Rotary table

A technology of turntable and turntable, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc. It can solve the problems of insufficient freedom of workpieces processed by machine tools, and achieve the effects of improving applicability and practicability, reducing looseness, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

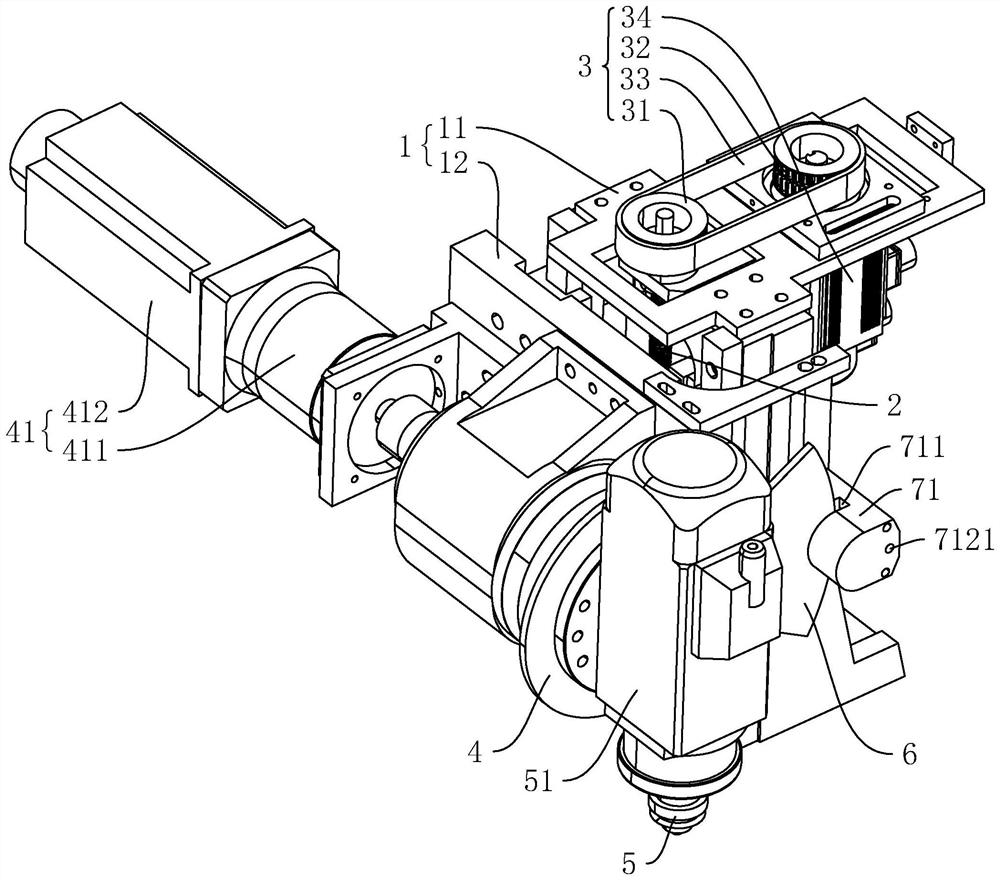

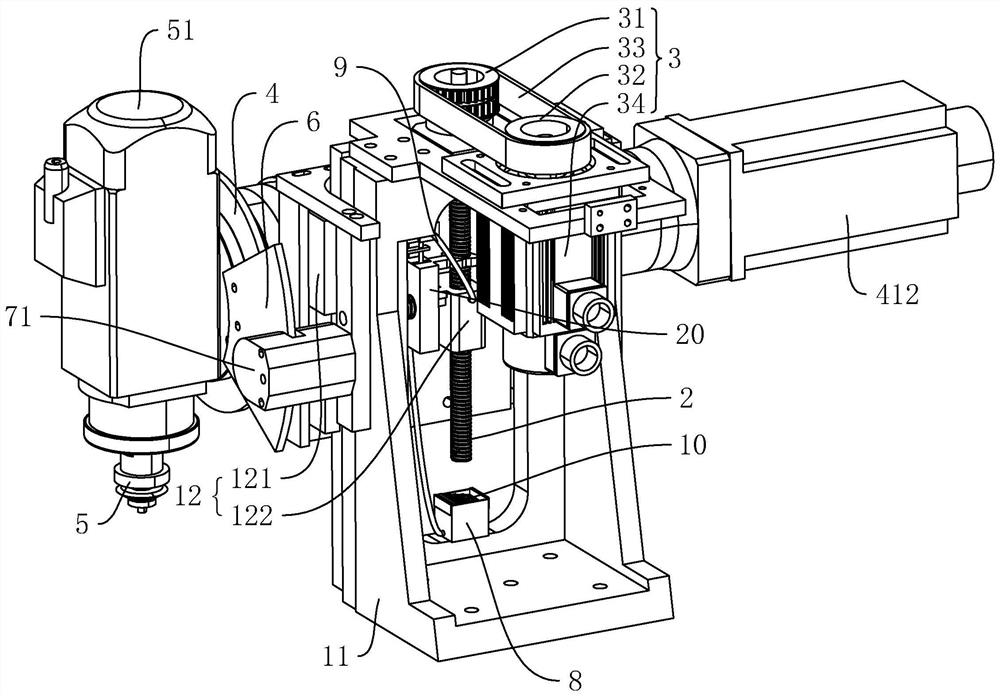

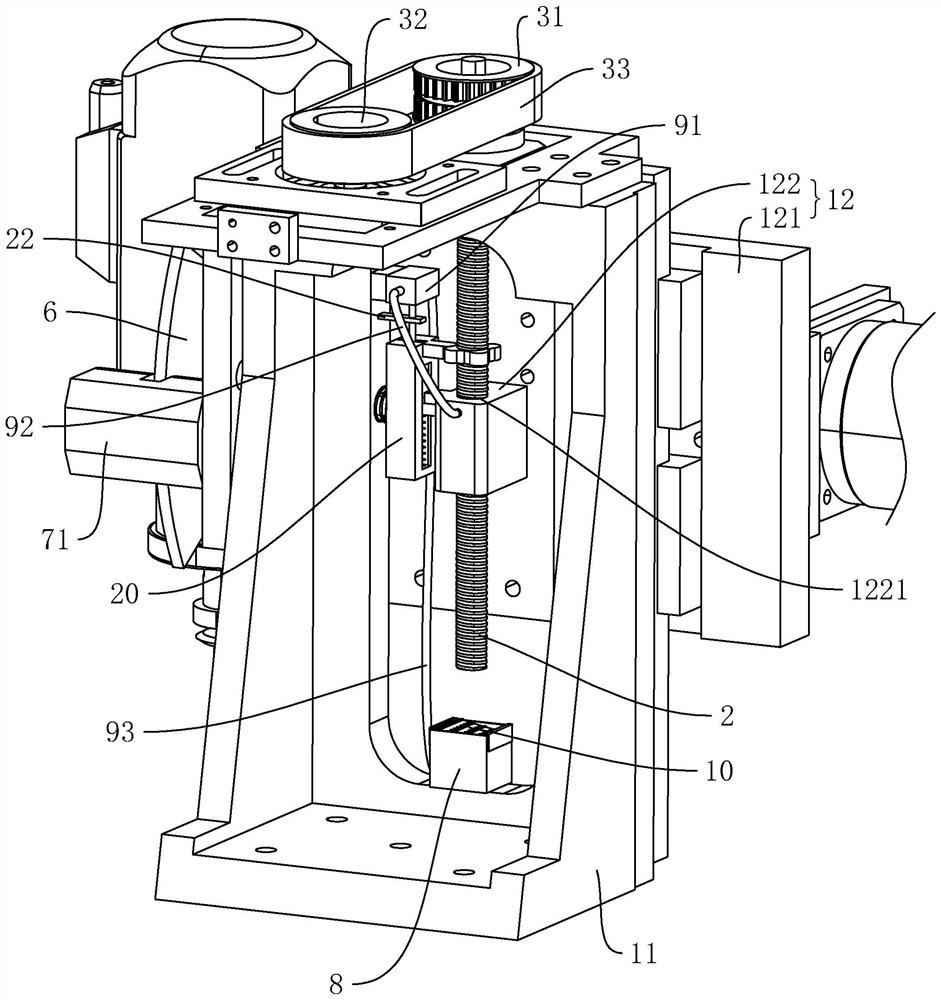

[0039] Attached to the following Figure 1-8 This application will be described in further detail.

[0040] The embodiment of the present application discloses a turntable. see figure 1 and figure 2 , the turntable includes a base 1, the base 1 includes a seat body 11 and a sliding seat 12, the seat body 11 is used to install on the machine tool, the sliding seat 12 includes a sliding part 121 and a protruding part 122, and the sliding part 121 is sleeved on the seat body The outer side of 11 is attached to the outer side wall of the base body 11 , and the sliding portion 121 lifts and slides on the base body 11 .

[0041] see figure 2 and image 3 , the penetration part 122 is provided with a perforation 1221, the perforation 1221 penetrates through the penetration part 122 vertically, the seat body 11 is rotatably connected with a screw rod 2, the rotation axis of the screw rod 2 is vertically arranged, and the screw rod 2 is vertical The sliding portion 121 moves up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com