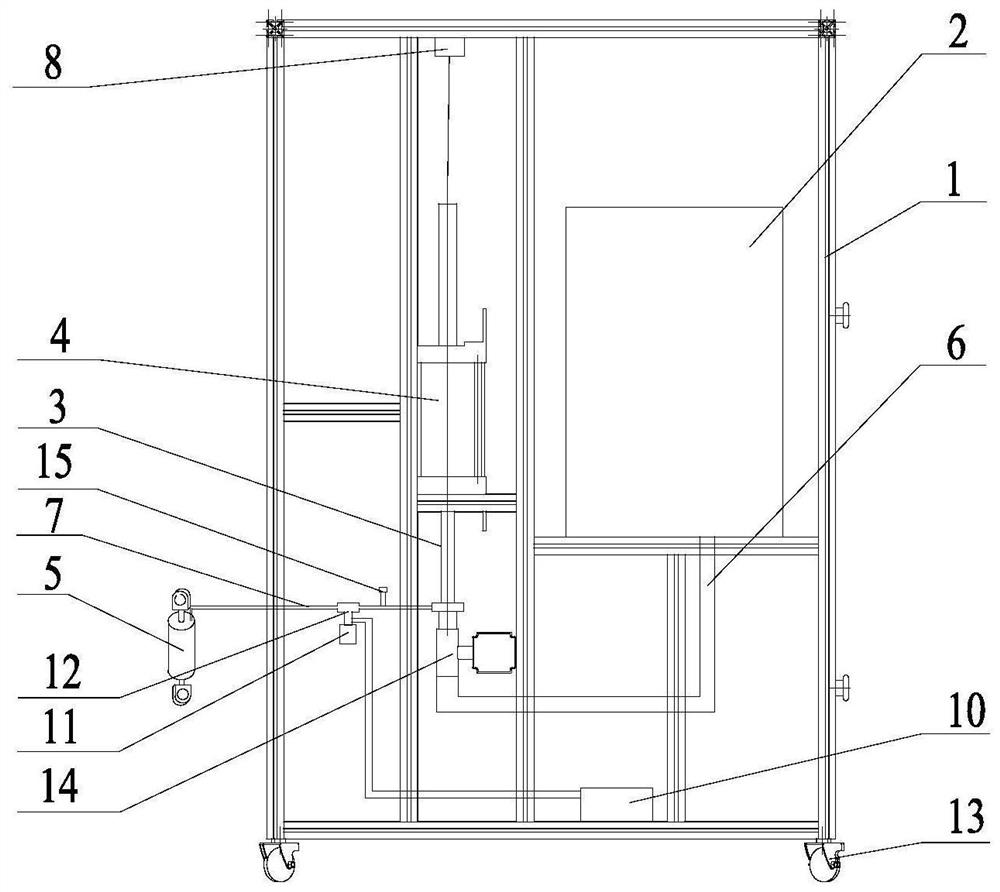

[0015] As shown in the figure: the automatic circulating oil injection machine includes a frame 1, an oil injection assembly, a metering assembly and a control assembly. The frame 1 is provided with a protective shell, and the bottom of the frame 1 can be provided with rollers 13 to facilitate the movement of the frame 1.

[0016] The oil injection assembly includes an oil storage tank 2 installed in the frame 1, an oil injection cylinder 3 and an oil injection cylinder 4, and an oil inlet pipe 6 connected to the oil injection cylinder 3 is provided at the bottom of the oil storage tank 2, and the oil injection cylinder 3 is connected to the oil injection for oil injection and oil intake The cylinder 4 and the oil injection cylinder 3 are provided with an oil injection pipe 7, and the outlet end of the oil injection pipe 7 stretches out from the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com