Linear compressor with sensor

a sensor and compressor technology, applied in the direction of positive displacement liquid engine, piston pump, pump parameter, etc., can solve the problems of increasing manufacturing costs, increasing assembly time, and sensor core b>120/b> not being easily fixed to the desired position of the core support member, so as to improve productivity and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Reference will now be made in detail to the embodiment of the present invention, an example of which is illustrated in the accompanying drawings. The embodiment is described below to explain the present invention by referring to the figures.

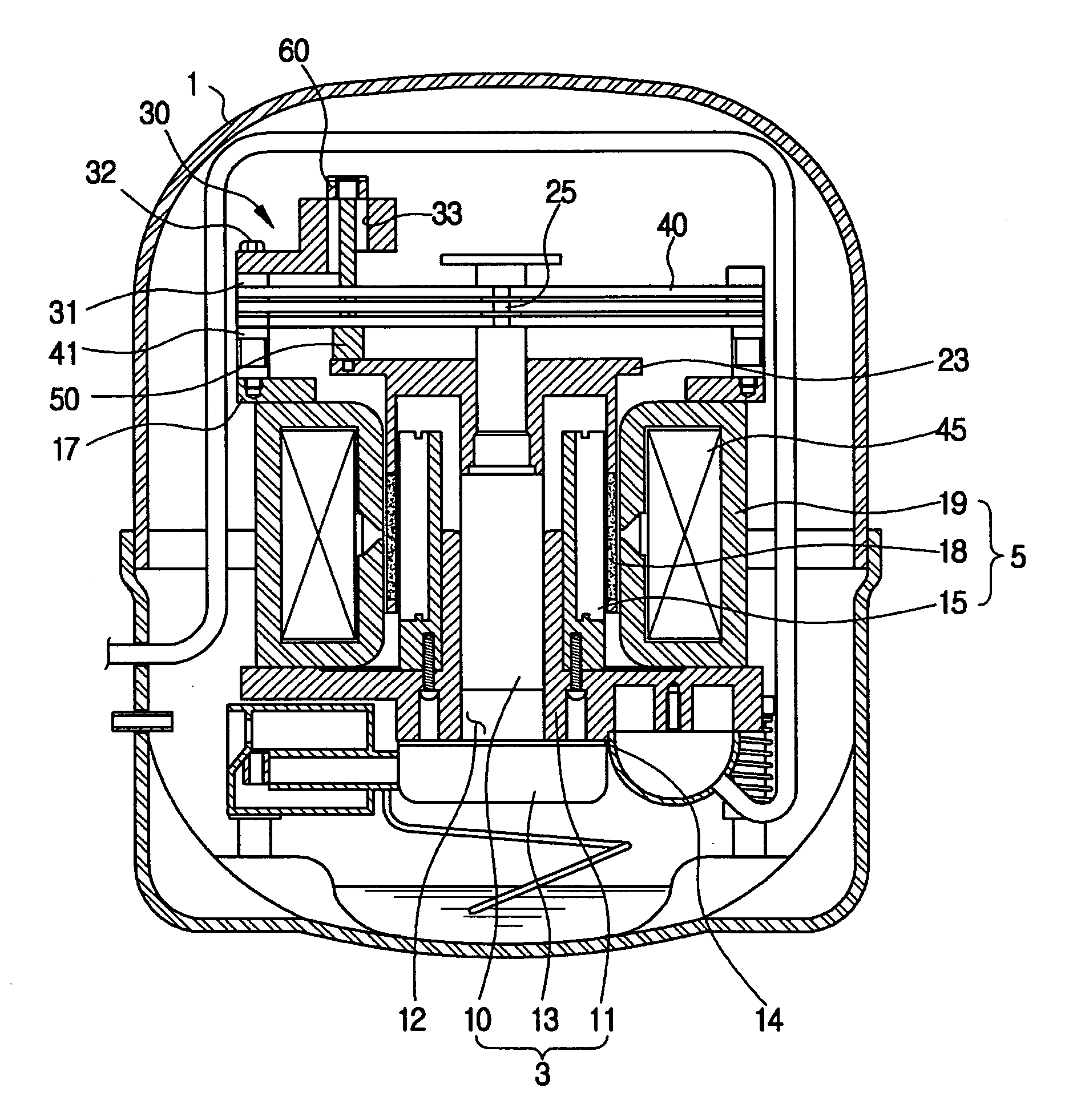

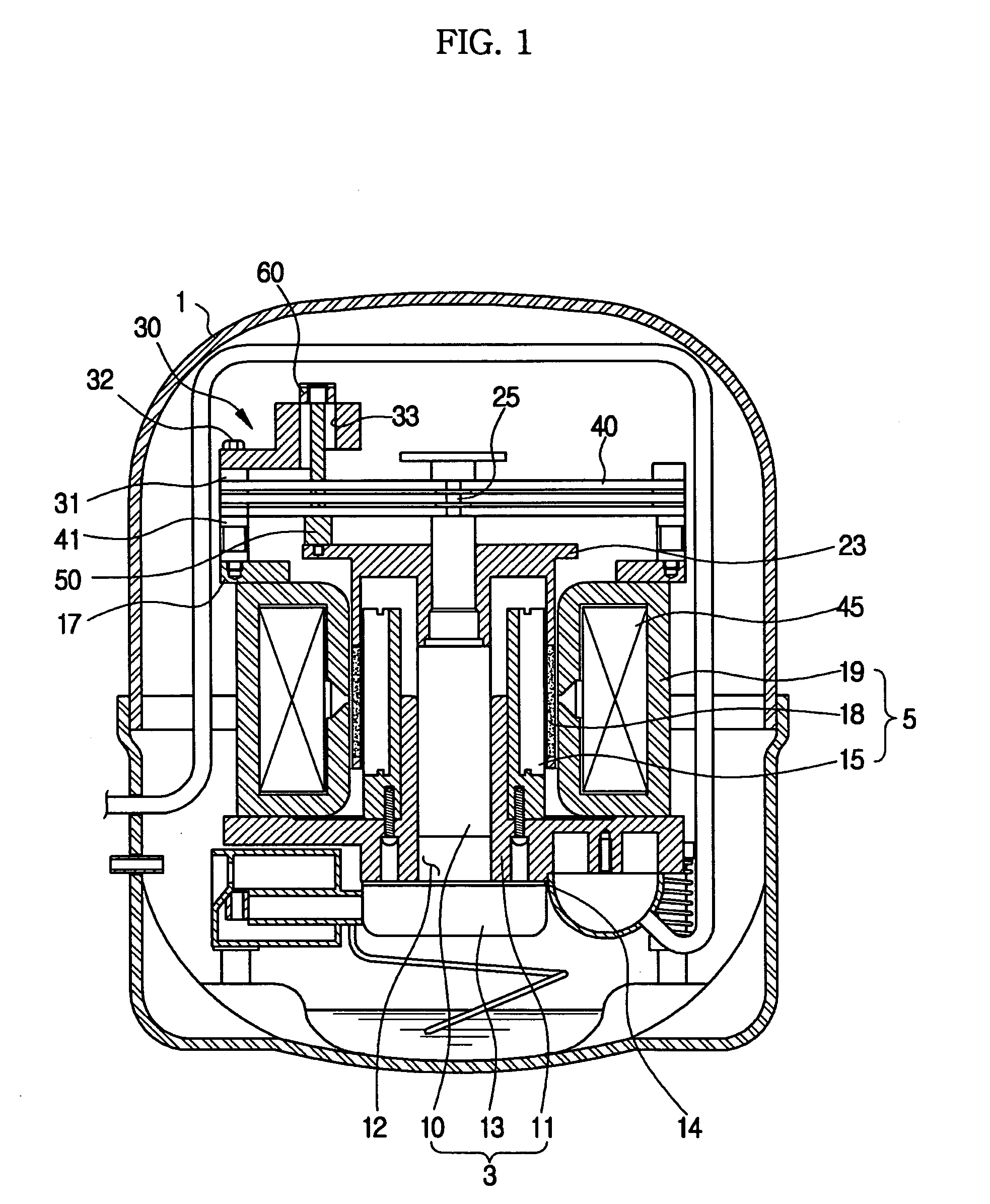

[0036]FIG. 1 is a sectional view showing a linear compressor according to the present invention. As shown in FIG. 1, the linear compressor comprises a hermetically sealed container 1, a compressing unit 3 for compressing a coolant, and a driving unit 5 for generating power.

[0037] The compressing unit 3 includes a cylinder block 11 forming a compression chamber 12, a piston 10 disposed in the compression chamber 12 such that the piston 110 can be reciprocated in the compression chamber 12, and a cylinder head 13 provided at the lower part of the cylinder block 11. The cylinder head 13 has a coolant-introducing chamber (not shown) and a coolant-discharging chamber (not shown) defined therein. Between the cylinder block 11 and the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com