Patents

Literature

43results about How to "Solve the problem of manual feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

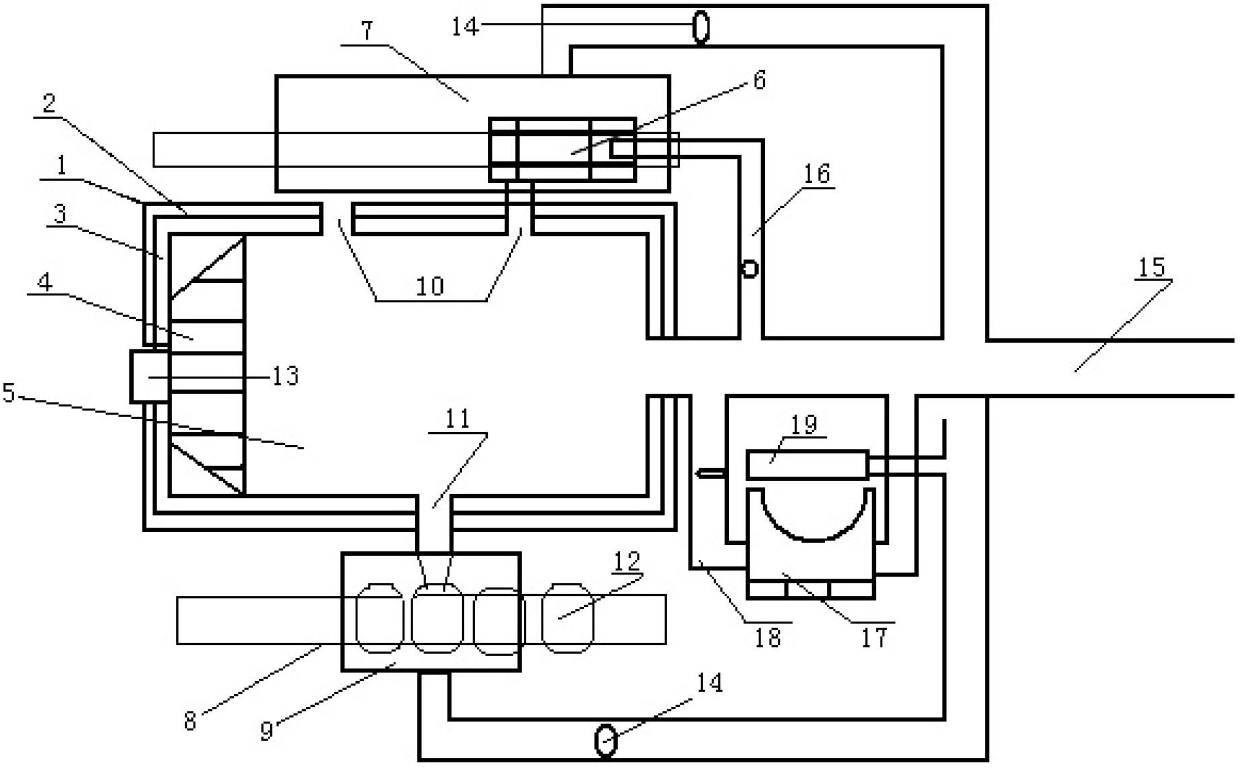

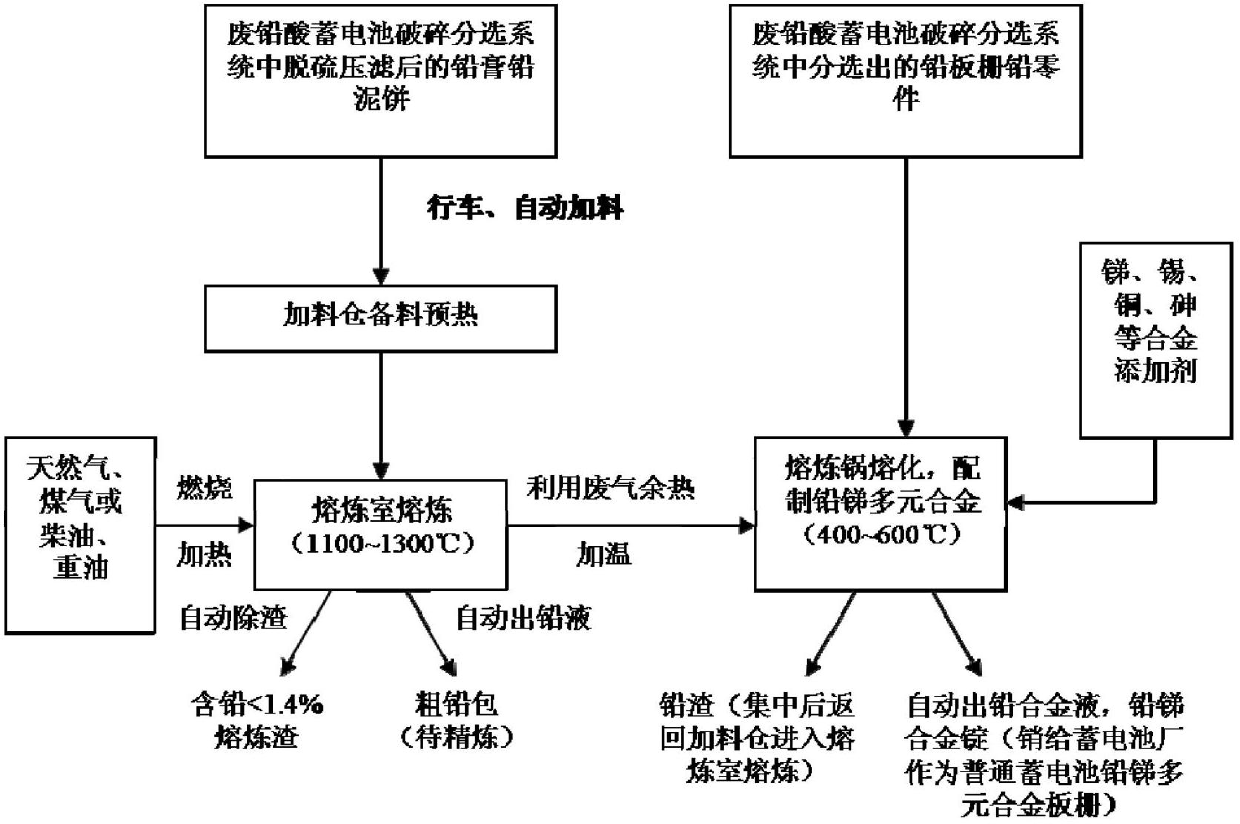

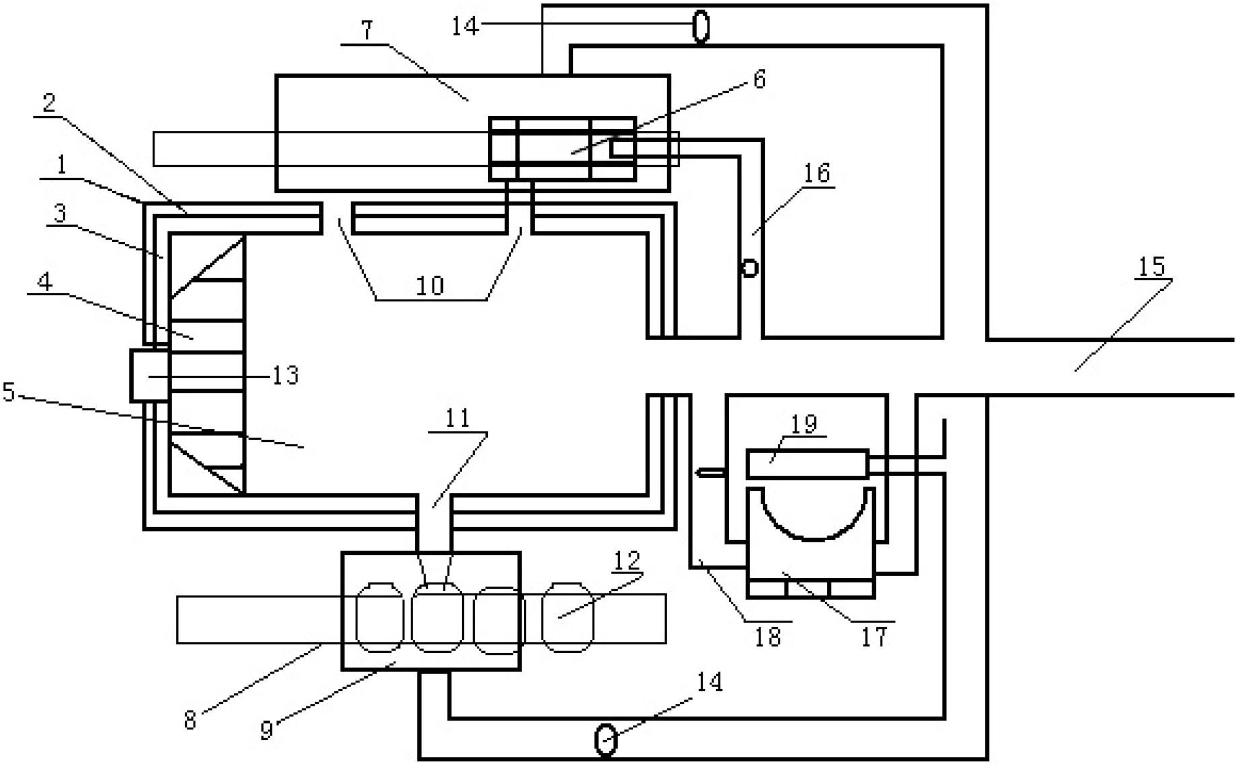

