Grinding machine crankshaft machining counter weight device

A technology for crankshaft processing and counterweight device, which is applied in grinding machines, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc. Easy to install and easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

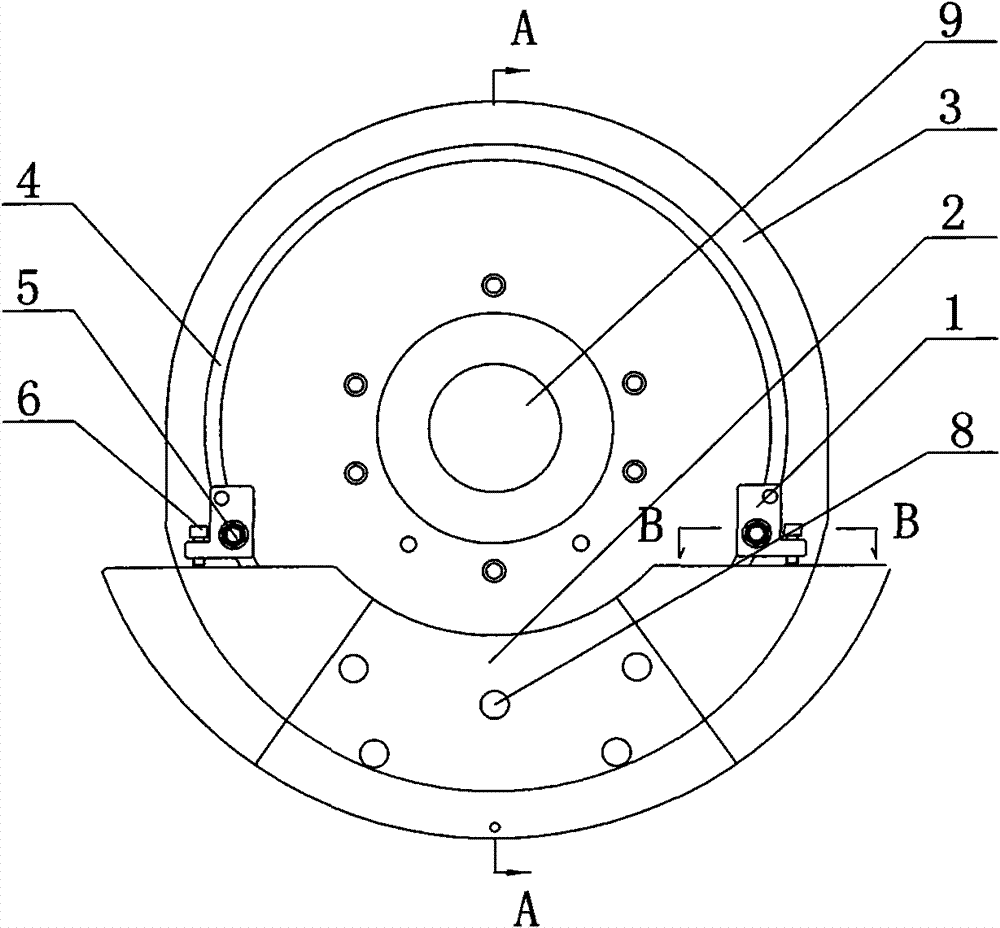

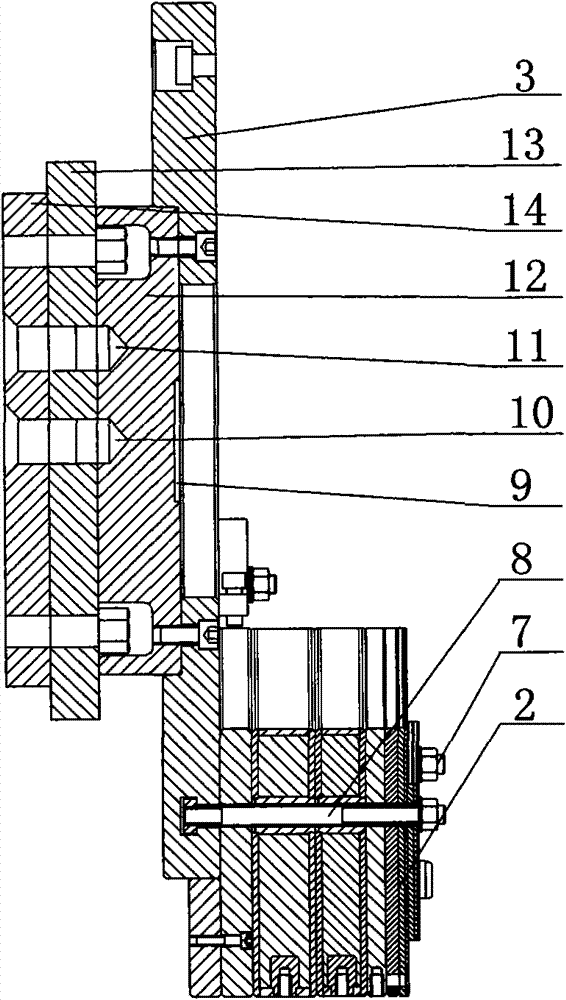

[0023] The present invention comprises centering top plate 13, and the side of centering top plate 13 is provided with eccentric mounting plate 12, eccentric balance plate 3 in sequence, and the outer side of one end of eccentric balance plate 3 is provided with arc-shaped counterweight balance plate 2, and the arc-shaped counterweight balance plate 