Cutting type multi-angle adjusting separating forceps for laparoscopic surgery

A surgical, multi-angle technology, applied in the direction of laparoscopy, surgical forceps, application, etc., can solve problems such as organ separation and other operations are limited, and the clamping part of the separation forceps cannot be adjusted in direction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

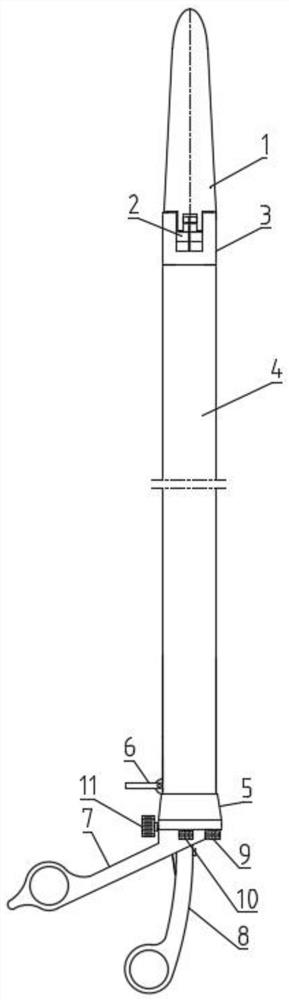

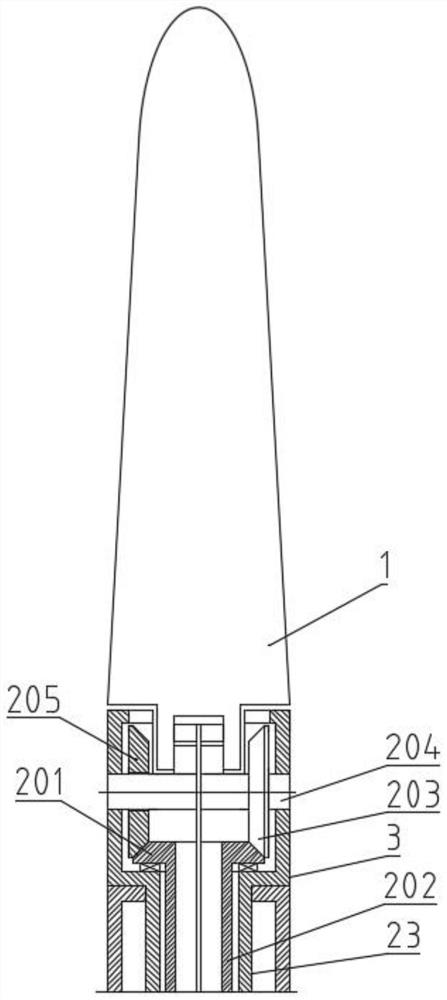

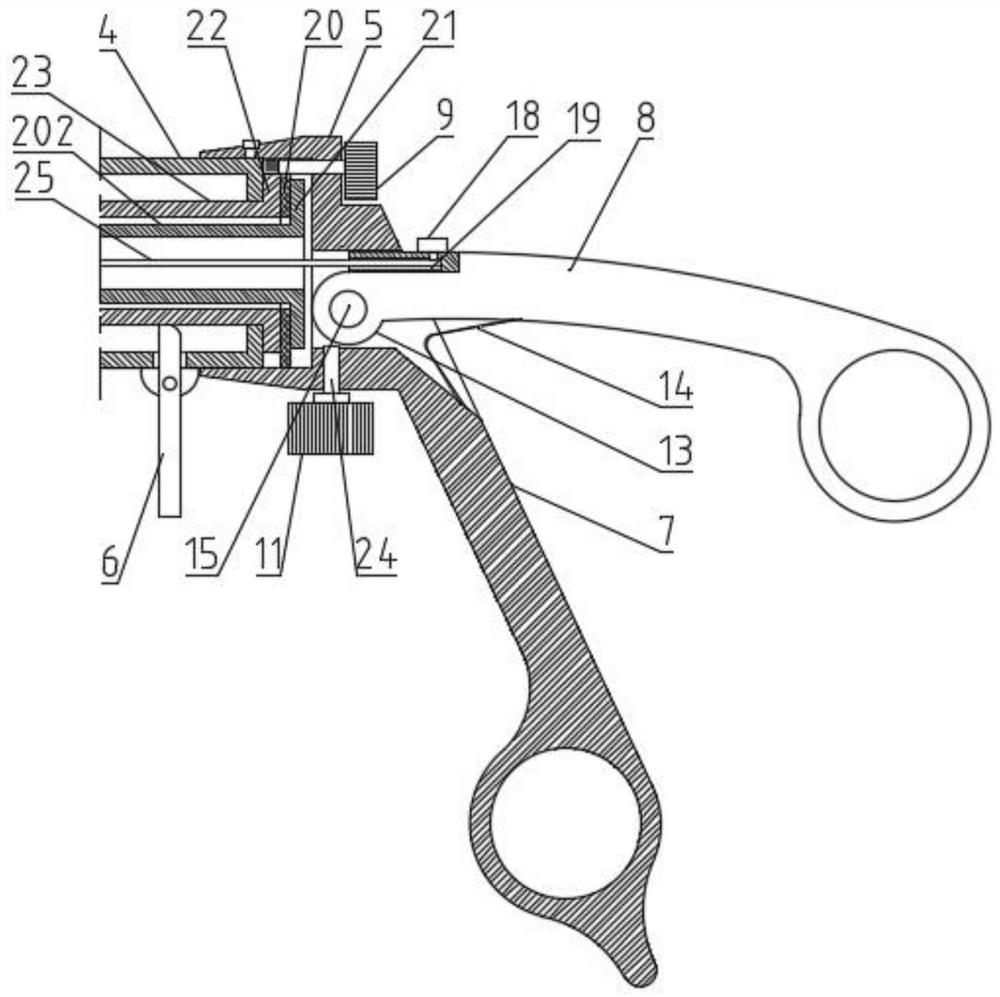

[0052] Such as Figure 1-11 As shown, a scissors type laparoscopic surgery with multi-angle adjustment separation forceps, comprising a rod body 4, the front end of the rod body 4 is provided with a swivel seat 3, the swivel seat 3 is provided with a turning mechanism 2; the turning mechanism 2 A clamping part 1 is arranged on it; the tail end of the rod body 4 is connected to an end seat 5; a first joystick 7 and a second joystick 8 for controlling the opening and closing of the clamping part 1 are arranged on the end seat 5; The end surface of the end seat 5 is provided with a rotary knob 9 for controlling the rotation of the rotary seat 3 and a turning knob 10 for controlling the flipping of the clamping part 1; the tail end of the rotary seat 3 is connected to a rotary rod 23; the rotary rod 23 passes through The rod body 4 is connected with the second toothed disc 22 behind; the pinion 17 coaxially connected with the rotary knob 9 meshes with the second toothed disc 22; t...

Embodiment 2