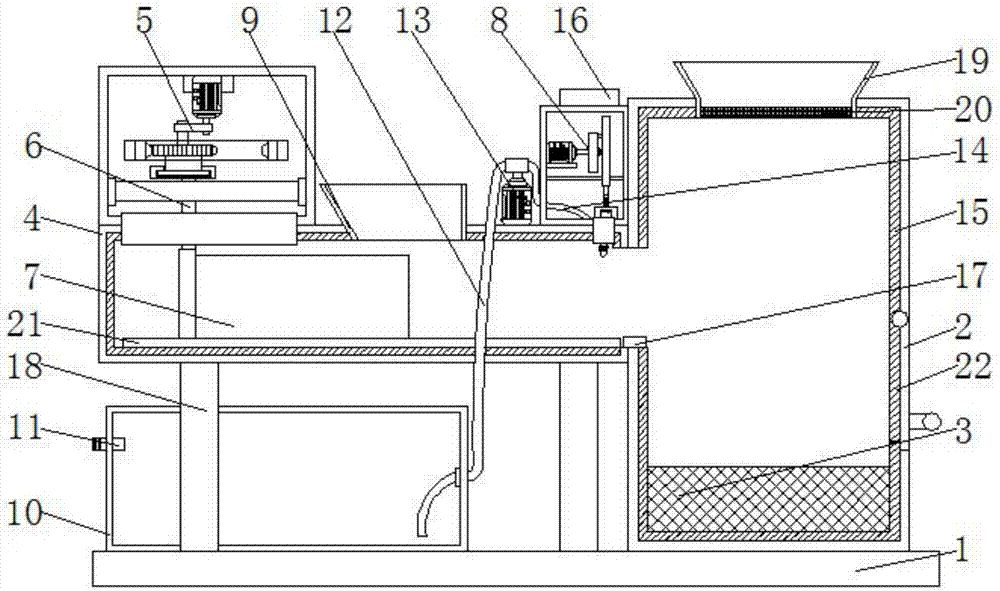

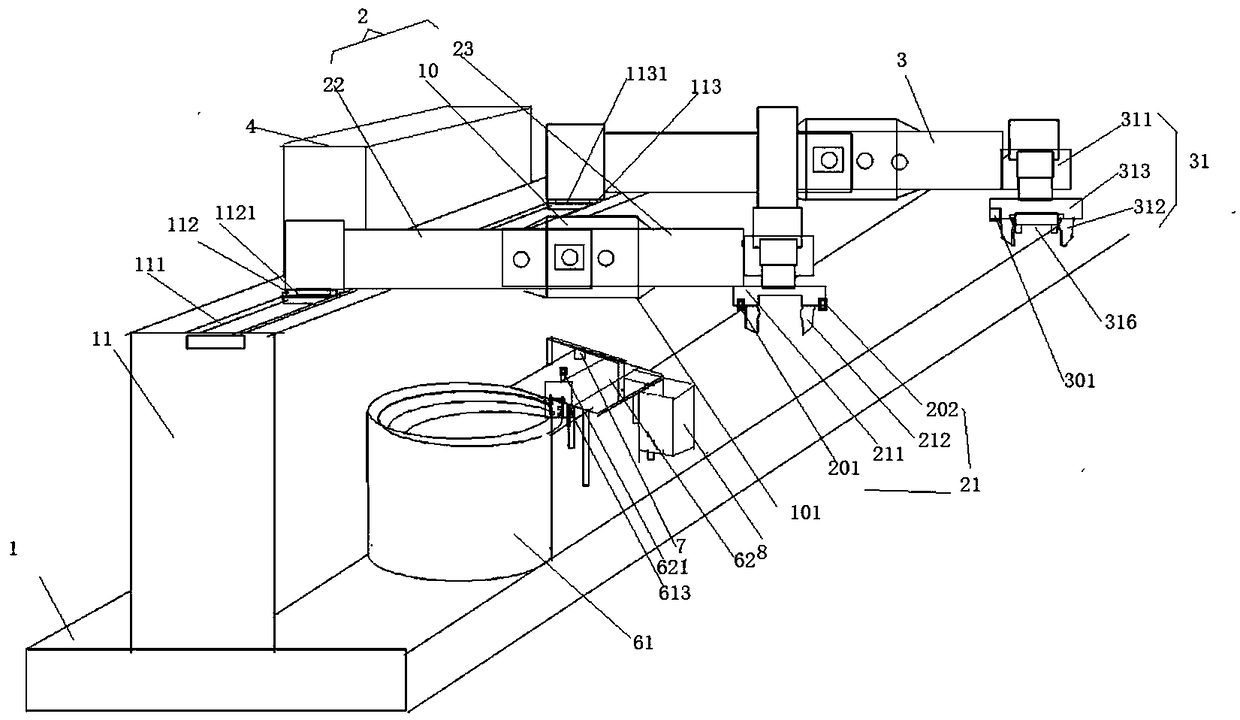

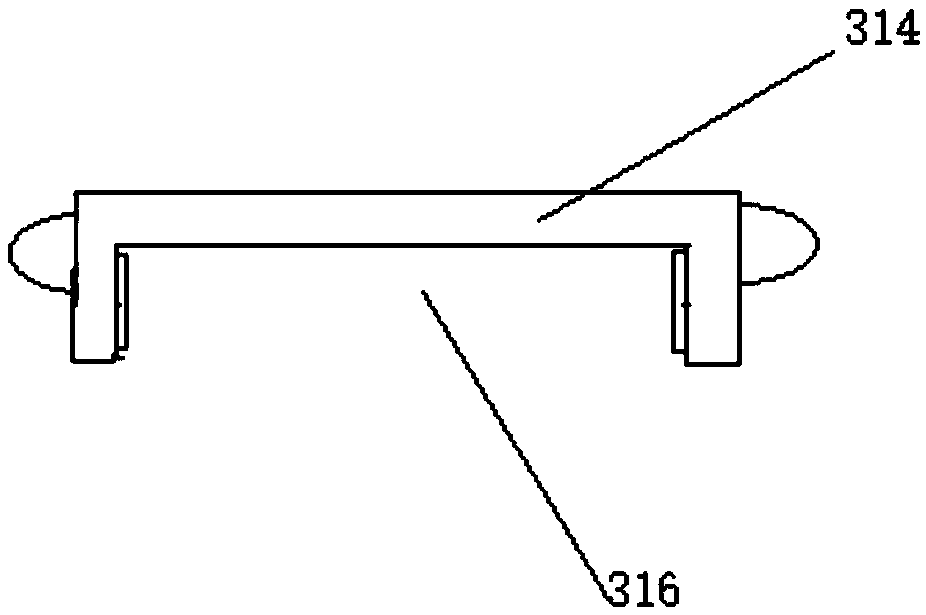

