Alloy apparatus adjustable in clamping angle

An angle and alloy technology, used in metal processing machinery parts, clamping, metal processing equipment and other directions, can solve the problems of loose workpiece, low precision of processed parts, slow processing speed, etc., to achieve convenient long-distance automatic control, improve The effect of force structure and function diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

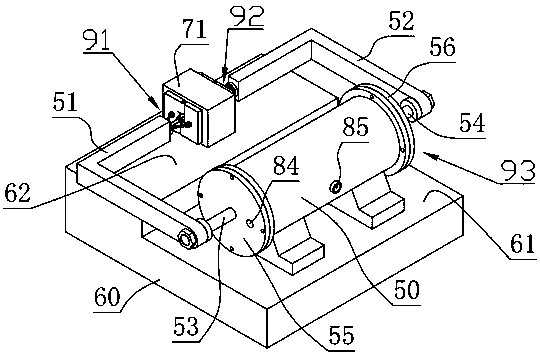

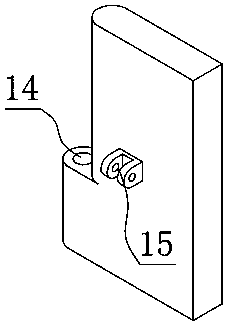

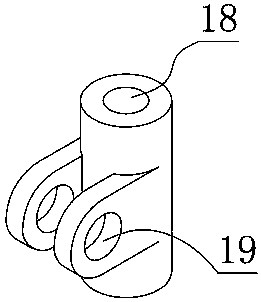

[0045] In the picture:

[0046] The first splint-10, the first swing hole-11, the first support hole seat-12, the second splint 13, the second swing hole-14, the second support hole seat 15, the angle pin-16, the support Sleeve-17, sleeve shaft hole-18, sleeve hole seat-19, first swivel base-20, swivel base shaft hole-21, swivel base swing hole-22, second swivel base-23, first Connecting rod-24, second connecting rod-25, hole seat sliding sleeve-26, left connecting rod hole seat-27, right connecting rod hole seat-28, hole seat sleeve inner hole-29, adjusting nut-30, nut Shaft shoulder section-31, nut cylindrical section-32, nut square shaft section-33, nut outer thread section-34, internal thread hole-35, lock nut-39, adjusting screw-40, adjusting hand wheel-41, Positioning nut-42, screw sleeve shaft pin-44, screw swing hole-47, hand wheel square hole-48, hydraulic cylinder-50, left support arm-51, right support arm-52, first piston- 53. The second piston-54, the first end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com