Annular water curtain device

A water curtain and ring-shaped technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of difficult product quality assurance, narrow cooling range, uneven cooling, etc., to achieve no dead angle cooling, Good cooling effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

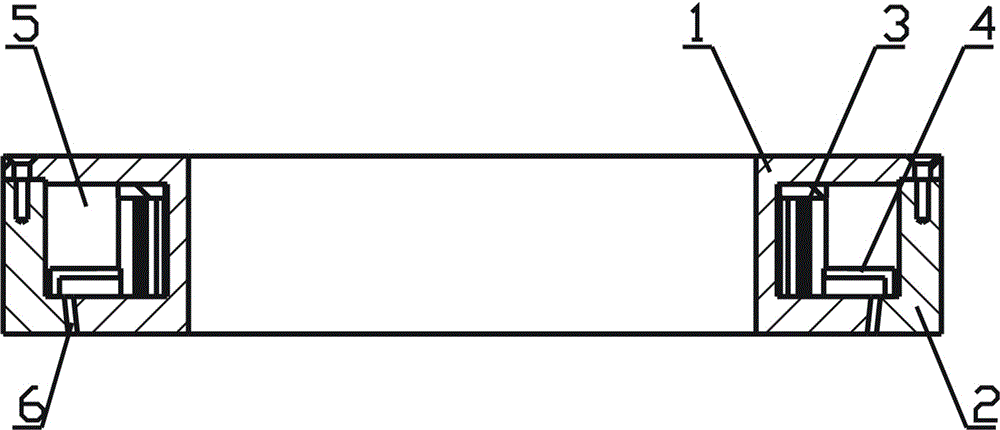

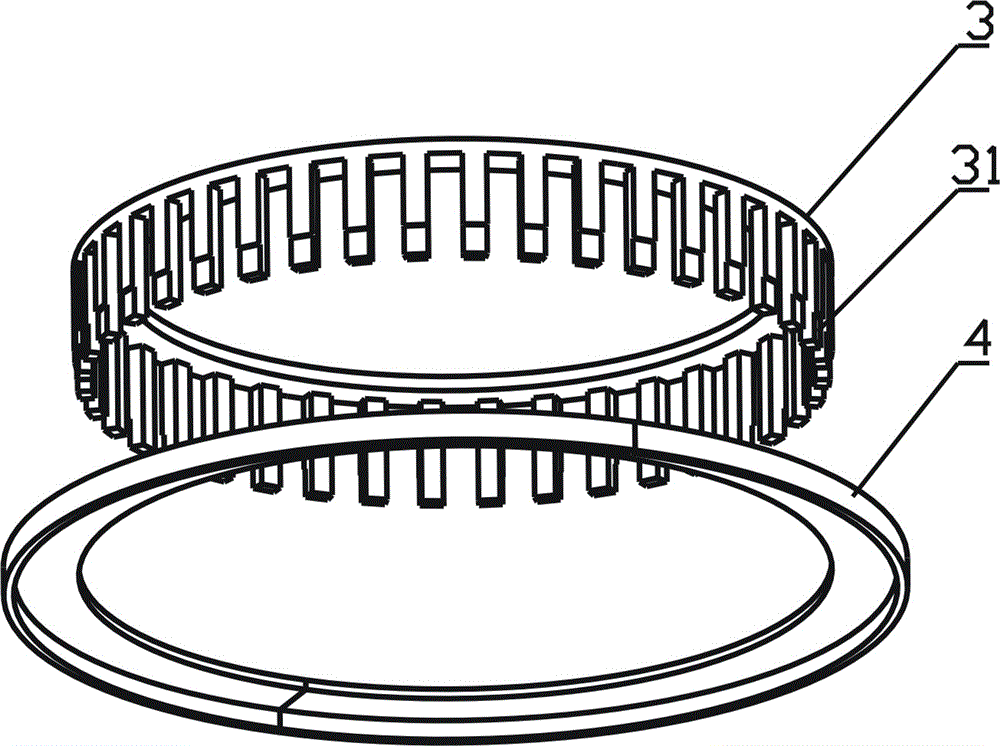

[0012] Such as figure 1 As shown, an annular water curtain device of the present invention is composed of a water curtain inner ring 1 , a water curtain outer ring 2 , a slow flow plate inner ring 3 and a slow flow plate outer ring 4 . The water curtain inner ring 1 and the water curtain outer ring 2 are fixedly installed together to form an annular water holding space 5 inside, wherein the radial section of the water curtain inner ring 1 is an inverted I-shaped structure, and the outer edge of the bottom is a slope, and The slope of the water curtain outer ring 2 cooperates to form an annular tapered water outlet 6 with a certain width, which can make the formed water curtain have a certain taper.

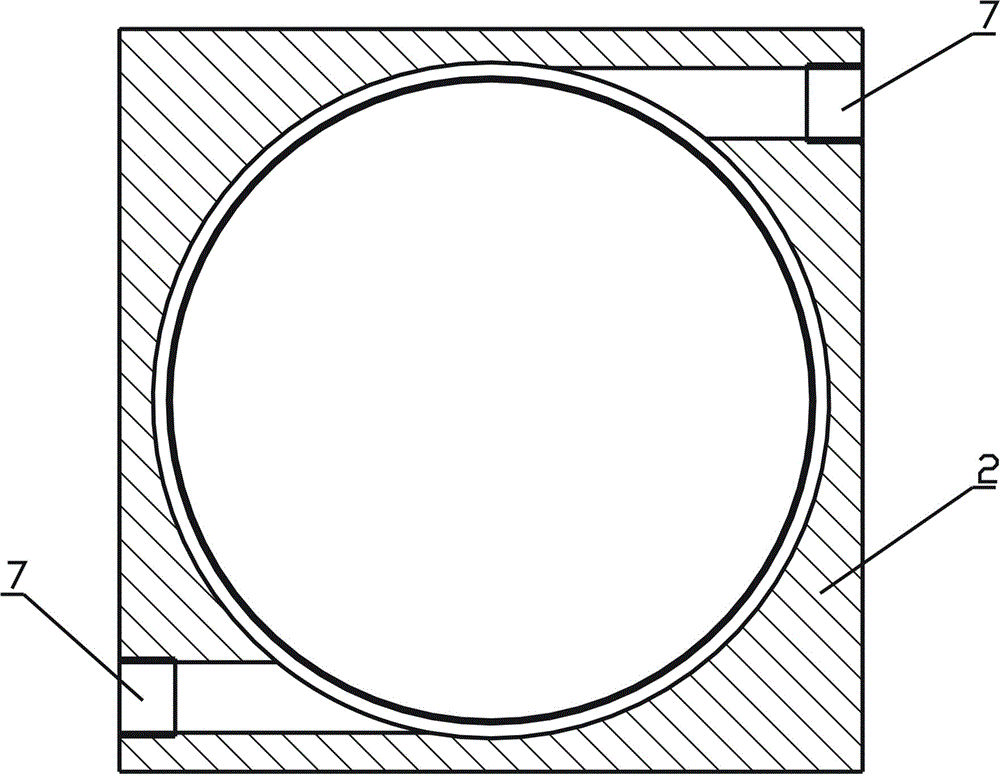

[0013] Such as figure 2 As shown, two water inlets 7 leading to the water holding space are diagonally distributed on the outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com