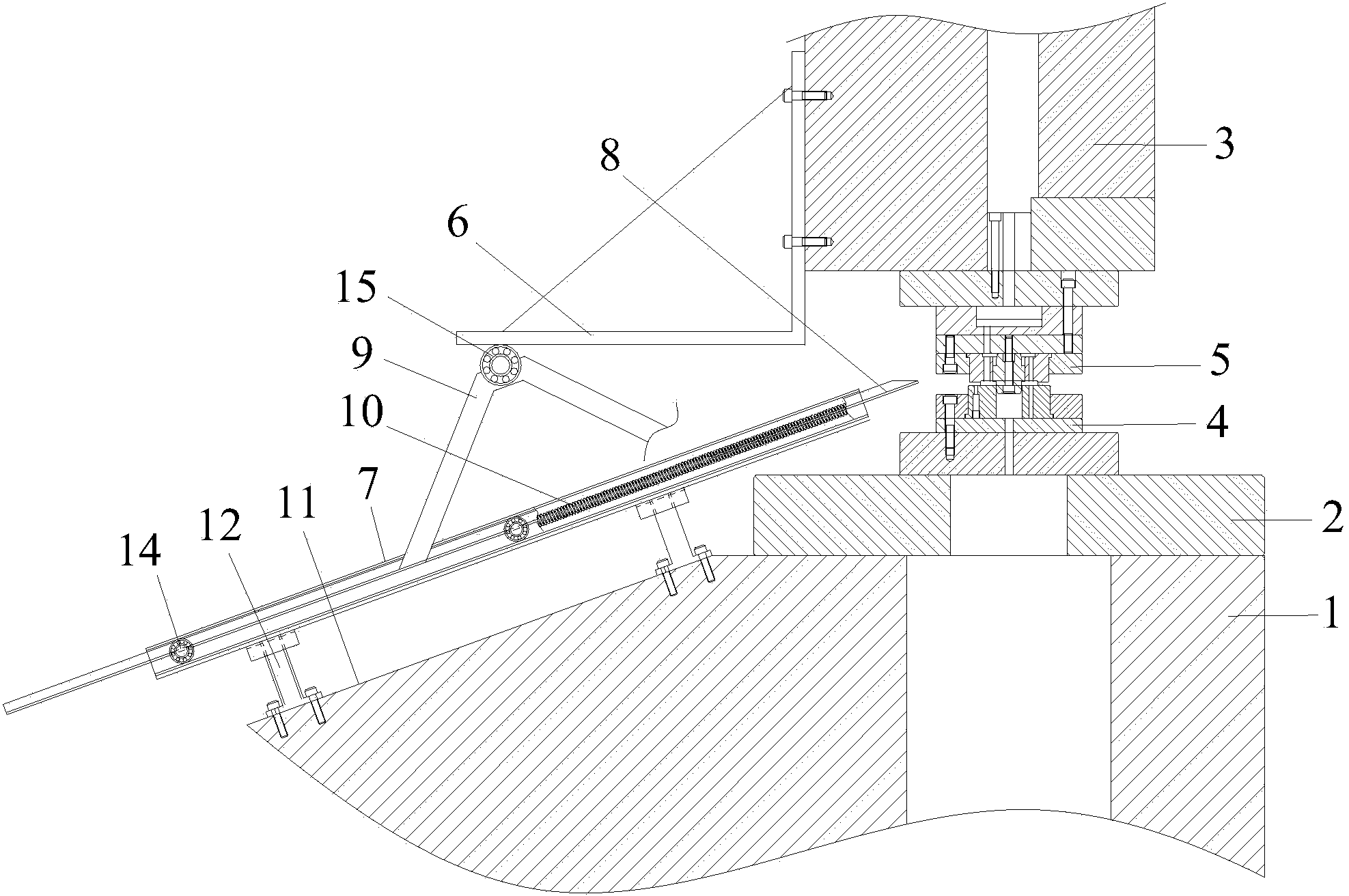

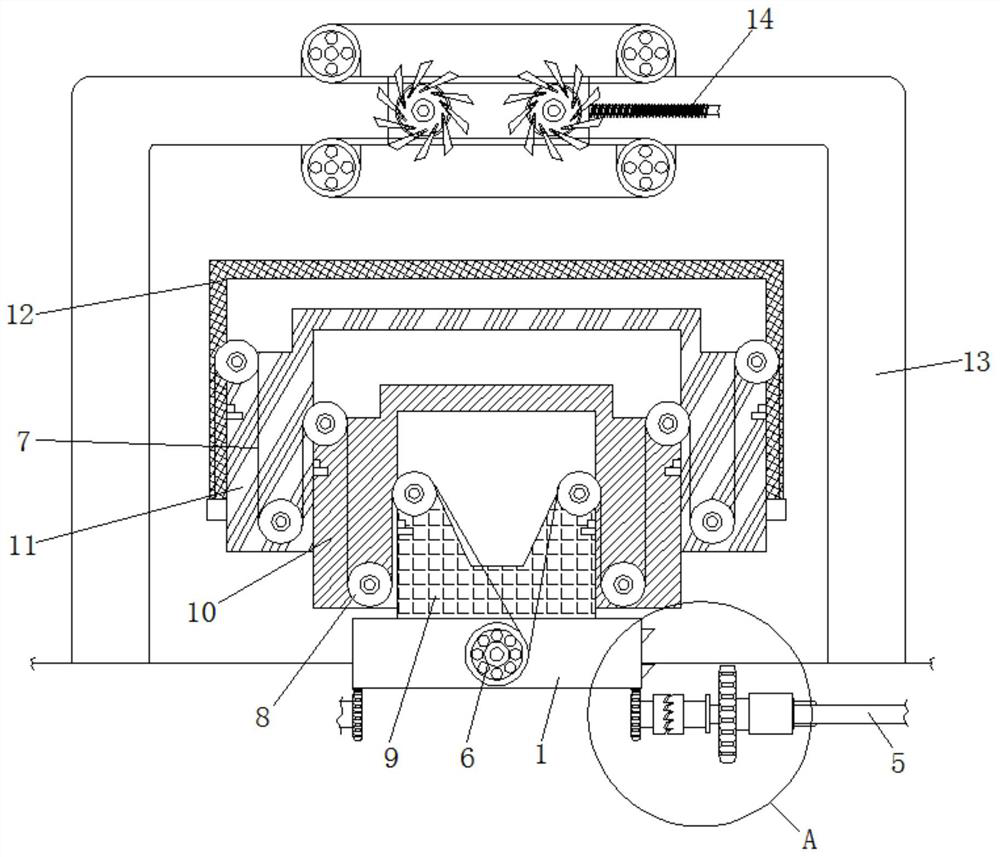

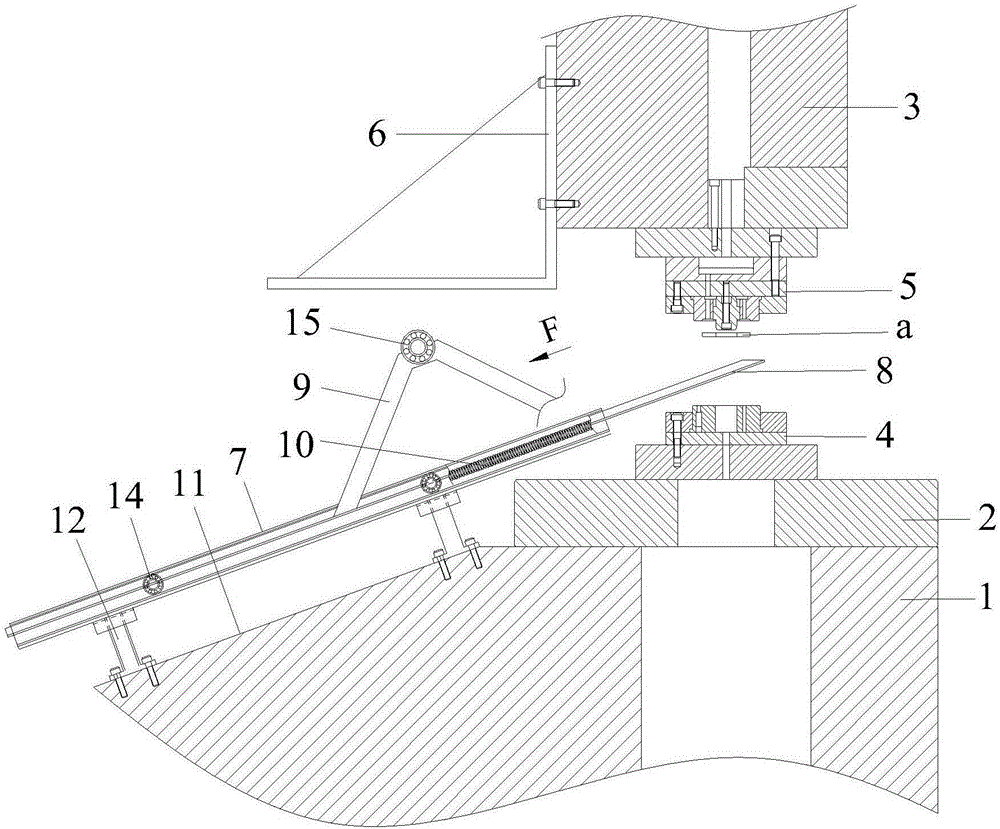

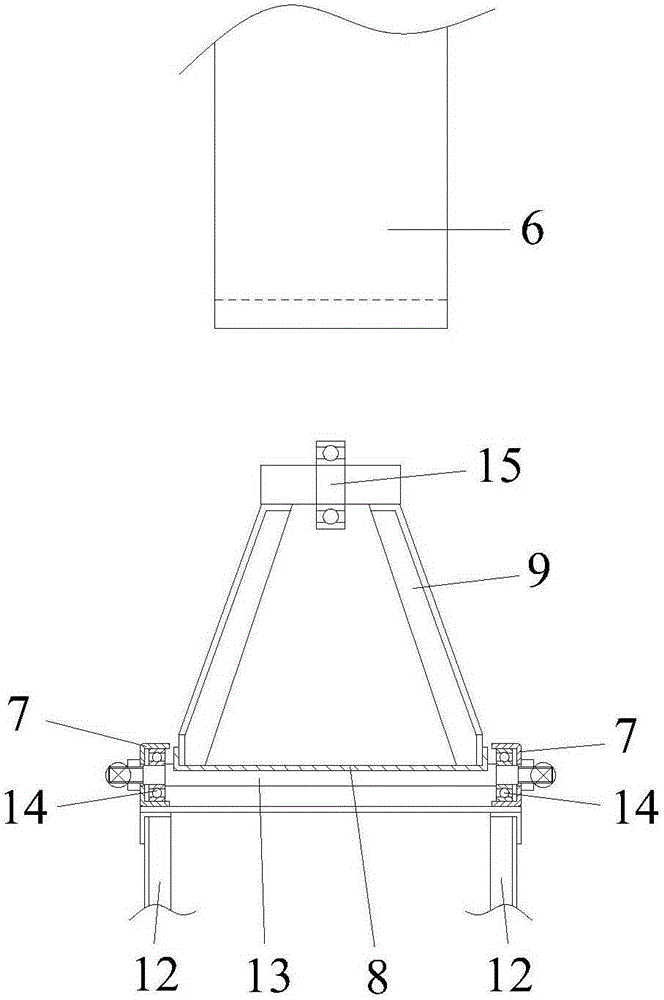