[0055] Such as image 3 As shown, as a further optimization of the above embodiment: the front end of the second joystick 8 is provided with a turntable body 13; the turntable body 13 is provided with an installation hole, and the installation hole is sleeved on the installation shaft 15 of the first joystick 7 ; The end seat 5 is provided with a positioning knob 11 ; The turntable body 13 and the second joystick 8 are of an integrated structure, and the mounting holes are coaxially arranged on the turntable body 13; the outer wall of the turntable body 13 can be provided with a non-slip surface; the positioning knob 11 is connected to the screw rod 24, and when the positioning knob 11 is rotated, The screw rod 24 can bear against the turntable body 13, thereby preventing the second joystick 8 from swinging.

Embodiment 3

[0057] Such as image 3 As shown, as a further optimization of the above embodiment: the side of the rod body 4 is connected to the control rod 6 through a hinge shaft, and the front end of the control rod 6 extends into the rod body 4 to withstand the rotating rod 23 . The control rod 6 is short rod-shaped, and the hinge shaft is arranged at the upper end position of the middle section of the control rod 6; anti-slip lines can be set on the outer wall of the rotating rod 23, and the upper end of the control rod 6 is against the anti-slip lines, thereby preventing the rotating rod 23 from rotate. The anti-slip texture can adopt toothed texture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com