Transmission mechanism of numerical control vertical machining center

A transmission mechanism, CNC vertical technology, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problem of power equipment and transmission mechanism can not be quickly separated to stop power transmission, power equipment damage, short circuit and other problems, to achieve Easy to assemble the hole and avoid the effect of load phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

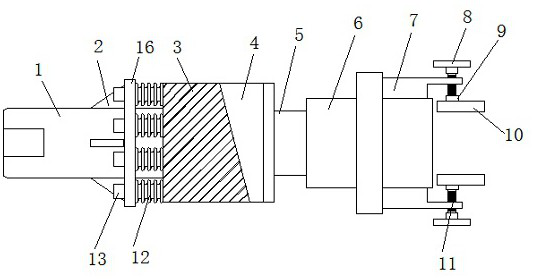

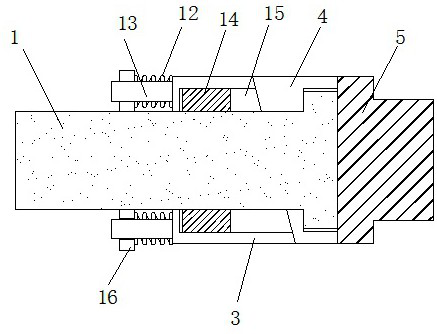

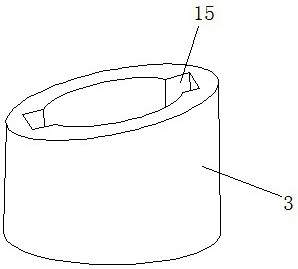

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution: a transmission mechanism of a numerically controlled vertical machining center, including a transmission shaft 1, and one end of the transmission shaft 1 is provided with a first connecting block 3 and a second connecting block 4, through the first designed The slopes of the first connecting block 3 and the second connecting block 4 are squeezed and contacted with each other, thereby ensuring synchronous rotation and realizing power transmission. At the same time, the two are assembled separately. The inclined surface produces an effect, provides thrust to the two connecting blocks, thereby realizing disengagement, stopping power transmission, and effectively avoiding the load phenomenon of the power source. The adjacent surfaces of the first connecting block 3 and the second connecting block 4 are provided with equal inclined The other end of the first connecting block 3 is provided with a...

Embodiment 2

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a transmission mechanism of a numerically controlled vertical machining center, including a transmission shaft 1, and one end of the transmission shaft 1 is provided with a first connecting block 3 and a second connecting block 4, through the first designed The slopes of the first connecting block 3 and the second connecting block 4 are squeezed and contacted with each other, thereby ensuring synchronous rotation and realizing power transmission. At the same time, the two are assembled separately. The inclined surface produces an effect, provides thrust to the two connecting blocks, thereby realizing disengagement, stopping power transmission, and effectively avoiding the load phenomenon of the power source. The adjacent surfaces of the first connecting block 3 and the second connecting block 4 are provided with equal inclined The other end of the first connecting block 3 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com