Construction platform for facilitating root key construction of root type cast-in-place pile

A technology for construction platforms and cast-in-situ piles, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as high construction costs, slope restrictions, and high requirements for crane load-bearing capacity, and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

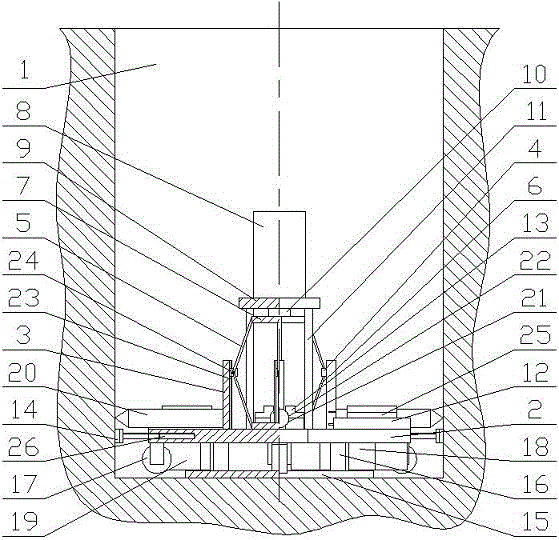

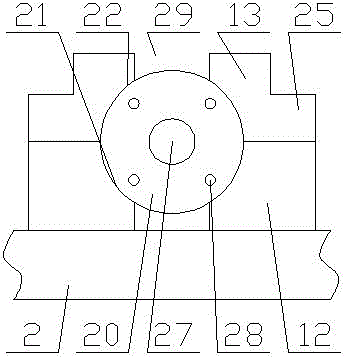

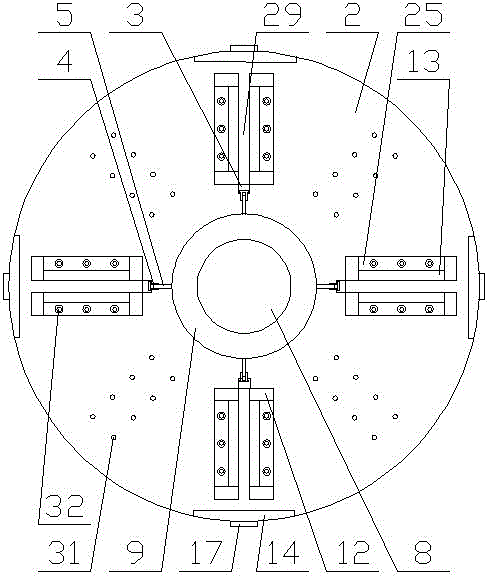

[0070] combine Figure 1~Figure 6 As shown, the present invention includes a base plate 2, a hydraulic cylinder 8 is fixed above the center of the base plate 2, and the end of the hydraulic rod 10 of the hydraulic cylinder 8 protrudes downward toward the base plate 2, and the base plate 2 is located on the hydraulic cylinder There are many vertical push rods 3 evenly distributed around 8 (the present invention can have 8 vertical push rods 3 evenly distributed around the hydraulic cylinder 8 on the base plate 2 at most, and only 4 vertical push rods 3 are evenly distributed in this embodiment. type push rod 3), the hydraulic rod 10 is connected with the vertical push rod 3 through a linkage mechanism, so that the vertical push rod 3 moves along the radial direction of the base plate 2, and the edge of the upper surface of the base plate 2 corresponds to the vertical The push rods 3 are respectively provided with a root key limiting device, the root key limiting device makes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com