Backlight module and liquid crystal display device using the backlight module

A backlight module and backplane technology, which is applied in the direction of lighting devices, fixed lighting devices, lighting device components, etc., can solve the problems of inappropriateness, high cost of elastic metal sheets, and small deformation of optical diaphragms, etc., and achieve reduction Probability of bending deformation, increased brightness, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

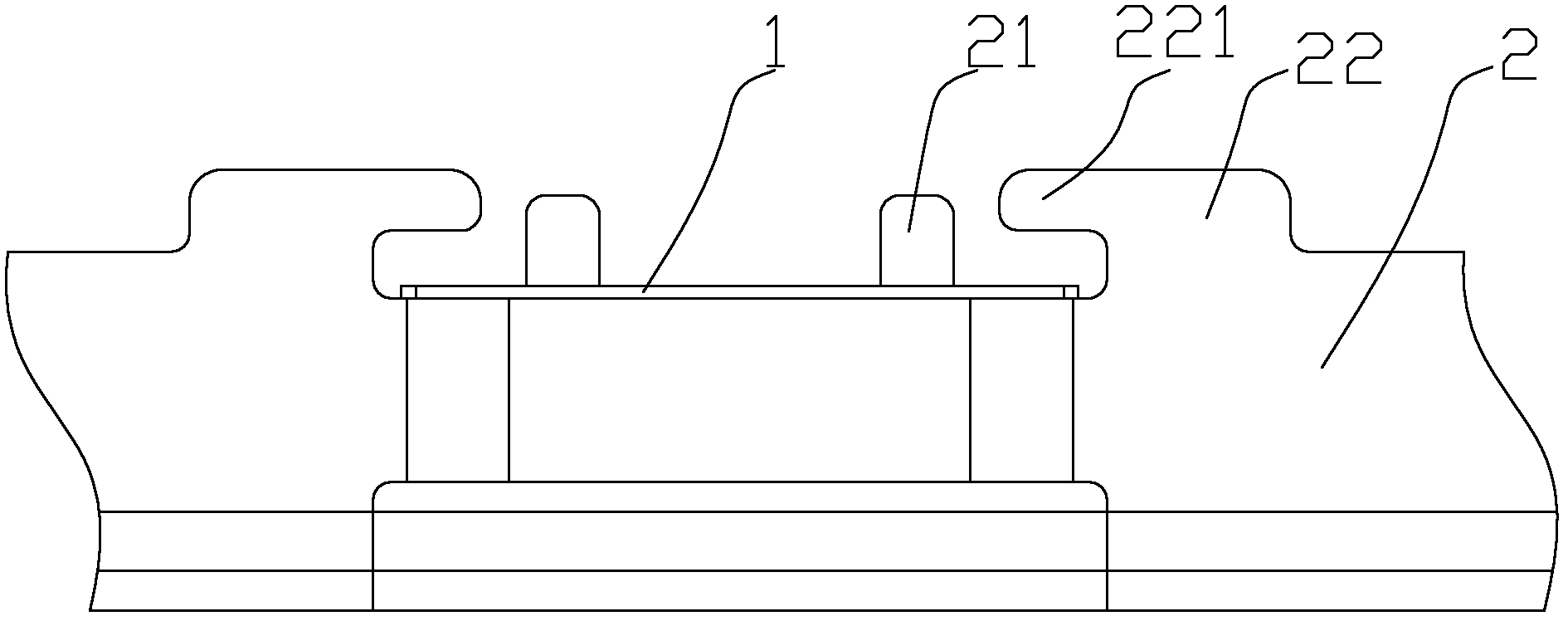

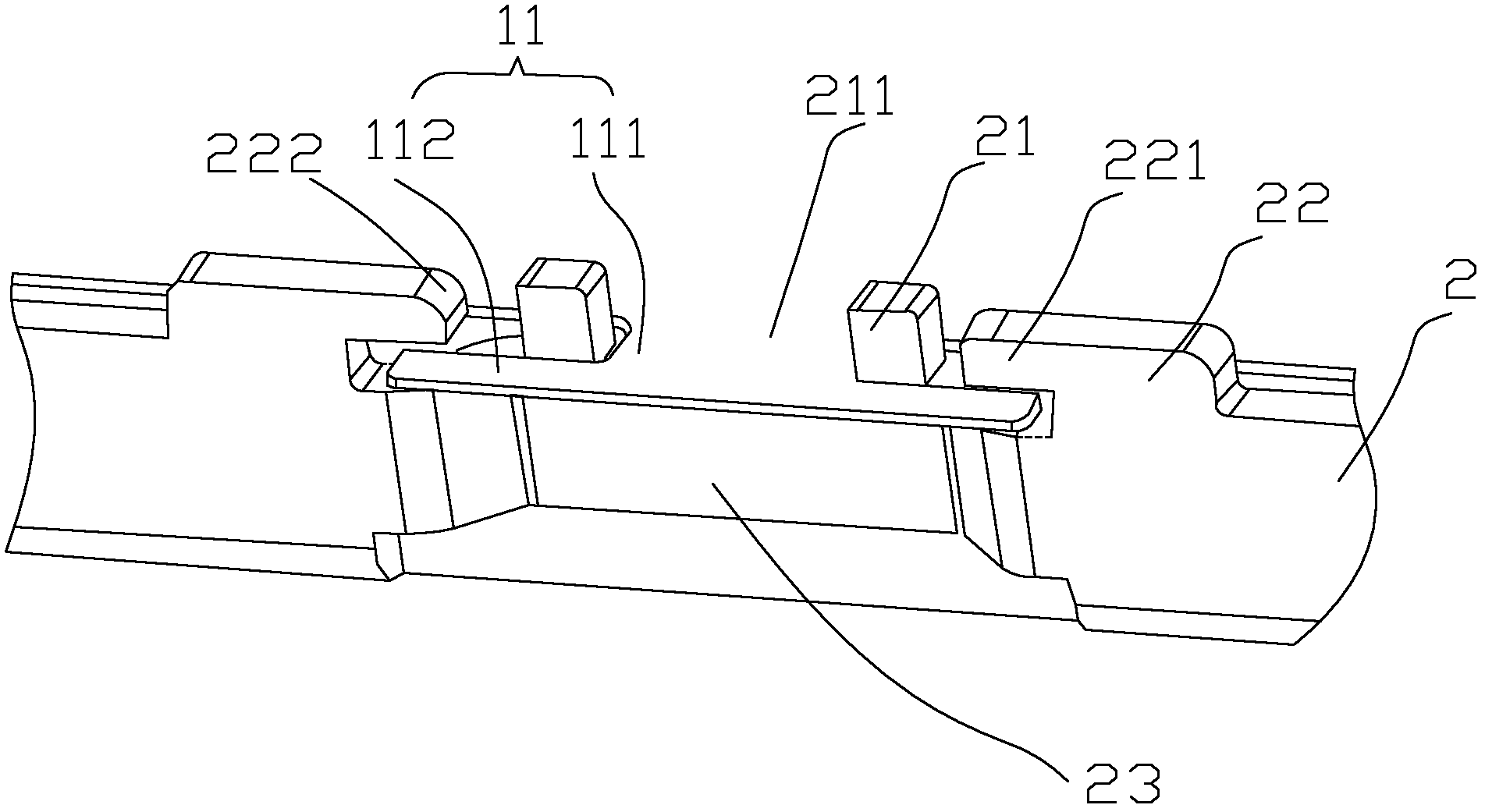

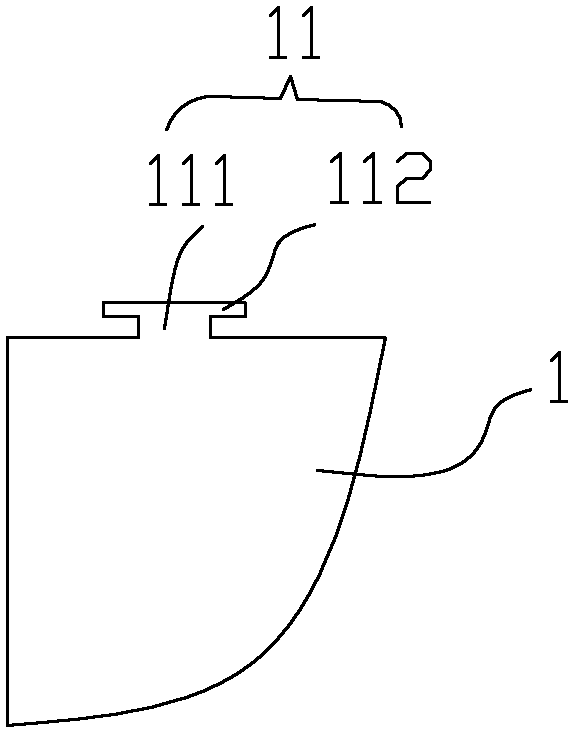

[0023] The invention discloses a liquid crystal display device, including a backlight module, as an embodiment of the backlight module of the invention, such as Figures 1 to 3 As shown, the backlight module includes a backplane 2 and an optical film 1 arranged on the backplane 2. The optical film 1 is provided with a lug 11 for positioning, and the lug 11 has a part 111 and a The expansion part 112 extending outward, the width of the expansion part 112 is greater than the width of the root part 111, the side wall of the backboard 2 is provided with a first protrusion 21, and the first protrusion 21 is provided with an opening 211, The root 111 of the lug 11 of the optical film 1 is accommodated at the opening 211, and the side wall of the back plate 2 is further provided with a second protrusion 22, and the second protrusion 22 has an extension 221, The expanded portion 112 of the lug 11 of the optical film 1 is accommodated below the extension portion 221 of the second protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com