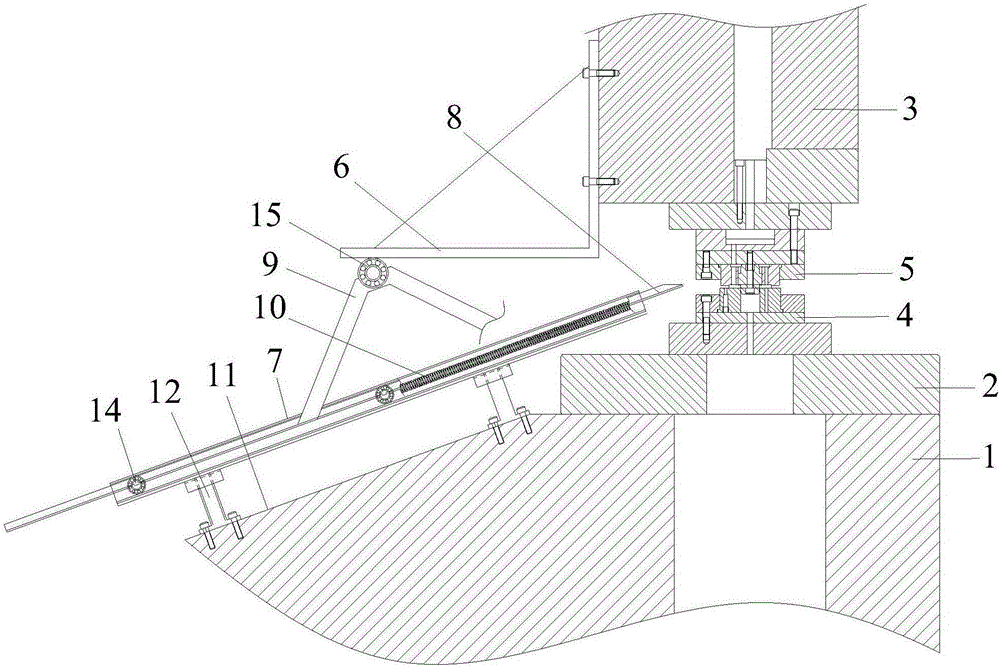

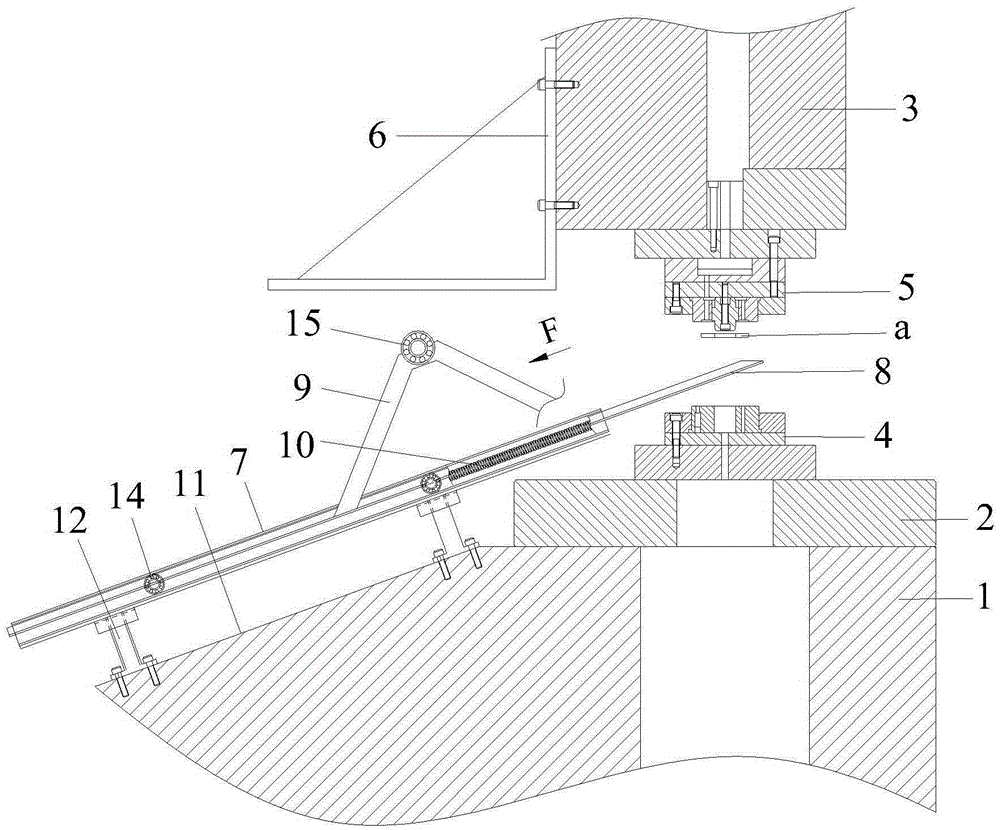

Energy-saving environment-friendly type smelting furnace

ActiveCN102679728ASolve the problem of manual feedingAvoid explosionCrucible furnacesLead smeltingEngineering

