Flexible element

A spring unit, vehicle technology, applied in the direction of vehicle springs, vehicle components, springs/shock absorbers, etc., can solve the problems of reducing the bearing surface area of the end plate, space constraints, and difficult installation of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

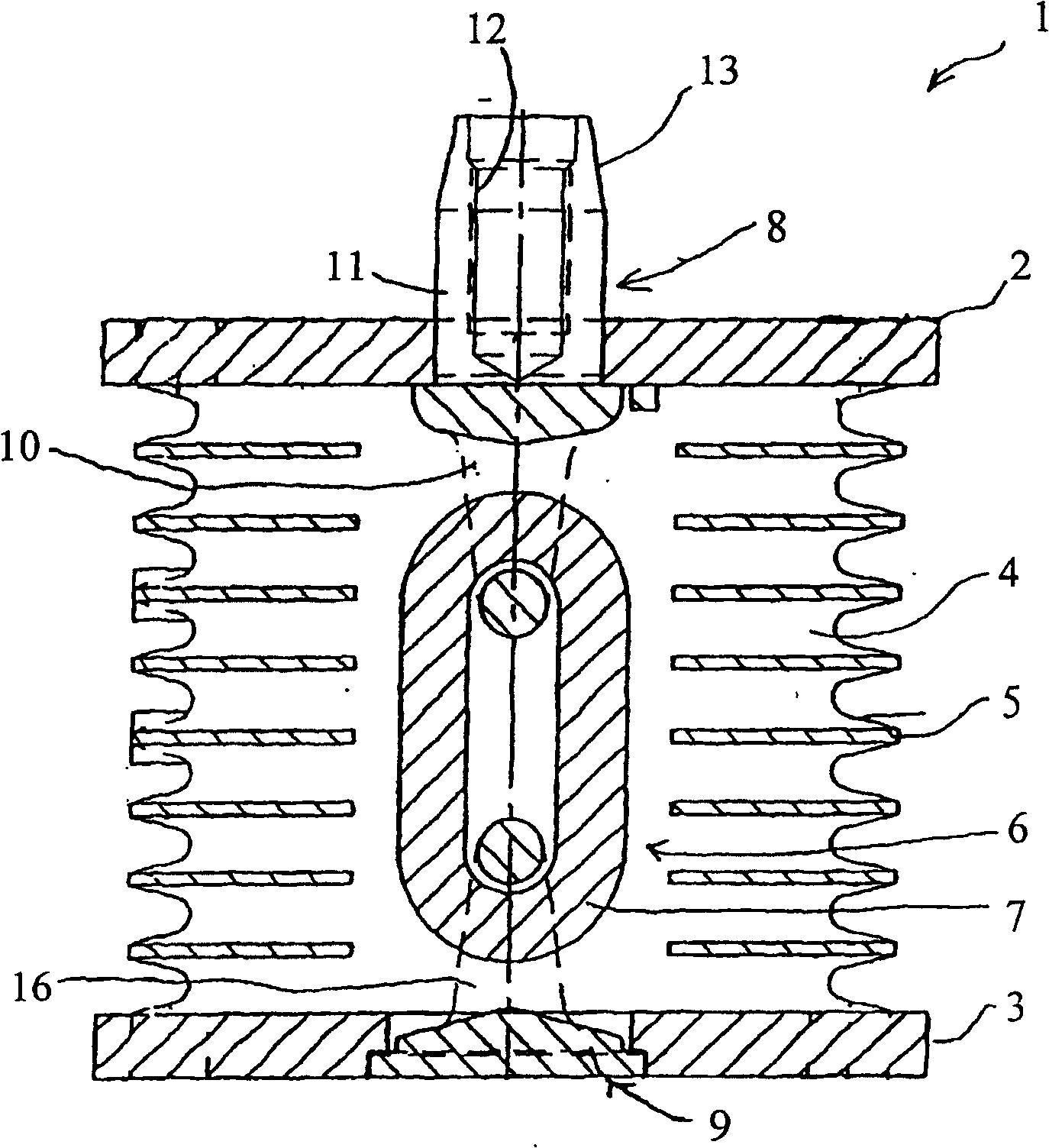

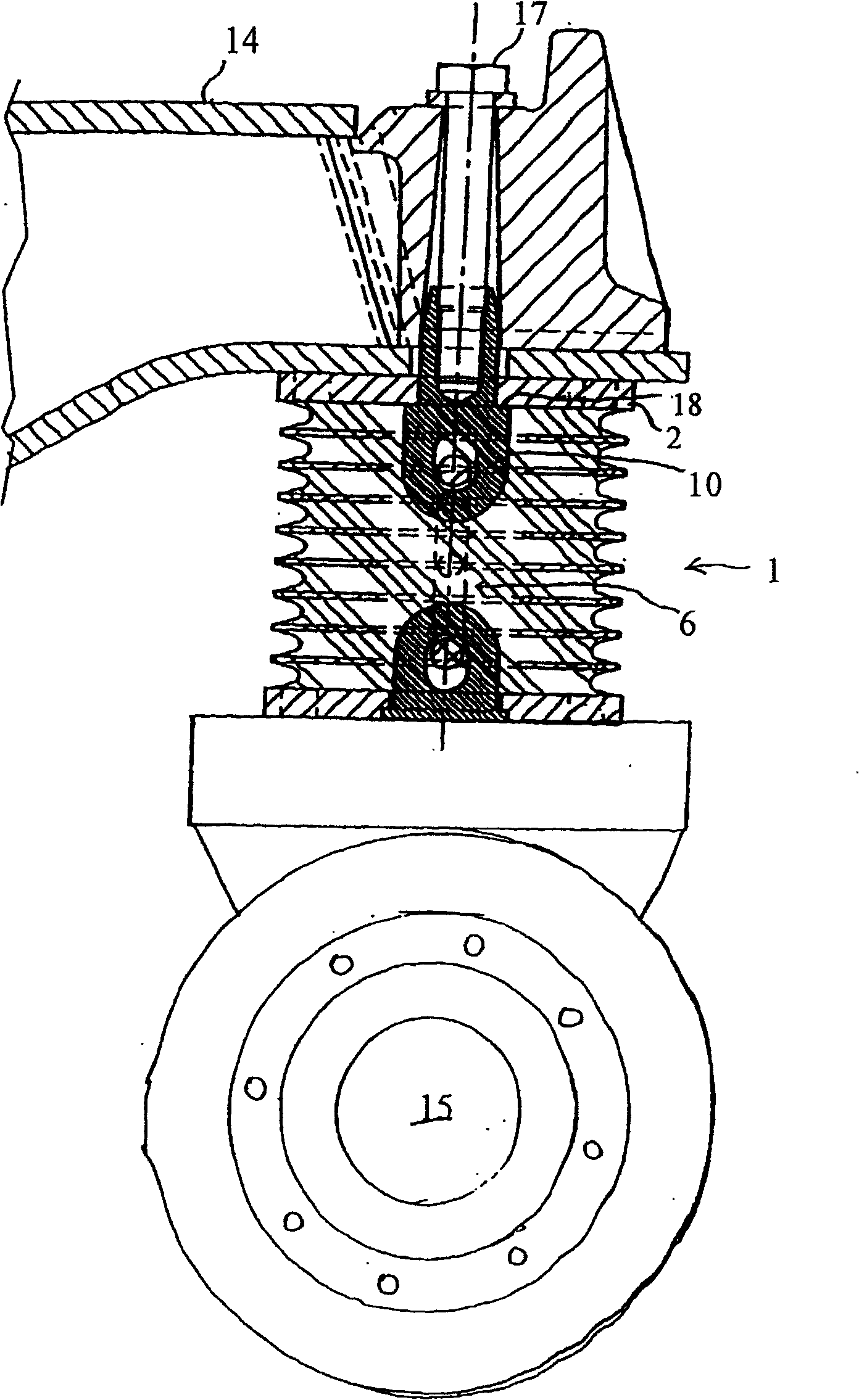

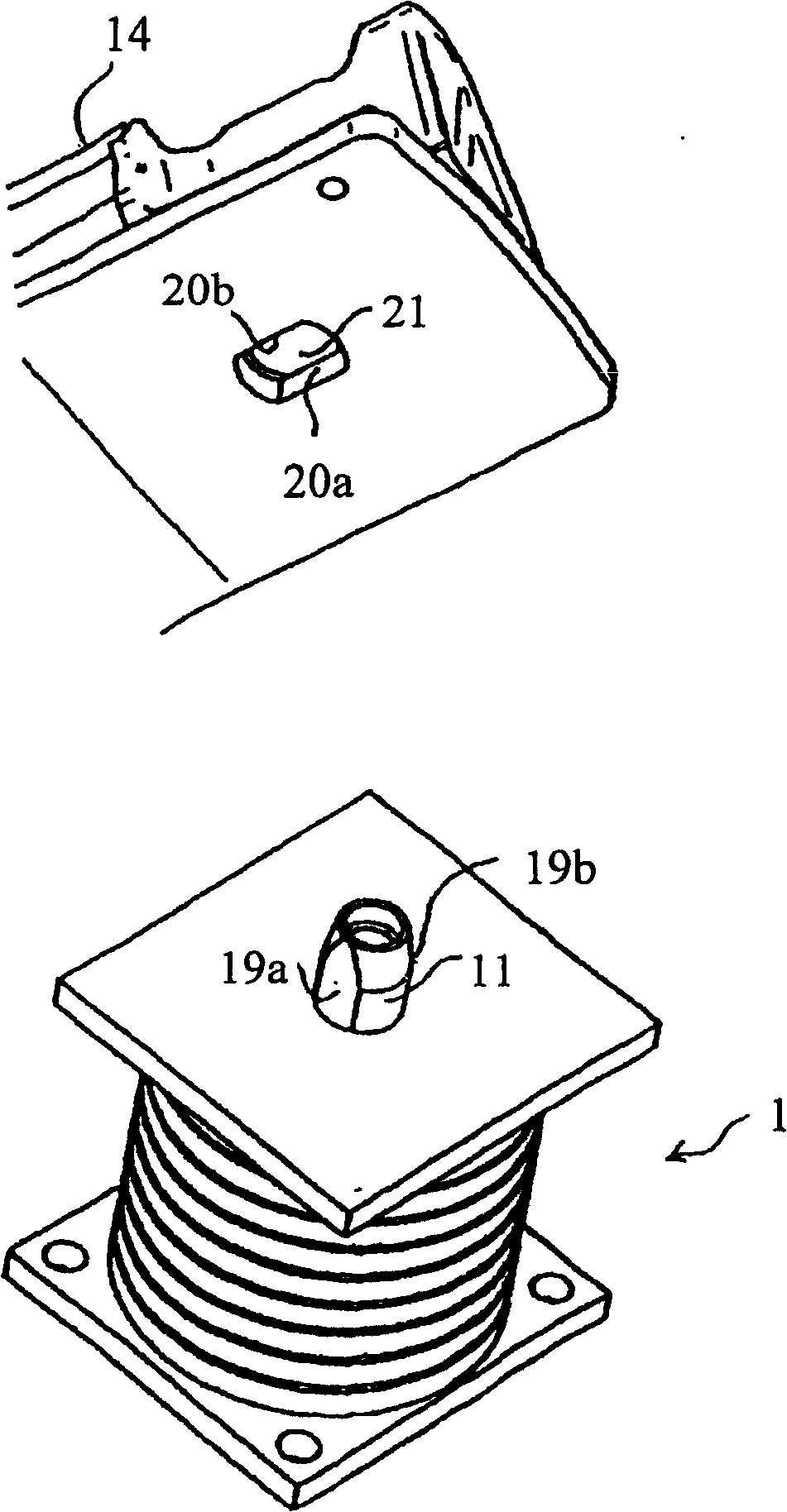

[0017] figure 1 A schematic diagram of a first embodiment of a spring unit 1 according to the invention is shown. The spring unit 1 comprises a first end plate 2 and a second end plate 3 which are substantially parallel when the spring unit 1 is empty. Between the end plates 2, 3 there is a vulcanized solid cylindrical rubber body 4, in a manner known per se, by using a plurality of parallel and separated flat metal rings 5 to resist the outward movement of the rubber body 4 during compression Expand to strengthen the rubber body.

[0018] The end plates 2, 3 are held together by the use of a mechanical connection 6 comprising an endless chain connection 7 which connects the rubber body 4 protruding from the central part of the respective end plates 2, 3 into the rubber body 4. The first coupling mechanism 8 and the second coupling mechanism 9.

[0019] On the one hand, the first coupling mechanism 8 has a U-shaped connecting unit 10, which extends into the rubber body 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com