An automatic forging device

A forging molding, No. 1 technology, applied in the driving device of the hammer, the forging/pressing/hammer device, the driving device of the forging press, etc., can solve the problem of manual clamping and turning of workers, and reduce labor intensity and reduce costs. The effect of investing and reducing the number of placements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

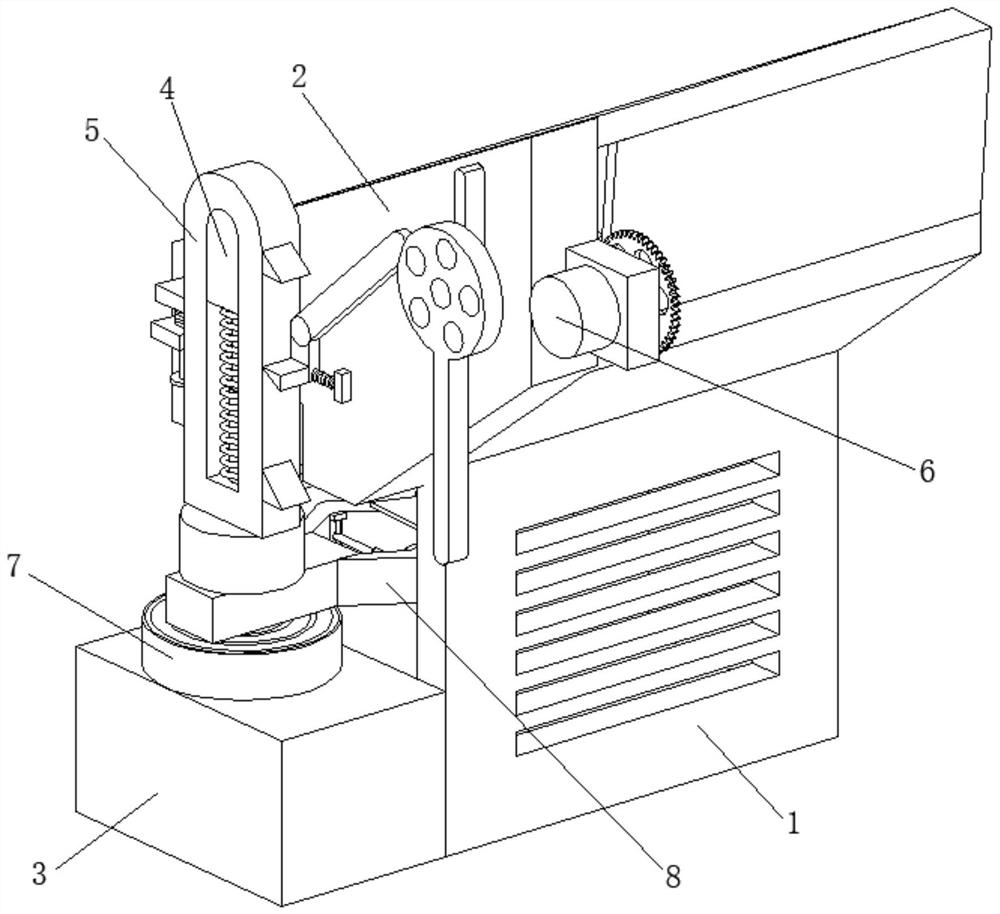

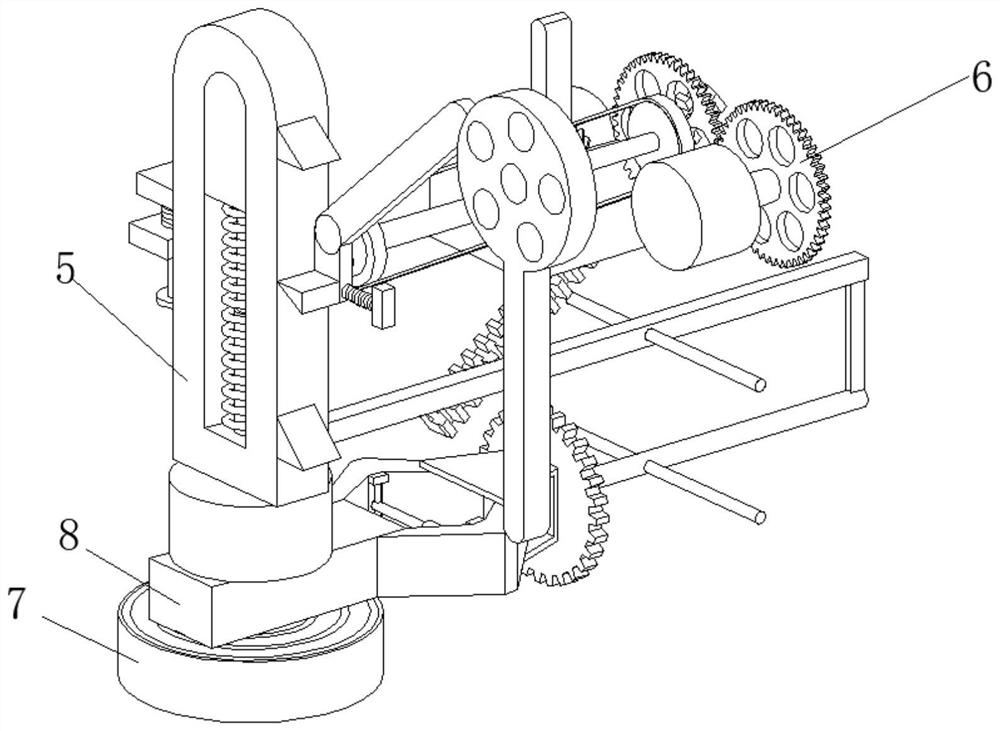

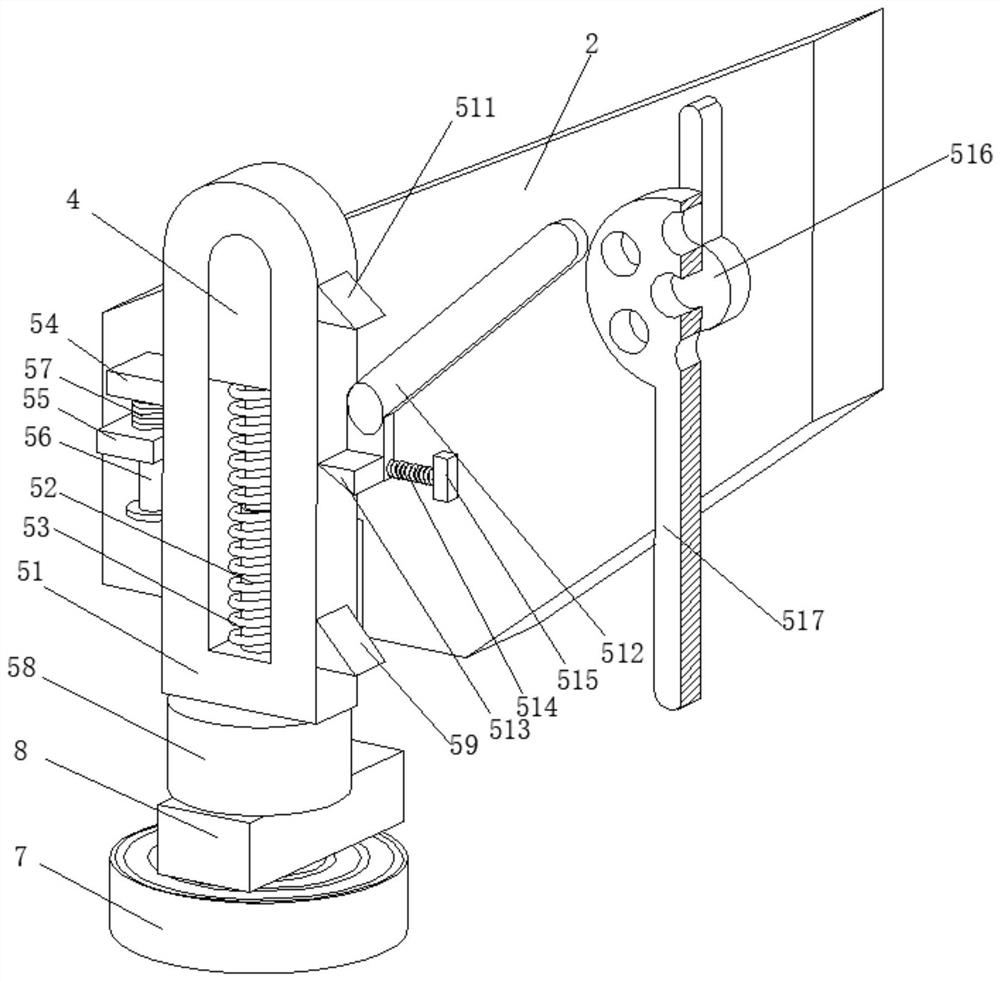

[0032] An automatic forging and forming device, such as Figure 1-Figure 7 As shown, it includes a box body 1, the front part of the box body 1 is welded with a mounting plate 2 and a support box 3, and the mounting plate 2 is located above the support box 3, and the front part of the mounting plate 2 is welded with a limit block 4, the limit The surface of the block 4 is provided with a forging mechanism 5, the right side of the mounting plate 2 is provided with a transmission mechanism 6, the top of the support box 3 is connected with a placing plate 7 by bolts, and a clamping mechanism 8 is provided on the top of the placing plate 7.

[0033]In this embodiment, the forging mechanism 5 includes a sliding block 51 , a telescopic column 52 is welded on the inner wall of the sliding block 51 , a support spring 53 is sleeved on the surface of the telescopic column 52 , and a stopper 54 is welded on the left side of the sliding block 51 . The front part of the plate 2 is welded w...

Embodiment 2

[0039] like Figure 7-Figure 9 As shown, the inner wall of the No. 1 chuck 661 is slidably connected to the surface of the rotating shaft 67, the front end of the contraction spring 662 is welded and fixed to the rear end of the limit plate 663, and the contraction spring 662 can pull the No. 1 card after the inclined plate 664 moves down The disk 661 is reset, so that the No. 1 chuck 661 can be separated from the No. 2 chuck 665, so that the rotating shaft 67 can move intermittently, so that the steel will not rotate during forging, preventing it from interfering with the hammer head 58, resulting in Damage to the device increases maintenance costs and reduces usability.

[0040] It is worth noting that the clamping mechanism 8 includes a mounting block 81 , two clamping blocks 82 are rotatably connected to the inner wall of the mounting block 81 , an oil cylinder 83 is movably connected between the two clamping blocks 82 , and the two clamping blocks 82 are in contact with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com