Track-laying vehicle loading wheel load test device

A technology for load testing and road wheels, which is applied in the field of tracked vehicle road wheel load test devices, can solve the problems of inaccurate measurement and inability to realize the load measurement of double-spoke wheel flanges, and achieve the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

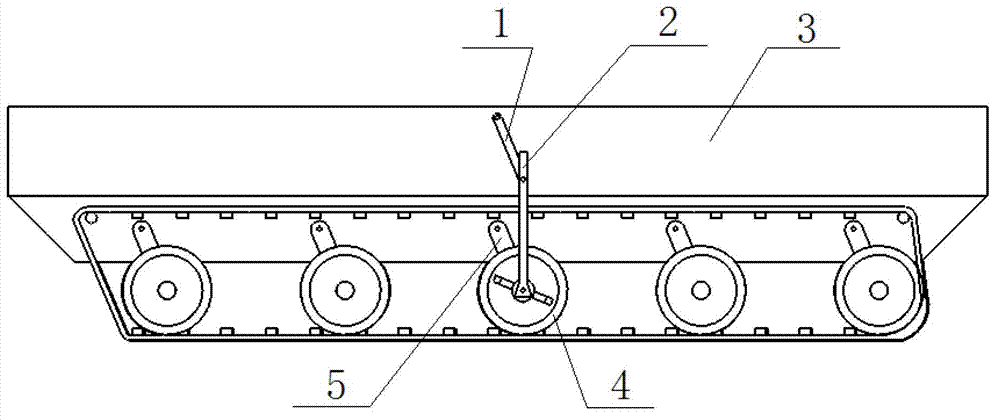

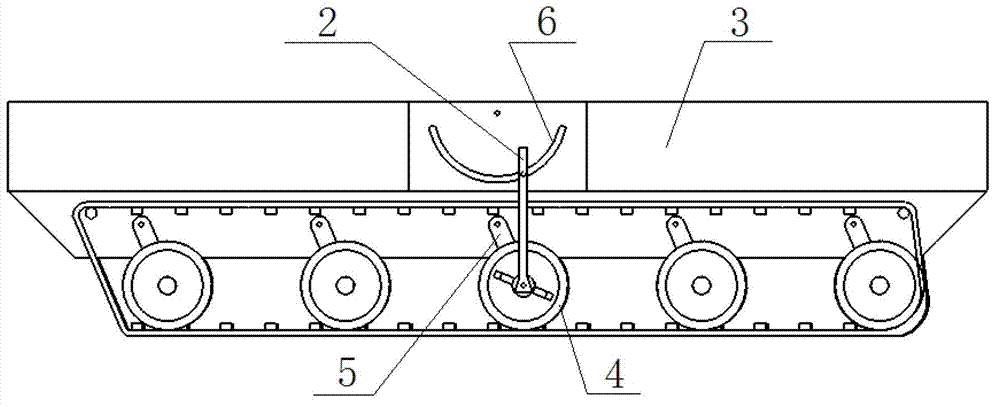

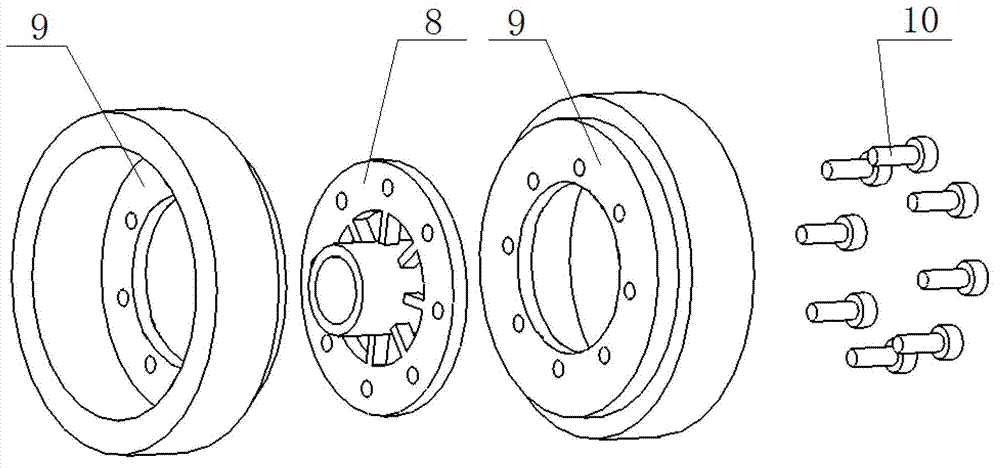

[0018] A tracked vehicle road wheel load testing device, comprising a road wheel 4 and a multi-component force sensor 8, is characterized in that: figure 1 and figure 2 As shown, a slip ring orientation system is also included, and the slip ring orientation system adopts a connecting rod system or a guide rail system; the hub of the road wheel 4 is a spoke-type hub 9 or a spoke-type hub 11, such as image 3 and Figure 4 As shown, a round hole is set in the middle of the spoke plate or spoke type hub, the diameter of the round hole is larger than the outer diameter of the central sleeve 7 of the multi-component force sensor, and several bolt holes are arranged on the circumference concentric with the round hole; as Figure 5 As shown, the multi-component force sensor is located in the middle of the two wheel rims and is bolted to the middle of the web-type or spoke-type hub; the central sleeve of the multi-component force sensor is connected to the balance elbow 5 on the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com