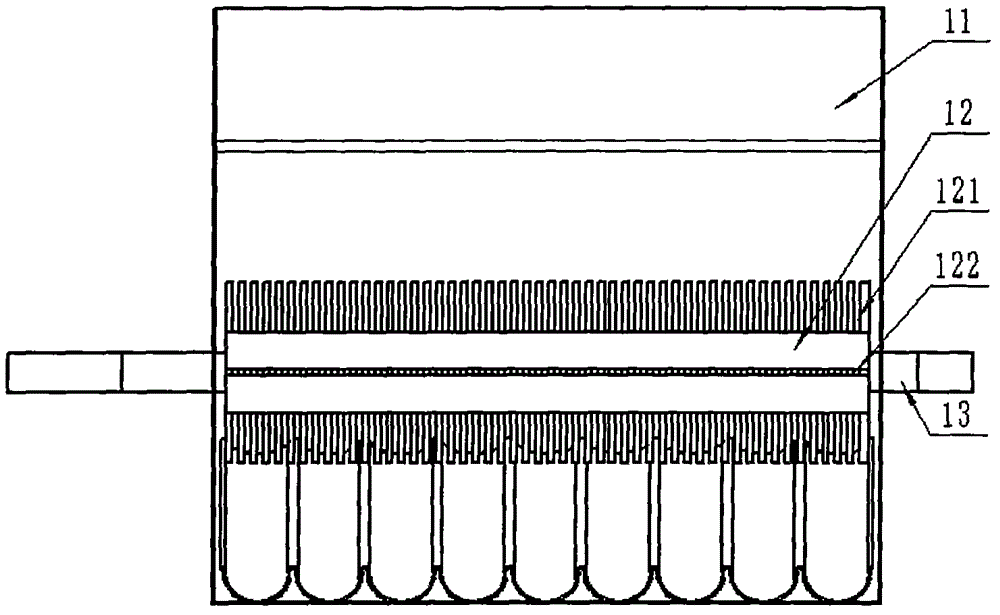

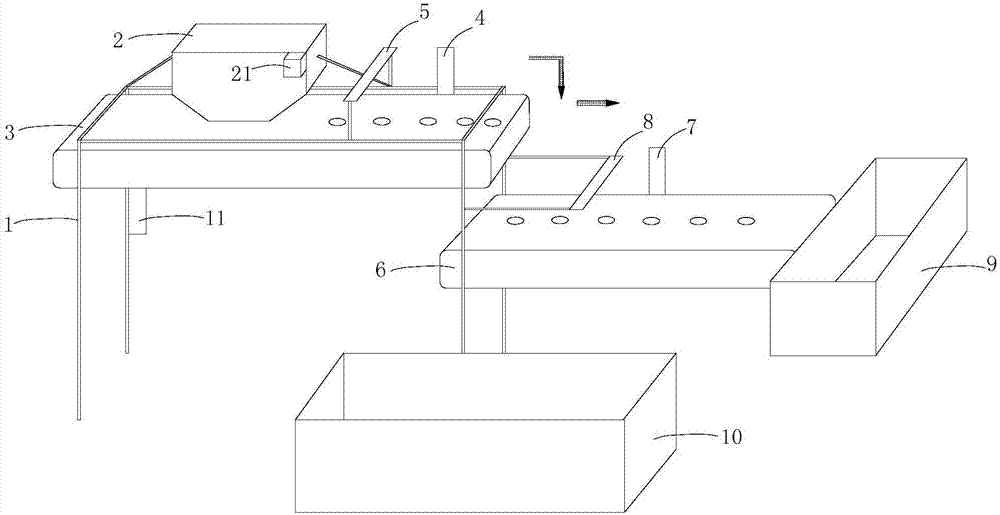

