Oil pumping system for crankshaft and compressor with same

A compressor and pump oil technology, applied in the field of compressors, can solve problems such as large friction power consumption, and achieve the effects of improving operational reliability, reducing friction power consumption, and reducing radial spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

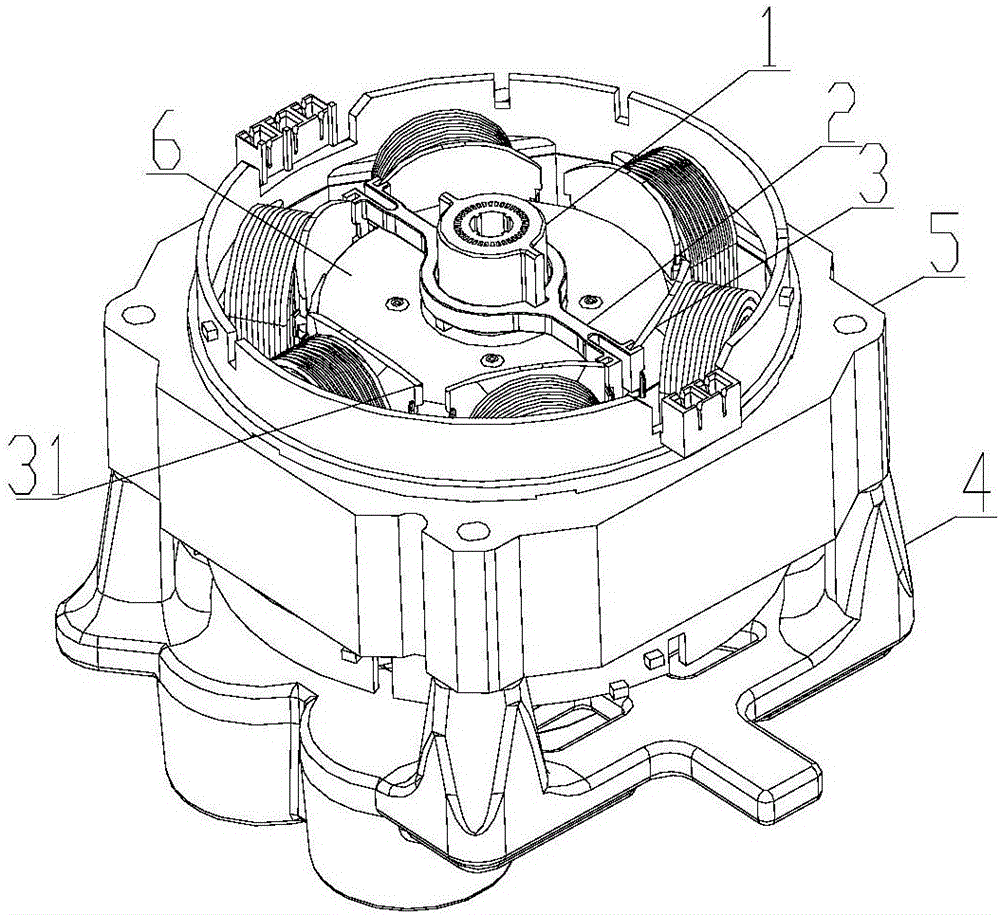

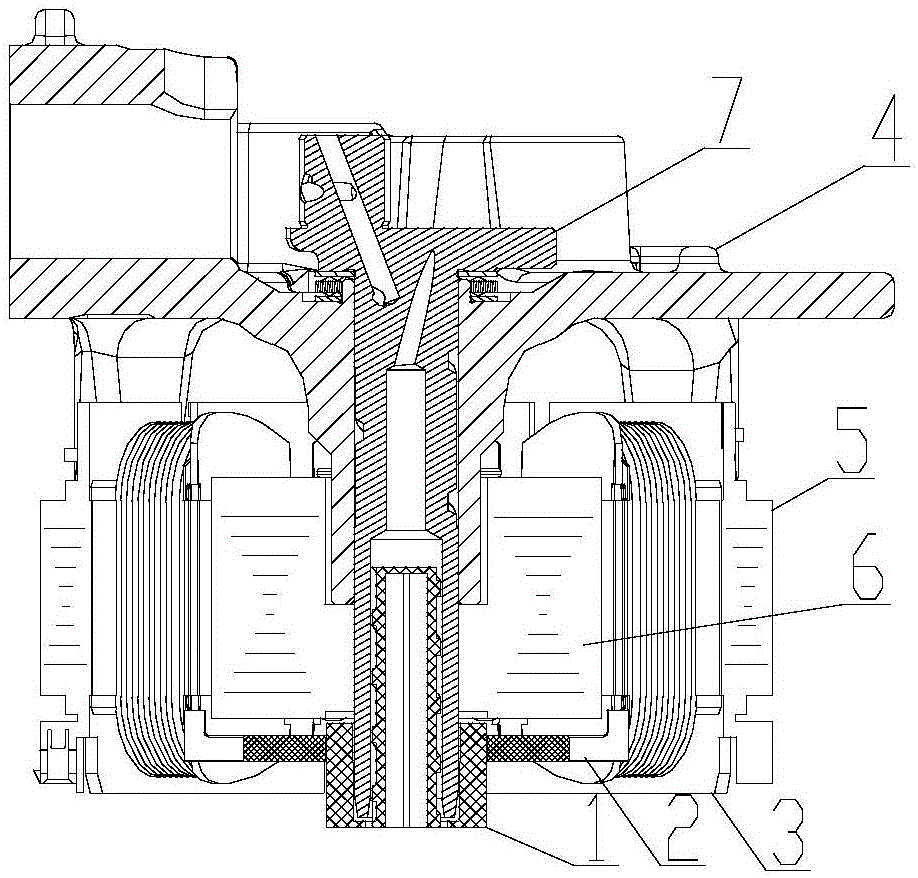

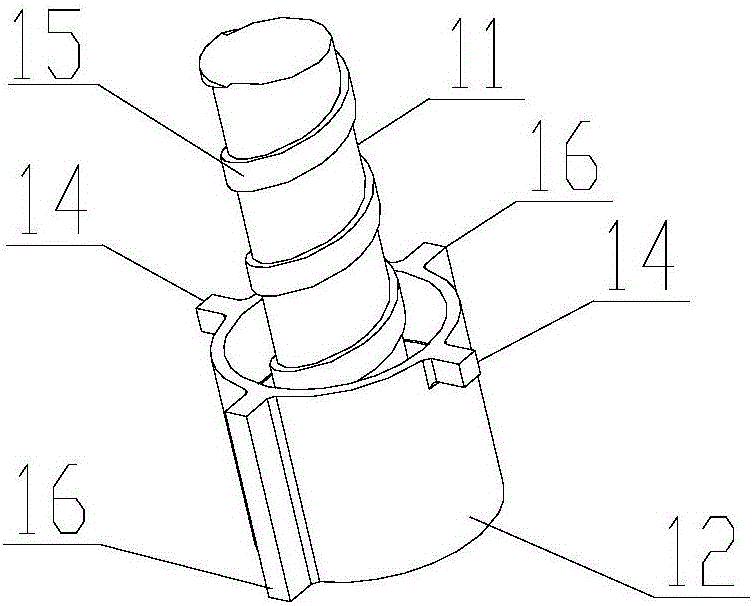

[0080] The oil pumping system of a fully enclosed piston compressor generally includes a cylinder block 4, a motor stator 5, a motor rotor 6, a stator insulating frame 3, an oil pump bracket 2, a crankshaft 7, an oil pump 1, and an oil pool at the bottom of the housing. The crankshaft 7 is inserted into the shaft hole of the cylinder block 4, the motor rotor 6 is interference-fitted on the crankshaft outer surface 71, the motor stator 5 is fixed on the cylinder block 4 by screws, and the crankshaft can rotate under the action of the motor. The screw pump core 11 of the oil pump 1 is inserted into the oil hole 72 at the bottom of the crankshaft, the inner wall of the cylindrical outer casing 12 is set on the outer surface 71 of the crankshaft, the center hole of the oil pump bracket 2 is installed on the periphery of the oil pump 1, and the center hole limit groove 23 is connected with the anti-rotation limit protrusion. The bar 16 cooperates to ensure that the oil pump 1 does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com