Nitridized and undercut fillet rolling and reinforcing technology of normalized nodular cast iron crankshaft

A technology of nodular cast iron and rounded corners, which is applied in metal material coating process, solid diffusion coating, coating, etc., can solve problems such as not being able to meet service conditions, avoid bearing bush edge load phenomenon, improve fatigue bending moment, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] To be strengthened is the model Y4105 ductile iron crankshaft, the material is QT800-3.

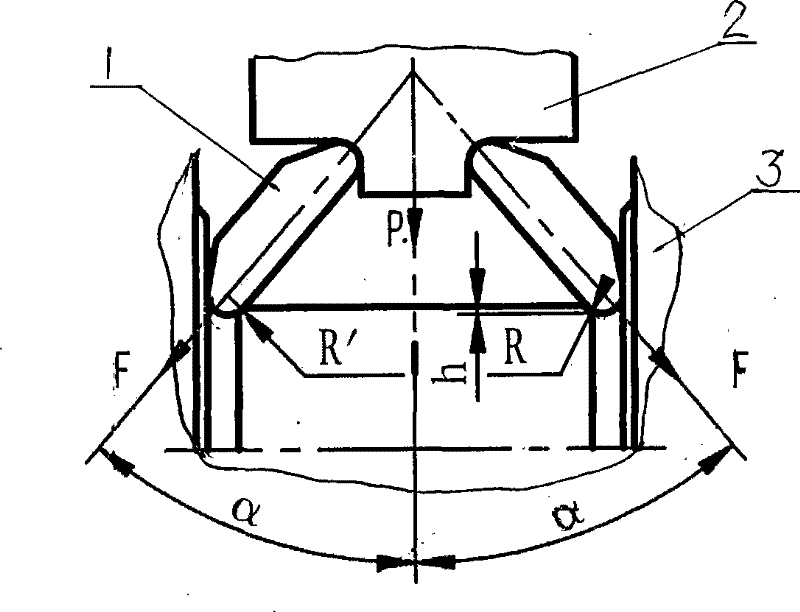

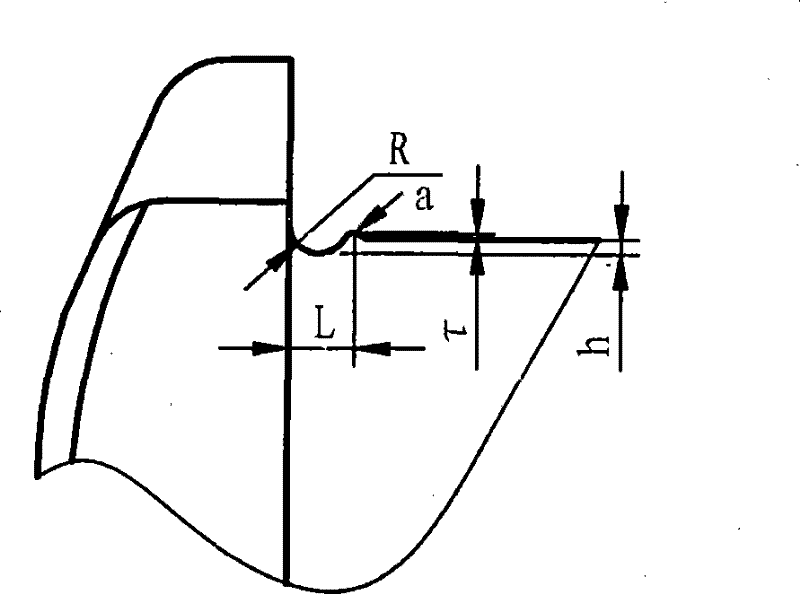

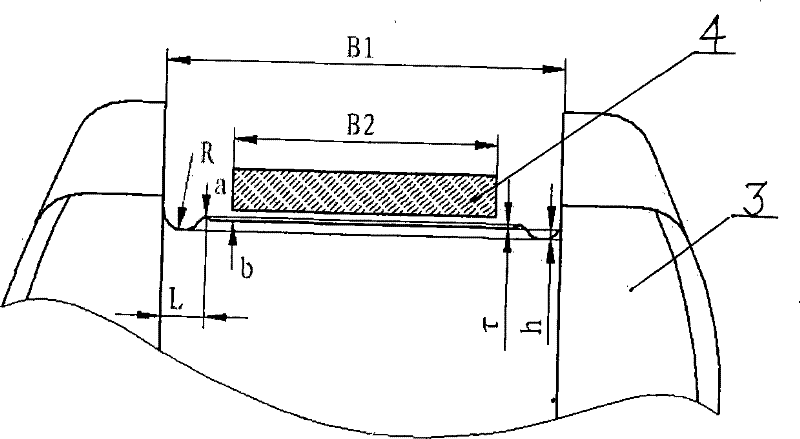

[0020] A process for nitriding and undercutting rounded corner rolling strengthening of normalized nodular cast iron crankshafts. The process is to perform rounded undercutting on the crankshaft main journal and connecting rod neck, and cut undercutting grooves at the rounded corners , and then nitriding, through the control of the nitriding furnace atmosphere, the crankshaft journal and fillet surface form a nitriding layer, in which the white and bright compound layer is 0.002-0.007mm below the outer surface, and the diffusion layer is 0.08-0.12mm below the outer surface. Surface hardness HV 0.1 600, and then use the rolling wheel to directly roll the rounded corner after sinking. When rolling, the rolling angle α is 40°, the rolling force P is 11000N, and the rolling radius R is 1.9mm. The pressing depth h is 0.4mm, and the radius R' of the undercut groove is 2.2.

[0021] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com