Auxiliary device and method for detecting rust resistance of reinforcing steel bar under pure bending

An auxiliary device, pure bending technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, and the use of stable torsion to test the strength of materials, etc. There are no reported problems such as corrosion performance, to avoid stress measurement errors, good practicability, and avoid complex stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

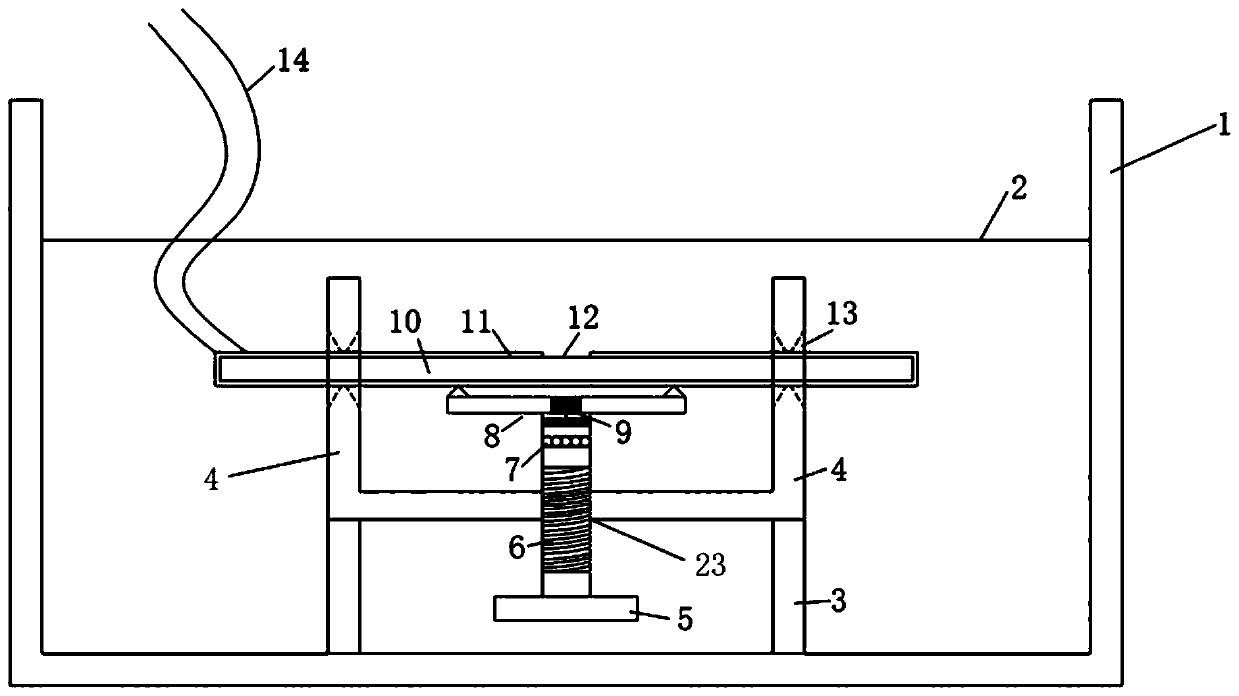

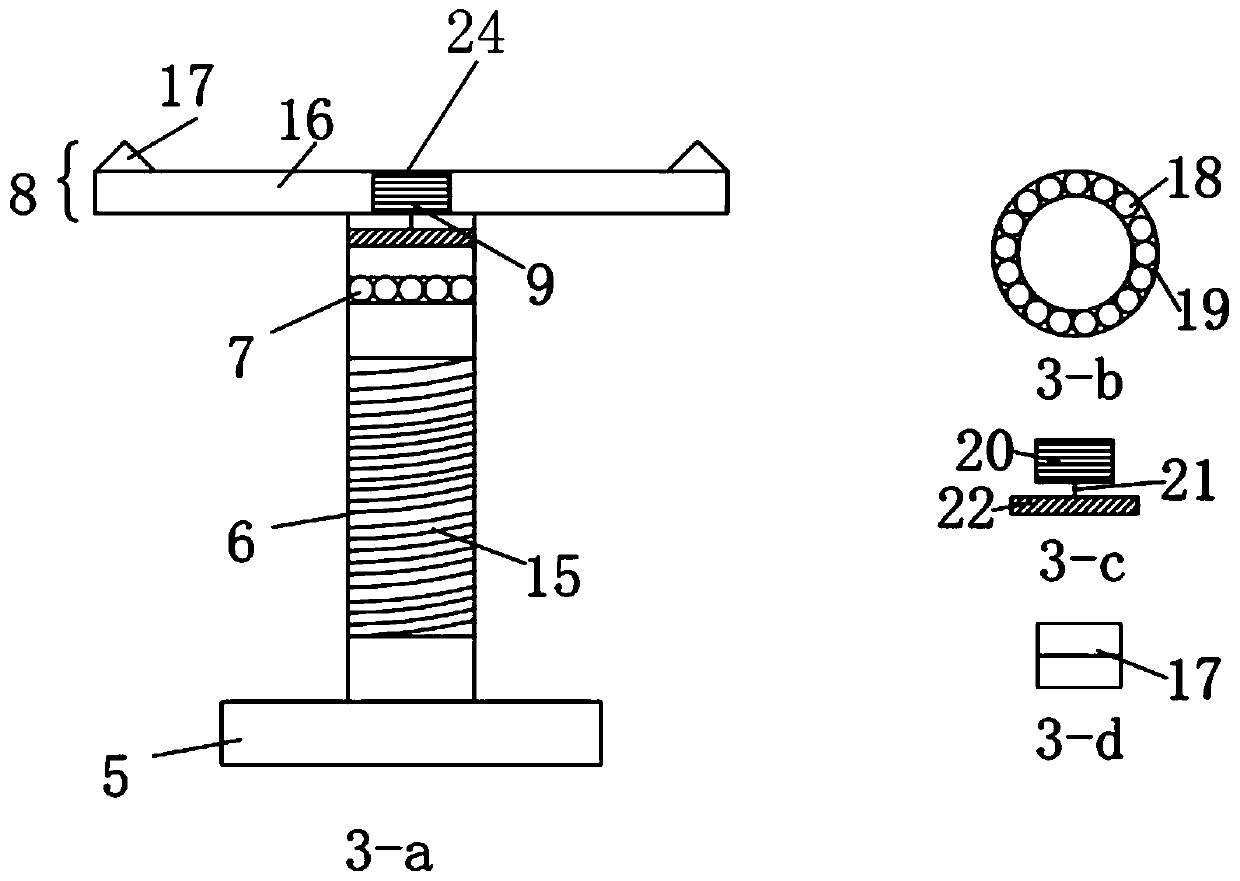

[0027] An auxiliary device for detecting the corrosion resistance of steel bars under pure bending, such as figure 1 As shown, it includes a container 1 and a loading device fixed in the container 1. The loading device includes a fixed base 3, a loading knob 5, a spiral vertical strut 6, a ball-type torque eliminator 7, an embedded liquid crystal display force measurement 9, loading part 8 and loading slot 4. The container 1 is filled with an erosion simulating liquid 2 , and the loading device is immersed in the erosion simulating liquid 2 .

