Attaching method of steel sheet enhancing sheets of flexible circuit board, jigs of flexible circuit board, and strip attaching steel sheets of flexible circuit board

A flexible circuit board and reinforcing sheet technology, applied in the directions of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve problems such as reduced efficiency and low production efficiency, and achieve the effect of improving accuracy and improving lamination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

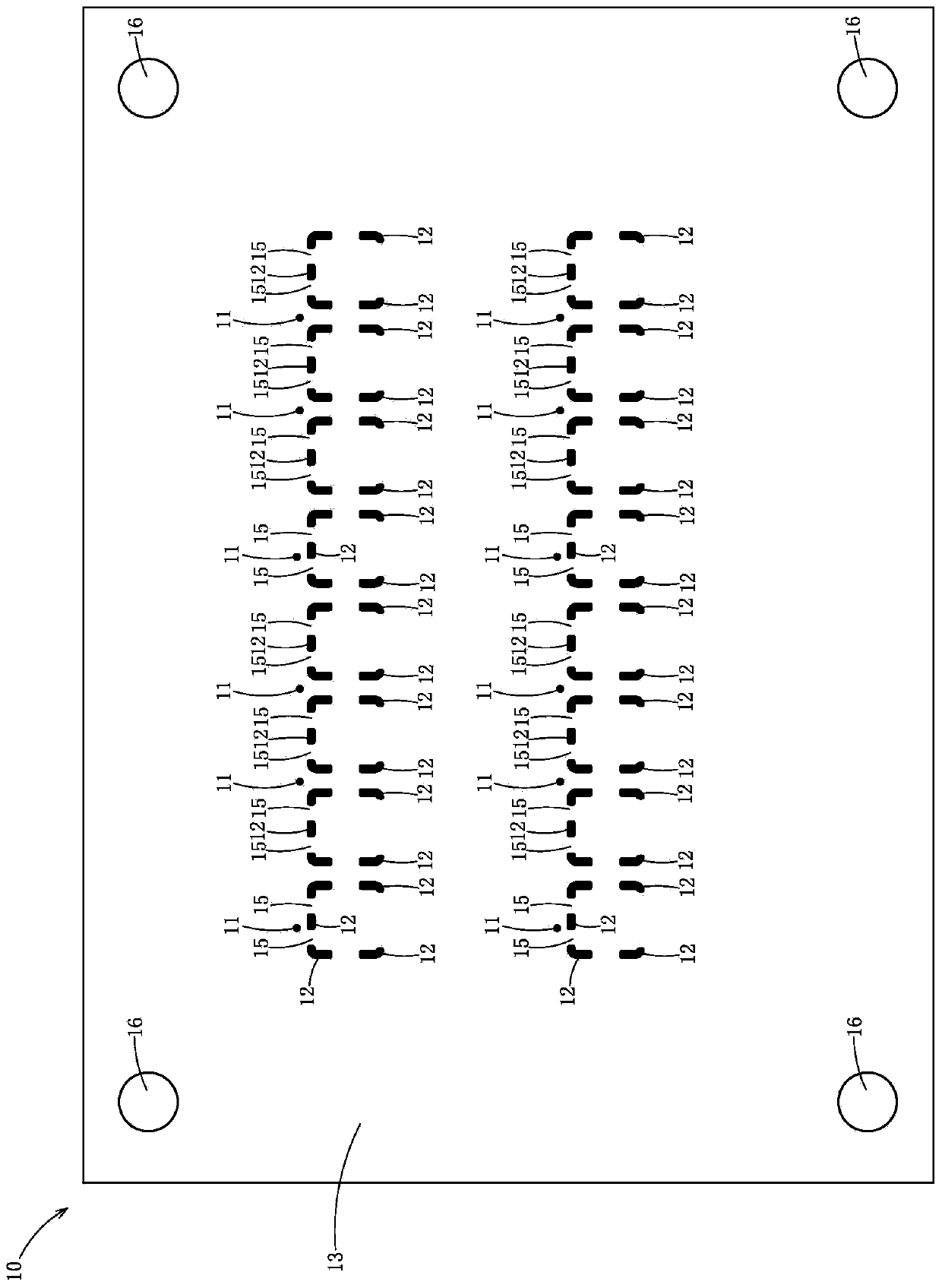

