Power takeoff shift fork fixture

A technology for power take-off and fork clamp, which is applied in the field of power take-off fork processing, can solve the problems of increased processing cost of intensive training, low production efficiency of power take-off fork, and difficult installation of tooling and fixtures, so as to avoid processing positioning. The effect of complex, compact structure and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

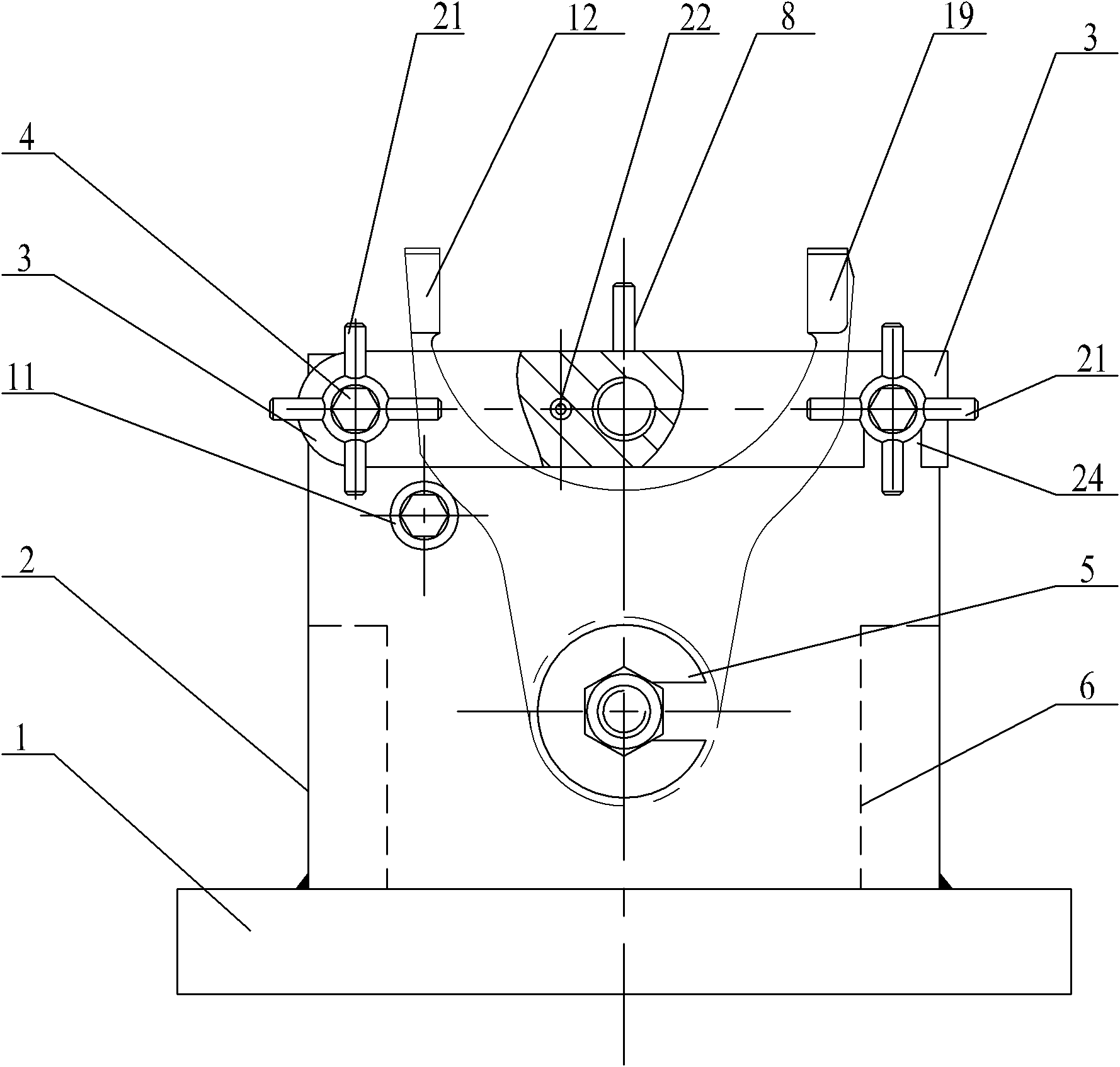

