Packaging paper feeding mechanism

A paper feeding mechanism and wrapping paper technology, which is applied in the directions of transportation and packaging, sending objects, winding strips, etc., can solve the problems of complex structure, poor paper feeding accuracy and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

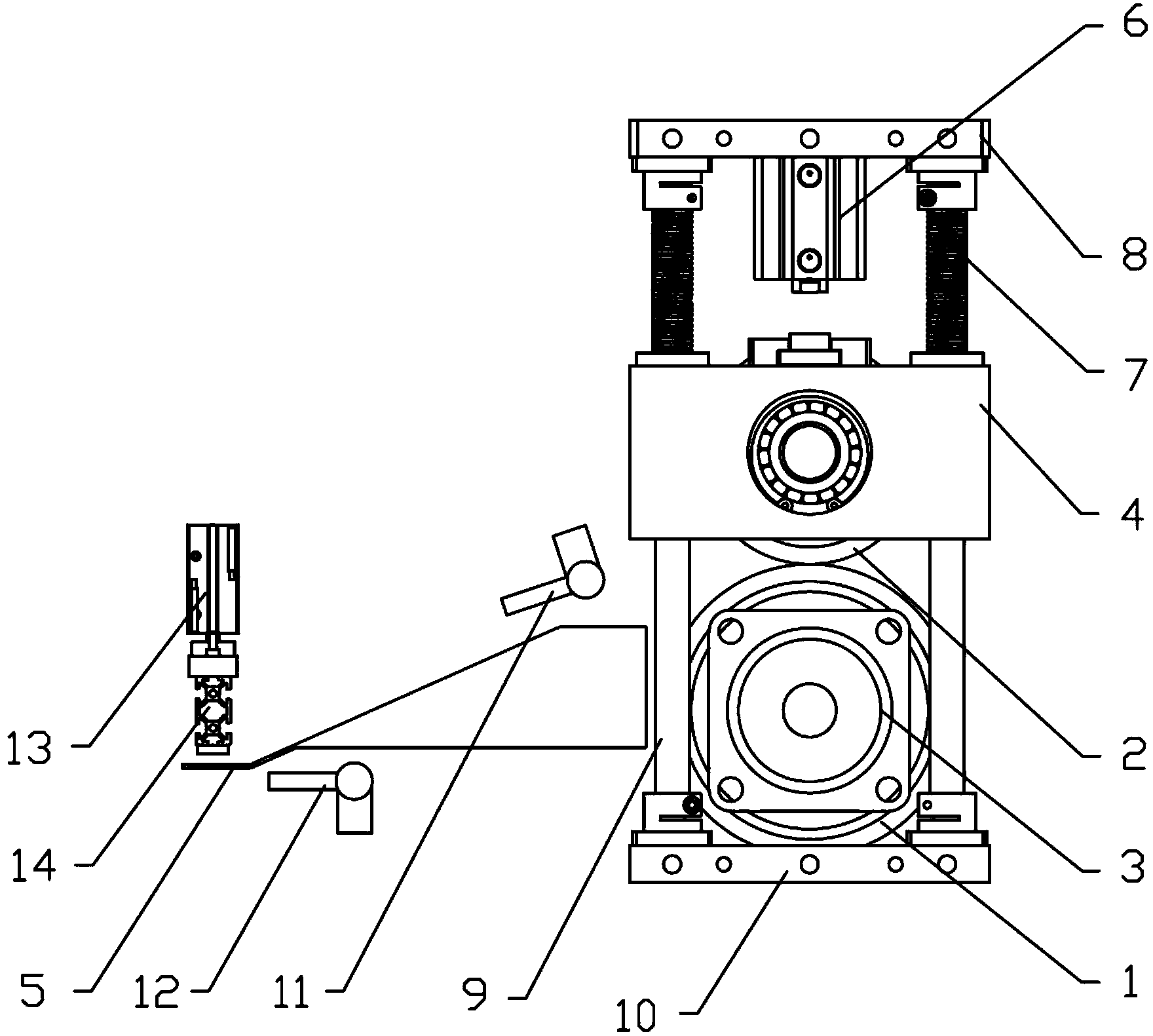

[0029] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

[0030] The packaging paper feeding mechanism includes a roller conveying unit and an air blowing guide unit. The paper thickness adjusting device is connected with the roller conveying unit. The paper thickness adjusting device is arranged above the roller conveying unit. The output of the roller conveying unit The air blowing guide unit is connected with the input end of the air blowing guide unit. The air blowing guide unit is provided with an antistatic device. The antistatic device (not shown in the figure) can remove the static electricity on the surface of the guide plate 5 and prevent the paper of some special materials from contacting the guide plate. 5 Absorbed and stopped, the roller conveying unit includes driving roller 1 and passive roller 2, through the paper thickness adjustment device, the passive roller 2 changes the distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com