Method for improving flavor of hotpot condiment

A hot pot base material and flavor technology, applied in the field of food processing, can solve the problems of slow flavor of spices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

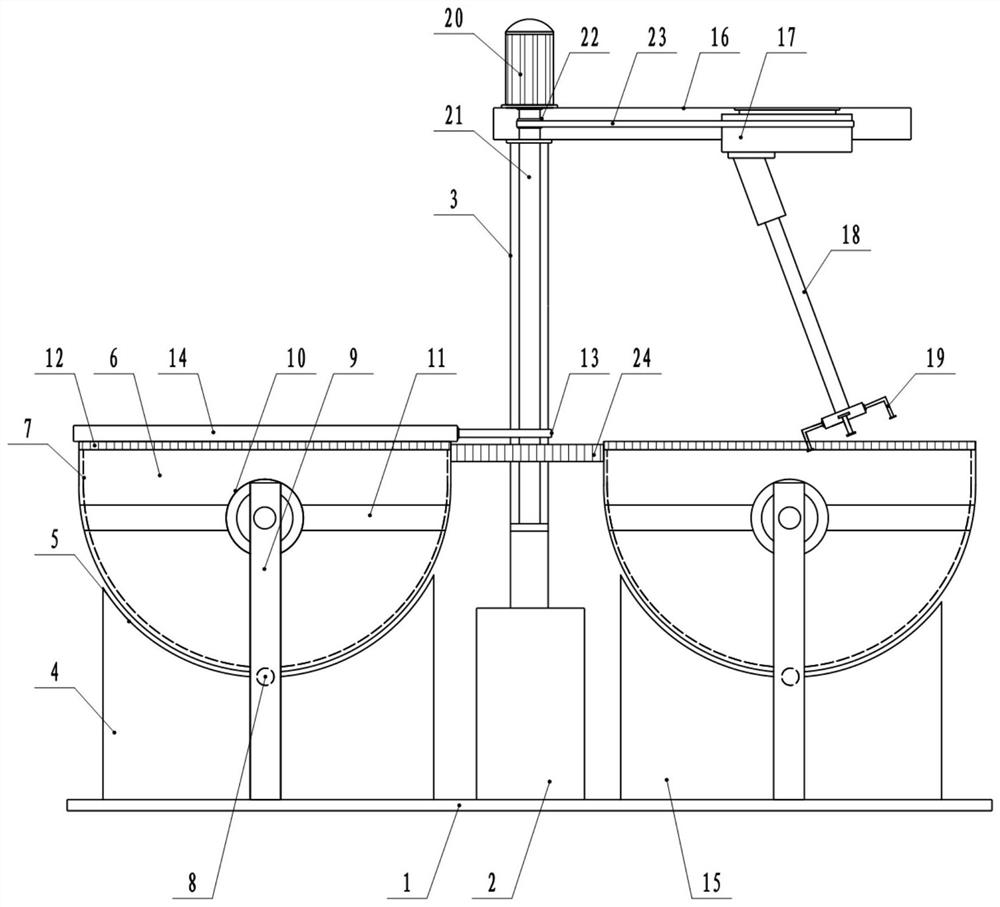

Image

Examples

Embodiment 1

[0026] A method for improving the local flavor of chafing dish, comprising the steps of:

[0027] S1: Ingredients, raw materials for hot pot base include 27-28 parts of butter, 5-5.5 parts of vegetable oil, 15 parts of shortening, 10-11 parts of Ziba chili, 3.5-4 parts of bean paste, 1.7-2 parts of soybean mother and child, 0.27-0.3 parts of Zanthoxylum bungeanum, 8-9 parts of ginger and spring onion, 0.4-0.5 parts of clove, patchouli, cinnamon bark, star anise, fragrant fruit, three Nye, Angelica dahurica, Amomum, Tsaoguo, white cardamom, and Gansong;

[0028] S2: raw material pretreatment, clove, patchouli, cinnamon, star anise, xiangguo, three Nye are crushed to a particle size of 10 mesh;

[0029] S3: Soaking, the soaking solvent is water, 55° liquor or oil, which can be selected by oneself in actual application, the ratio of solvent to spice is 2:1, the soaking temperature is 40-50 degrees Celsius, and the soaking time is 2-3 hours;

[0030] S4: Stir-fry the ingredients,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com