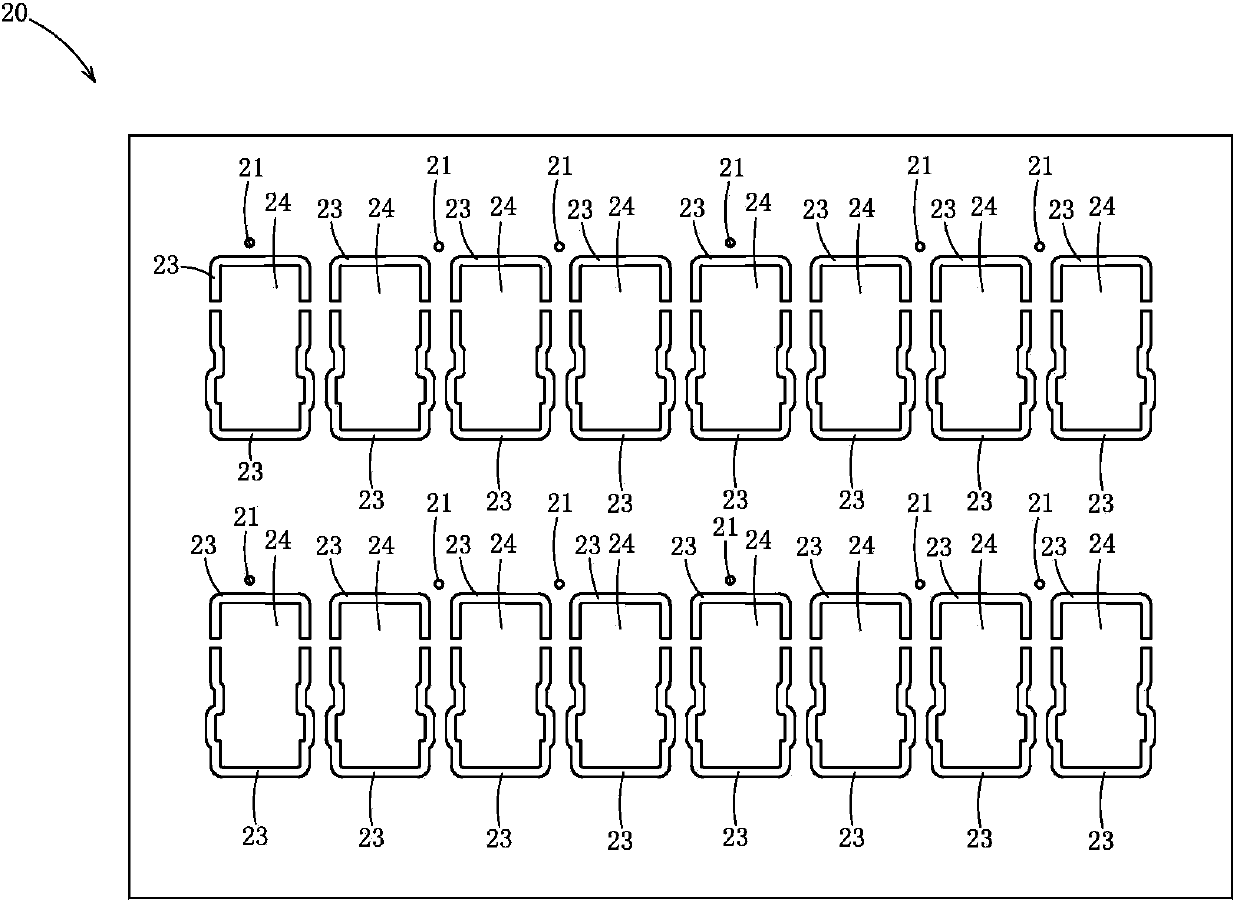

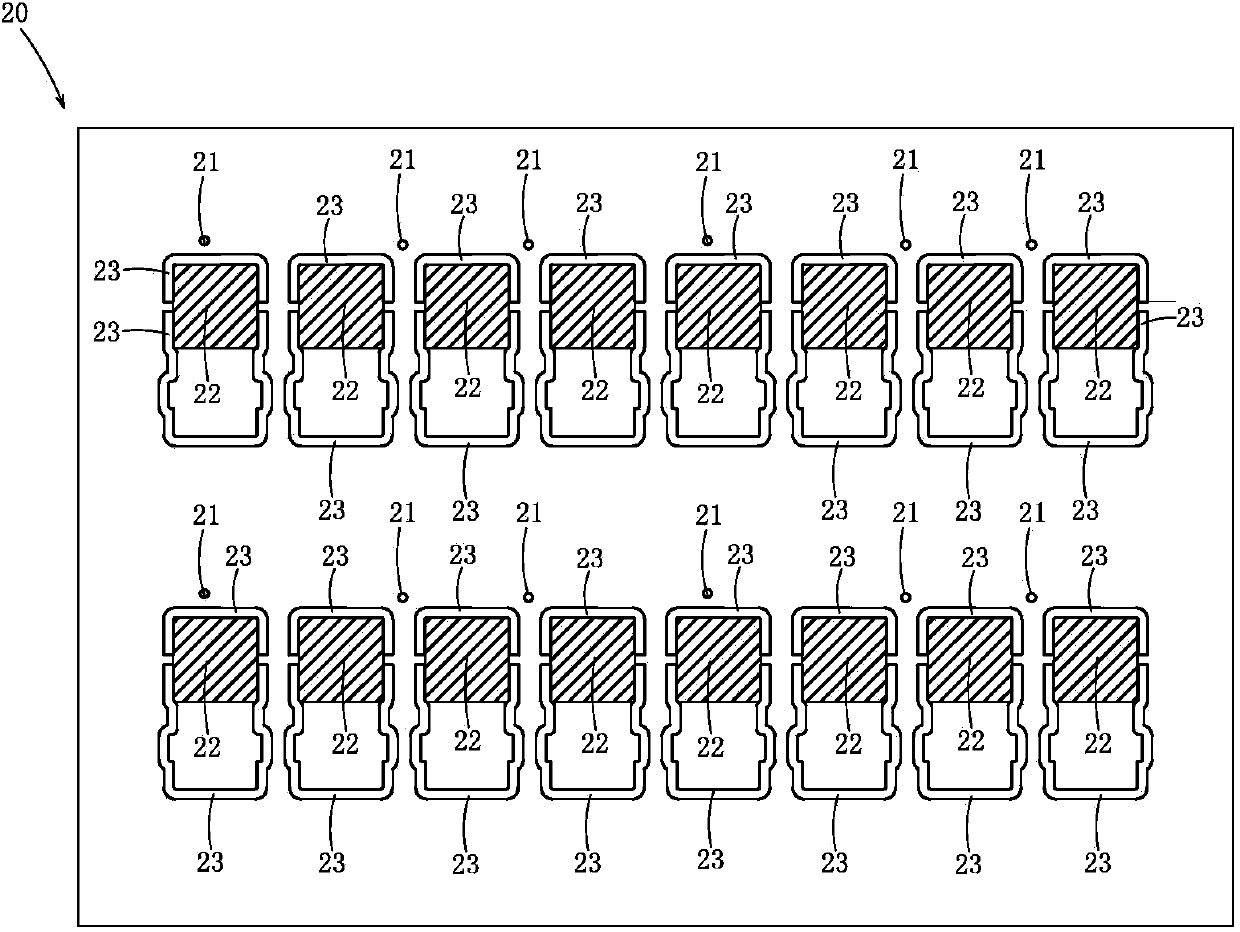

[0035] The present invention is applicable to flexible circuit boards that have been grooved according to design requirements, such as figure 2 The front view of the flexible circuit board 20 shown, the flexible circuit board 20 has two rows of grooves 23, each row is provided with 8 grooves 23, and the upper part of the area surrounded by each groove 23 is adapted to the shape of the steel reinforcement sheet The reinforcement sheet attachment position 24, each reinforcement sheet attachment position 24 is covered with pure glue 22, such as image 3 shown. At least three first positioning holes 21 with different intervals are provided above each row of grooves 23 , specifically, three first positioning holes 21 with different intervals are arranged above every four grooves 23 . The shape and quantity of the grooves 23 are not limited to this embodiment, and can be set according to the design requirements, and it is only necessary to leave the reinforcing sheet attaching pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com