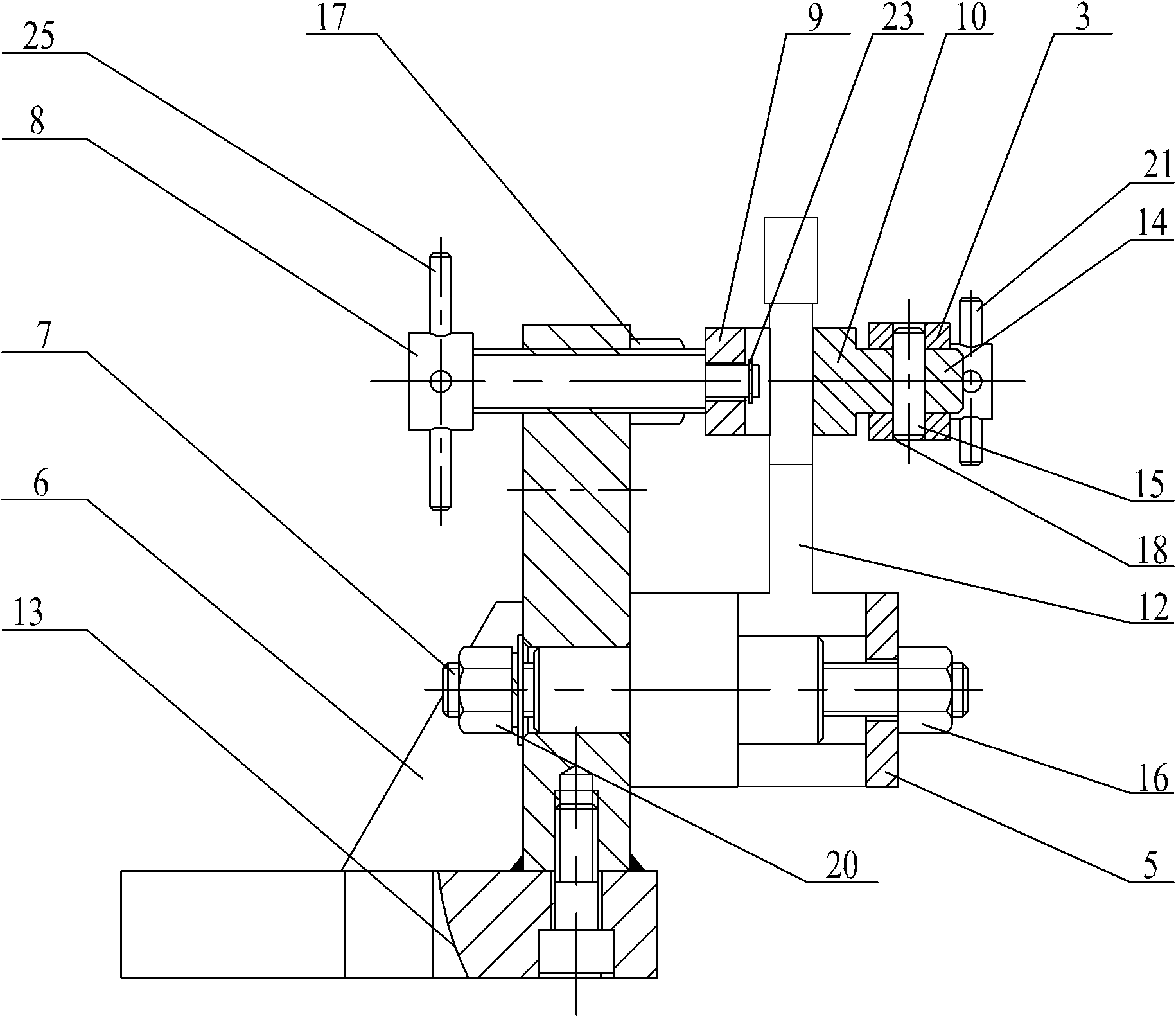

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

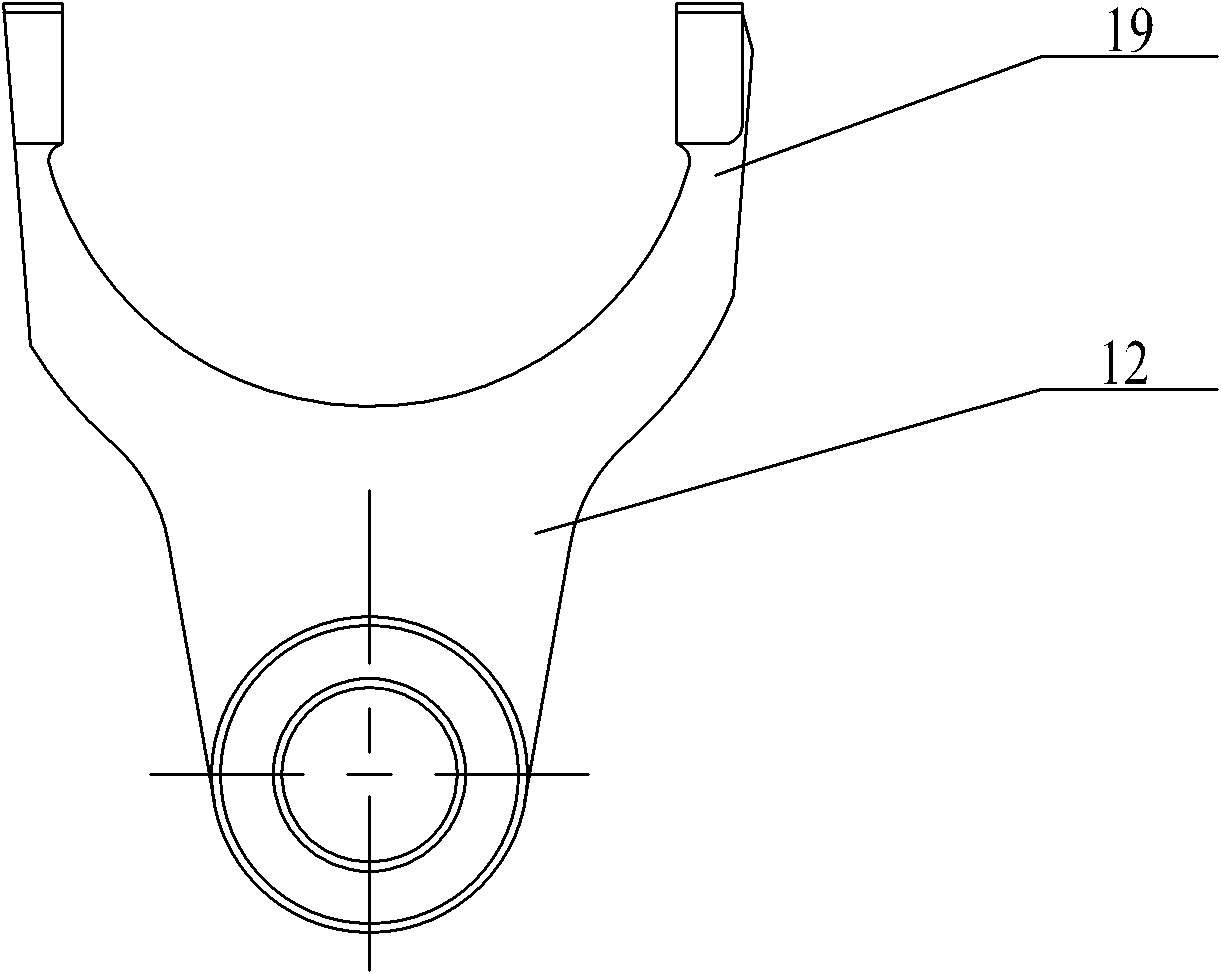

[0016] Such as Figure 1~Figure 4 As shown: the present invention includes a base plate 1, a flat plate 2, a clamping plate 3, a first bolt 4, an opening plate 5, a reinforcing rib 6, a positioning pin 7, a second bolt 8, a support plate 9, a movable platen 10, and an eccentric screw 11 , PTO shift fork 12, base 13, positioning bump 14, pressure plate positioning pin 15, first nut 16, second nut 17, positioning hole 18, power take-off fork thin arm 19, third nut 20, The first locking pin 21 , the supporting plate positioning pin 22 , the retaining ring 23 , the clamping plate opening 24 and the second locking pin 25 .

[0017] Such as figure 1 with figure 2 As shown: the base 13 includes a base plate 1 on which a vertically distributed flat plate 2 is arranged, and reinforcing ribs 6 are provided at both ends of the joint between the flat plate 2 and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com