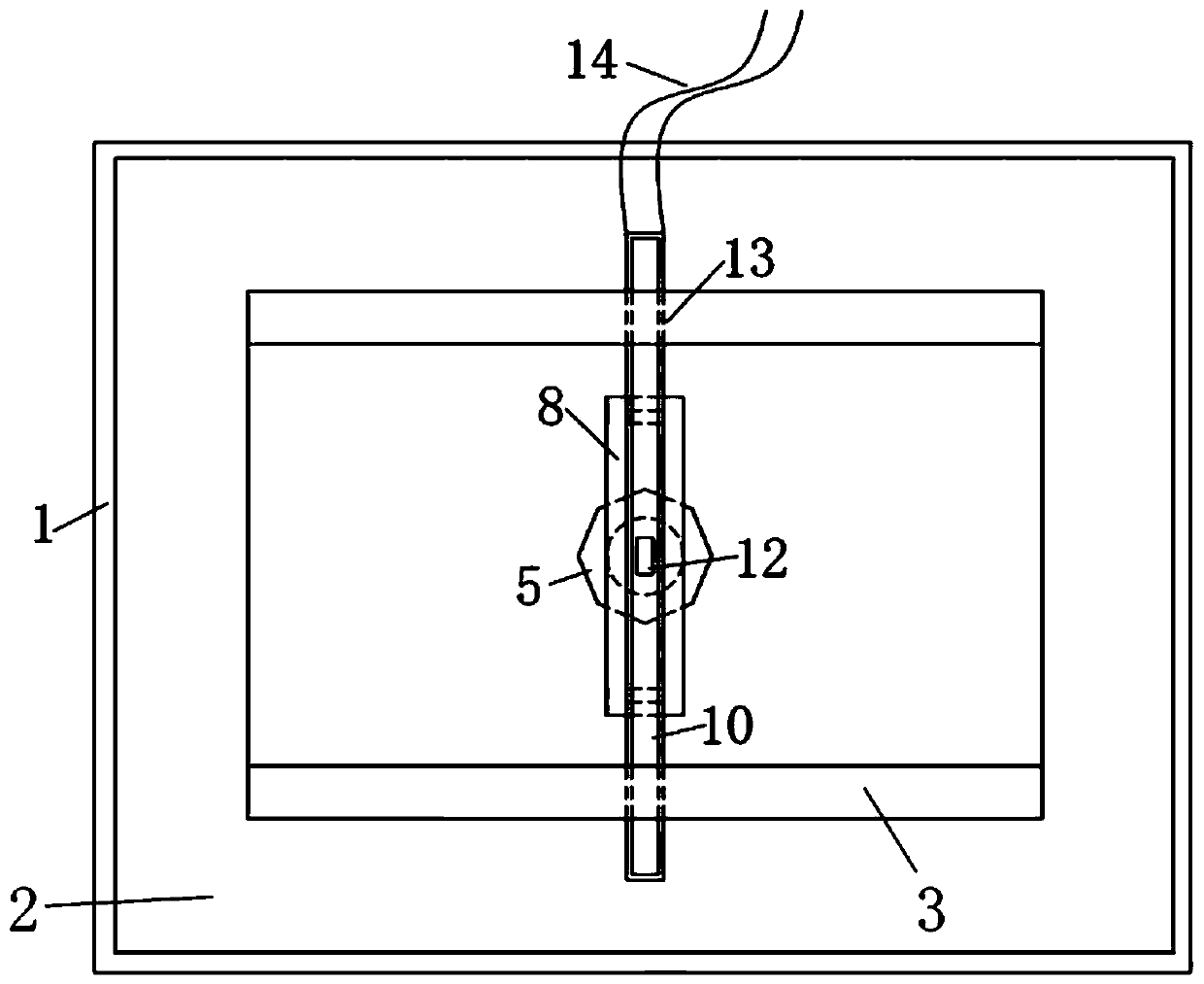

[0028] like figure 2 As shown, the fixed base 3 is a strip-shaped structure and is located on both sides of the bottom of the container 1, so that the loading device can be kept stable in the erosion simulation liquid 2, that is, it is used to fix the loading device.

[0029] like figure 1 As shown, the fixed base 3 is provided with a loading slot 4 , the wall of the loading slot 4 is provided with a specimen fixing jaw 13 , and the...

Embodiment 2

[0036] A method for detecting the corrosion resistance of steel bars under pure bending, the specific steps are as follows:

[0037] (1) Handling of specimens: such as figure 1 As shown, the surface of the test piece 10 is wrapped with a layer of epoxy resin, and then closed with a soft adhesive layer to form a sealing coating 11, and an exposed area 12 is provided in the middle of the test piece 10, and the length of the exposed area 12 is 1~ 1.5 cm in width and 0.8-1 cm in width; one end of the test piece 10 is welded with an enameled wire 14 , and the exposed metal part of the enameled wire 14 is wrapped in the sealing coating 11 .

[0038] (2) Loading load: Fix the processed specimen 10 at the specimen fixing jaw 13 of the loading tank 4, and then rotate the loading knob 5 to drive the spiral vertical support rod 6 to move upward, so that the two The force-bearing tip 17 touches the test piece 10 above it, and continues to rotate to give a load to the test piece 10. The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com