Design method of TBCC exhaust nozzle adjusting mechanism based on double-shifting-piece type sliding block principle

A double paddle type and design method technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of aggravated flow loss, etc., and achieve the effects of reducing gas flow loss, reducing space occupation, and saving thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention is further described below by way of specific embodiments.

[0026] The present invention provides a nozzle adjustment mechanism based on two tail TBCC paddle type slider principle, for the purposes of this invention, the design and the effect is more clear and unambiguous, the drawings of the present invention will be further described in detail. It should be understood that the specific embodiments described herein are merely content to explain the present invention but are not intended to limit the present invention.

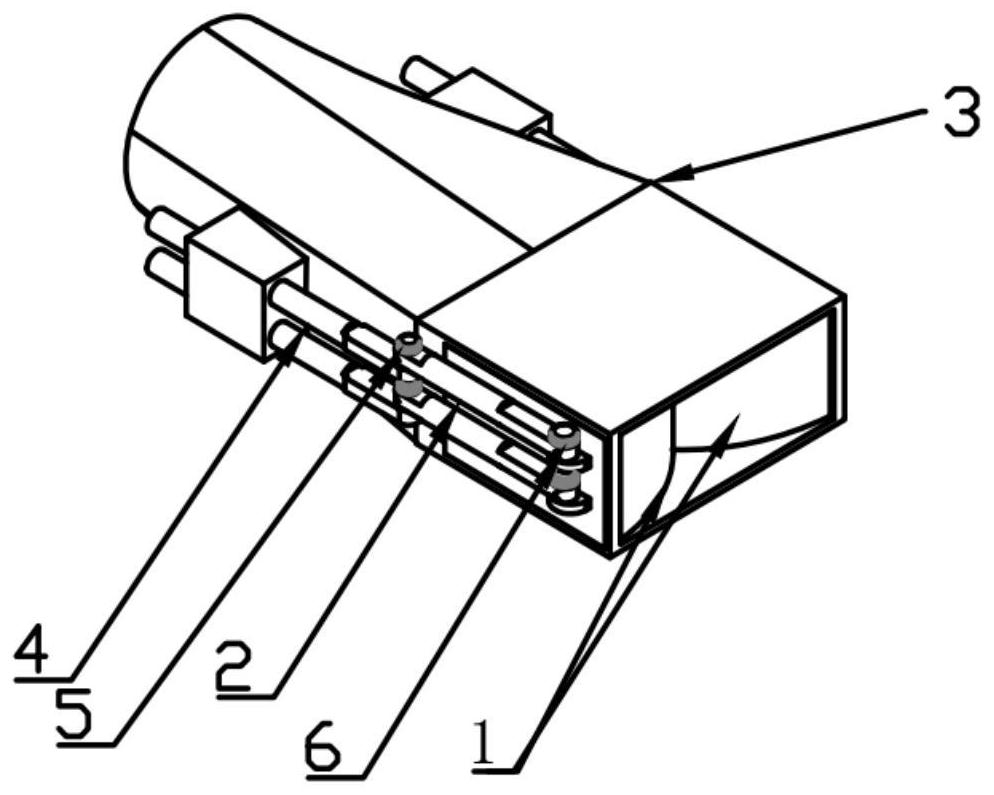

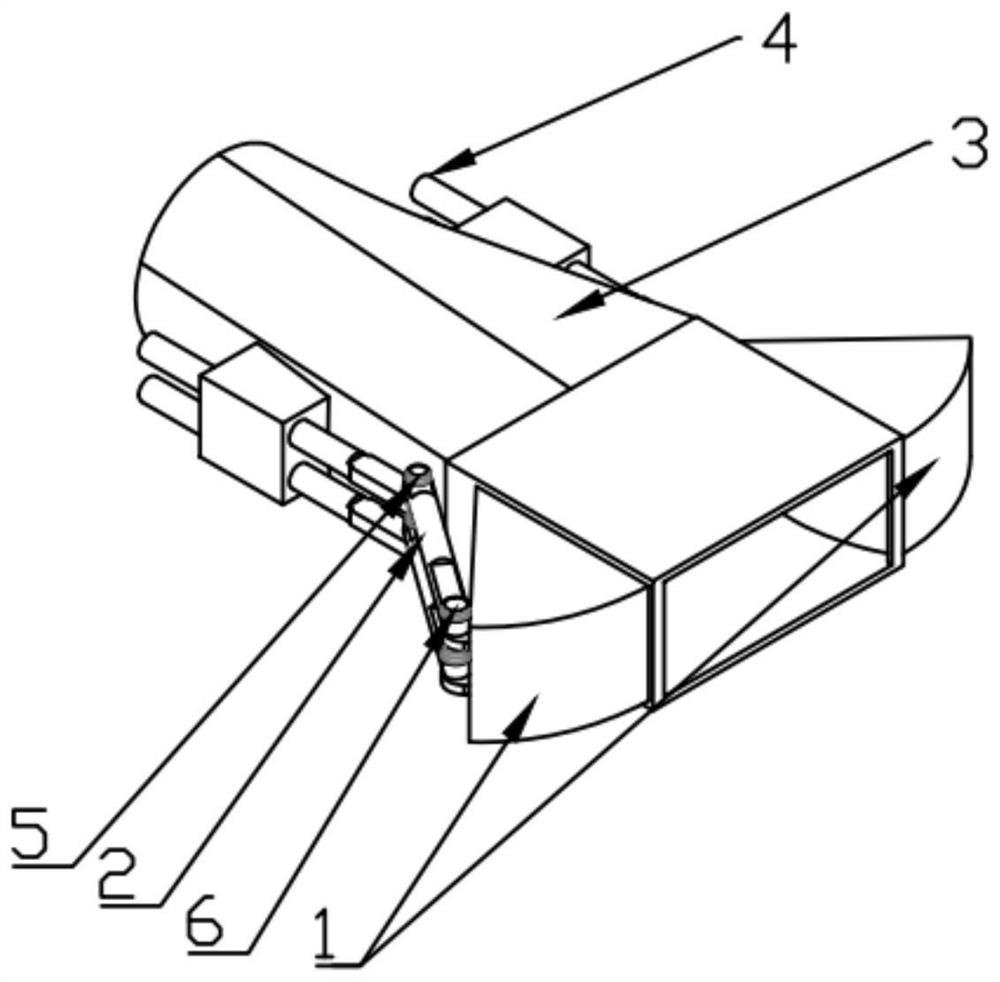

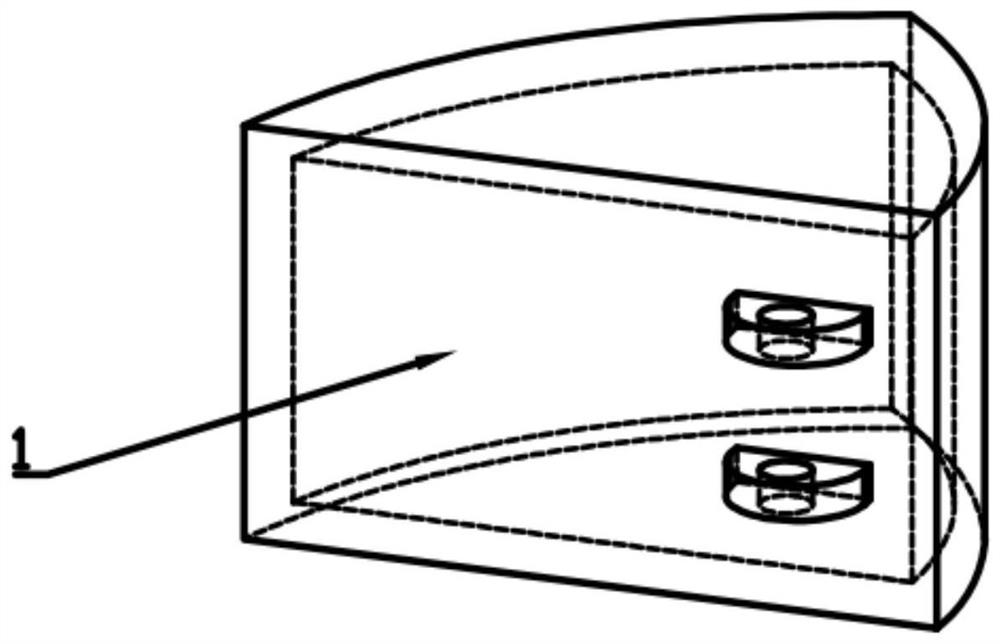

[0027] The present invention is based on the principle of double-paddle type slider, the slider design of the present mechanism paddle type a special structure, the use of two sets of the sheet reaches the point of tangency of the slider can be made fully closed rectangular duct characteristics, as designed figure 1 Tailpipe adjustment mechanism shown. The adjusting mechanism comprises tailpipe paddle type slider 1, round to rectangular tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com