2 is The heavy balance plate 2 is fixed on the eccentric balance plate 3 through bolts 8 and nuts 7 on the eccentric balance plate 3 .

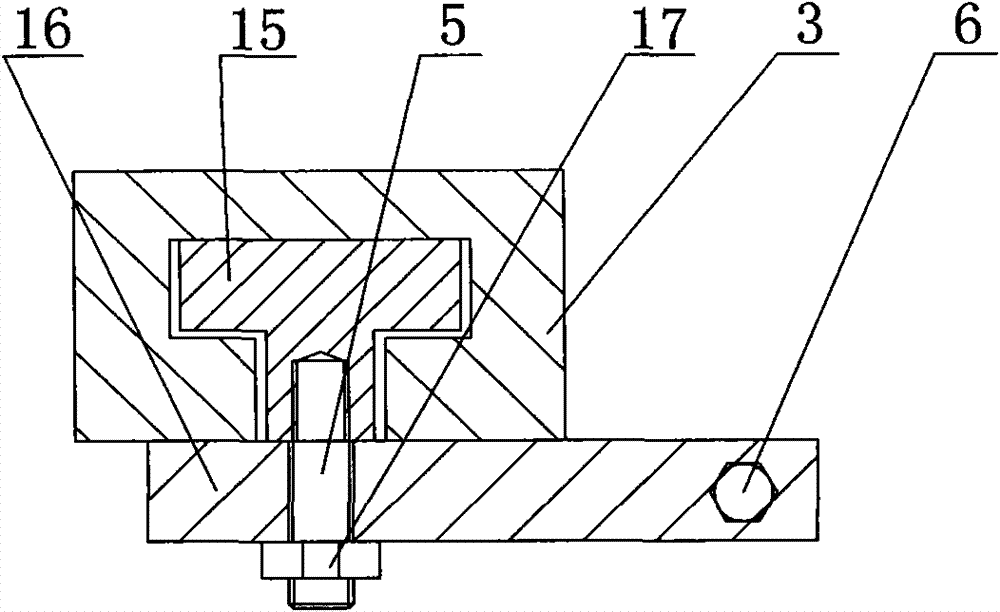

[0024] On both sides of the eccentric balance plate 3 above the arc-shaped counterweight balance plate 2, a fine-tuning mechanism 1 is respectively arranged; the fine-tuning mechanism 1 includes an arc-shaped groove 4 on the eccentric balance plate 3, and the cross-section of the arc-shaped groove 4 is T-shaped. The T-shaped block 15 in the arc groove 4 is provided with an adjusting bolt 5, and the baffle plate 16 is fixed between the compression nut 17 of the adjusting bolt 5 and the eccentric bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com