Sheet Processing Device, Image Forming Device Provided With The Same, And Sheet Bonding Method

一种处理装置、片材的技术,应用在薄料处理、折叠薄材料、运输和包装等方向,能够解决片材堵塞等问题,达到减小应力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

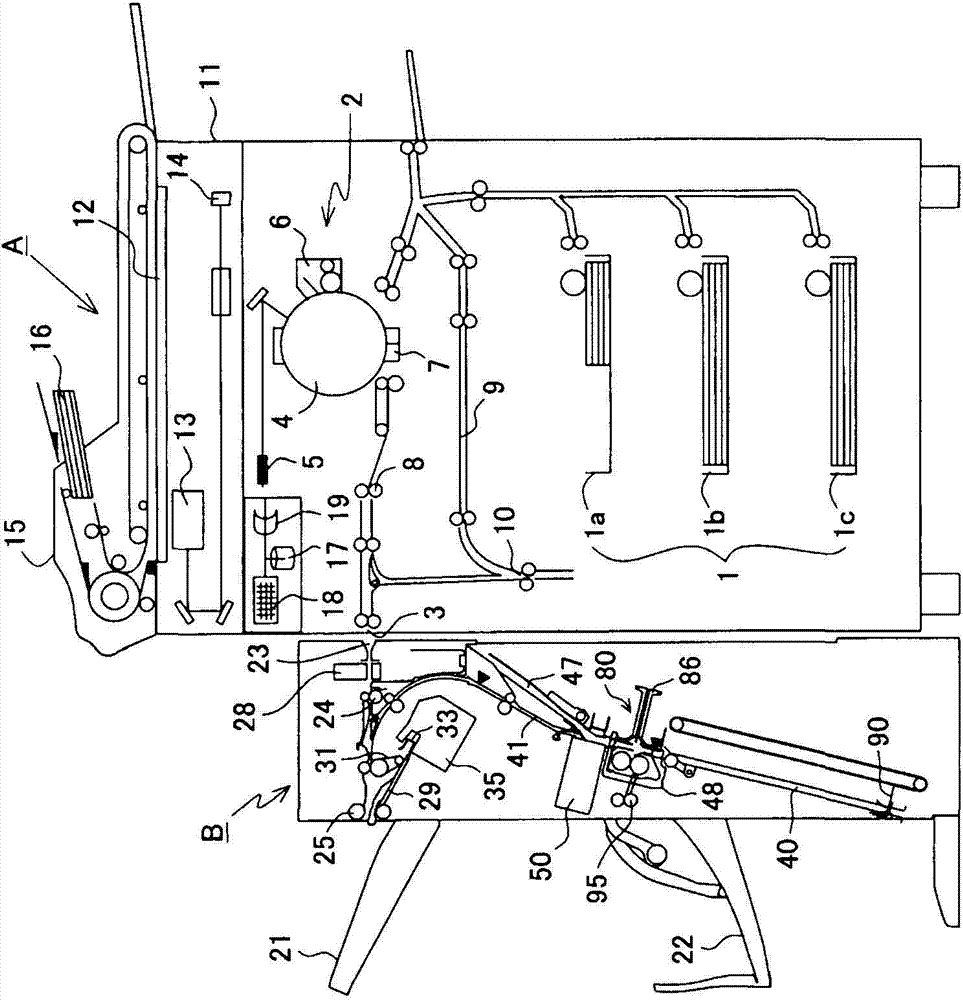

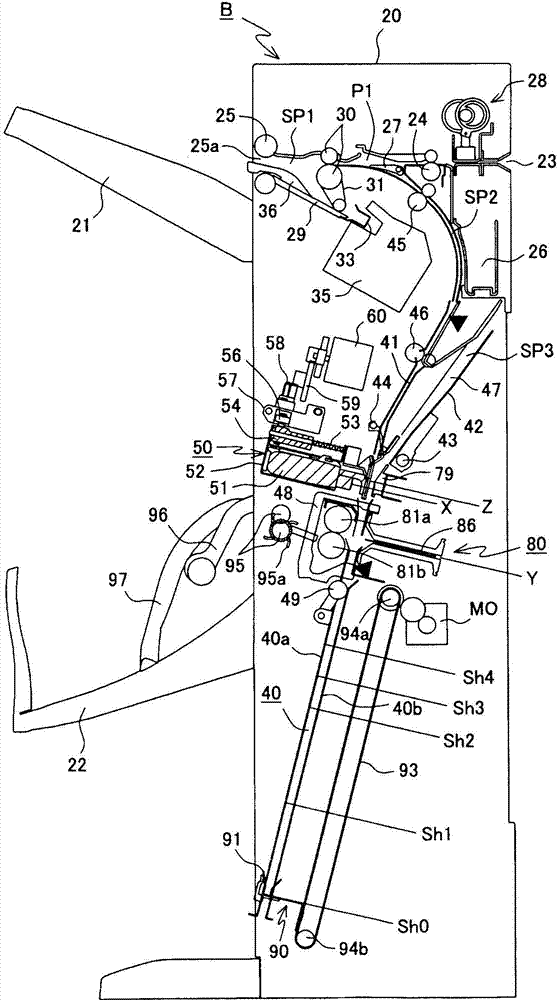

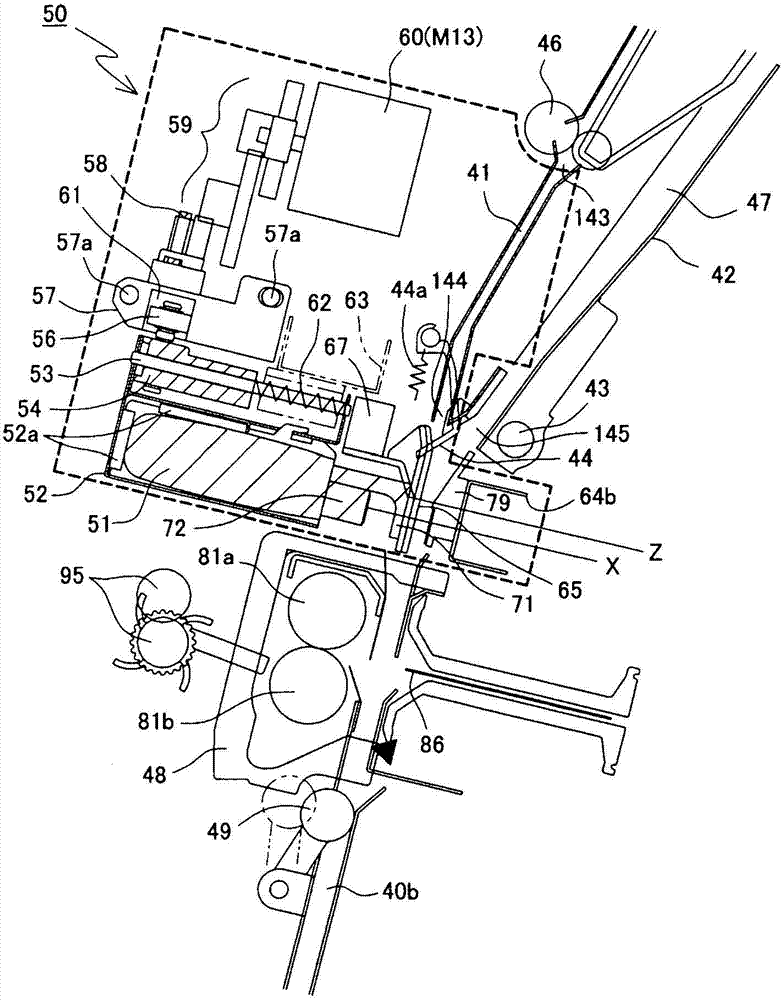

[0046] Hereinafter, the present invention will be described in detail based on illustrated preferred embodiments. figure 1 is a diagram showing the overall configuration of the combined image forming apparatus and post-processing apparatus of the present invention, figure 2 is an explanatory diagram of the overall structure of the sheet processing apparatus, image 3 The following are explanatory diagrams showing the mechanical configuration of the sheet processing apparatus. therefore, figure 1 The shown apparatus is composed of an image forming apparatus A and a sheet processing apparatus B, and an adhesive application apparatus 50 as a unit is incorporated in the sheet processing apparatus B.

[0047] [Structure of Image Forming Apparatus]

[0048] figure 1 In the illustrated image forming apparatus A, a sheet is sent from a paper feeding unit 1 to an image forming unit 2 , and after printing is performed on the sheet by the image forming unit 2 , the sheet is deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com