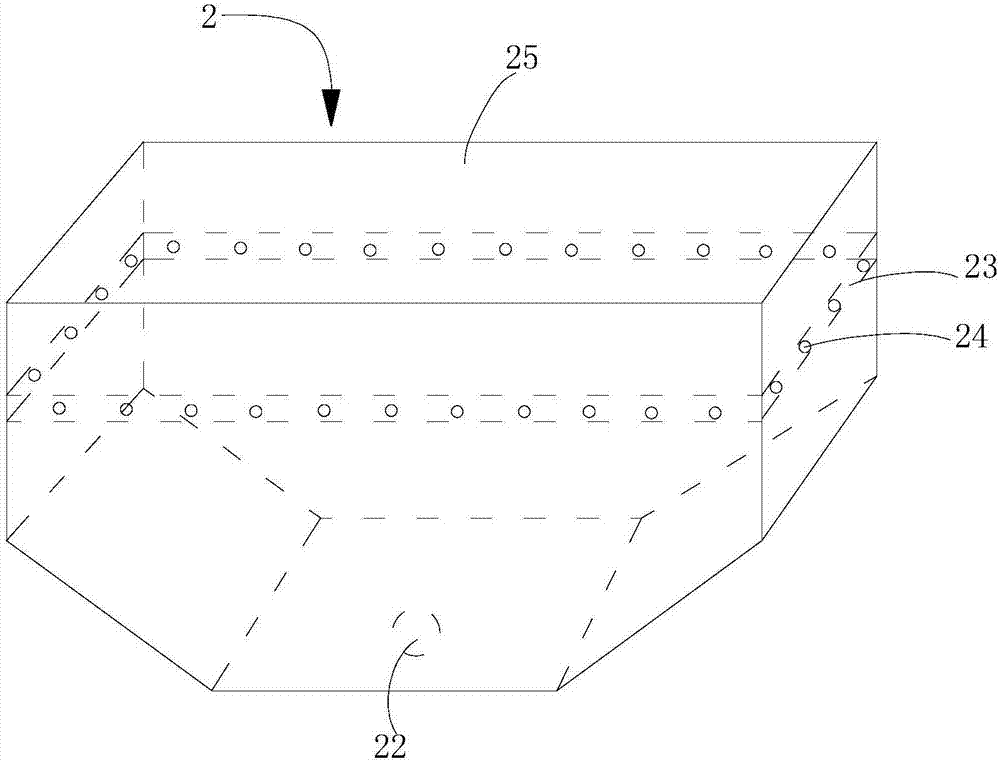

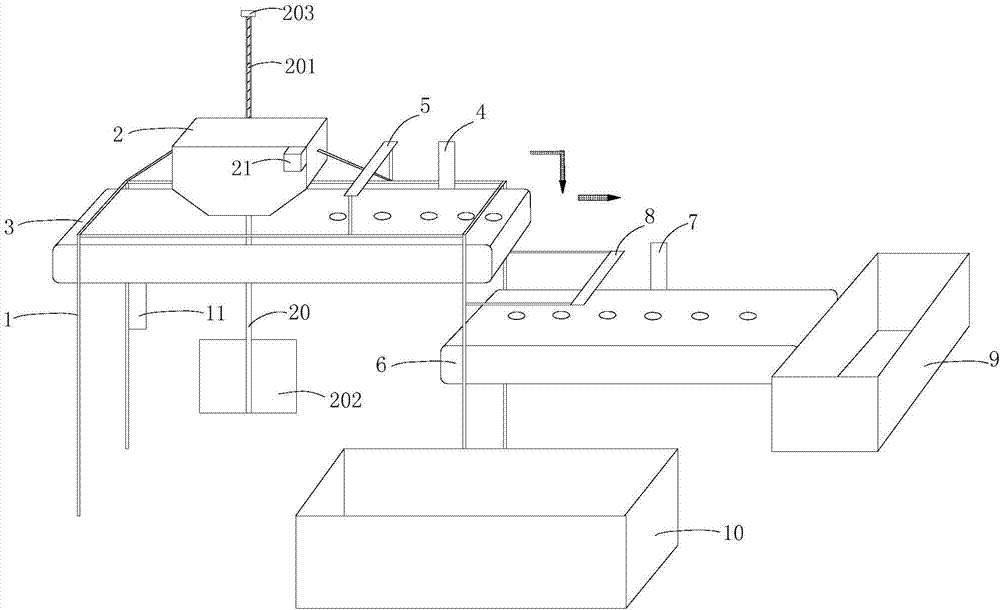

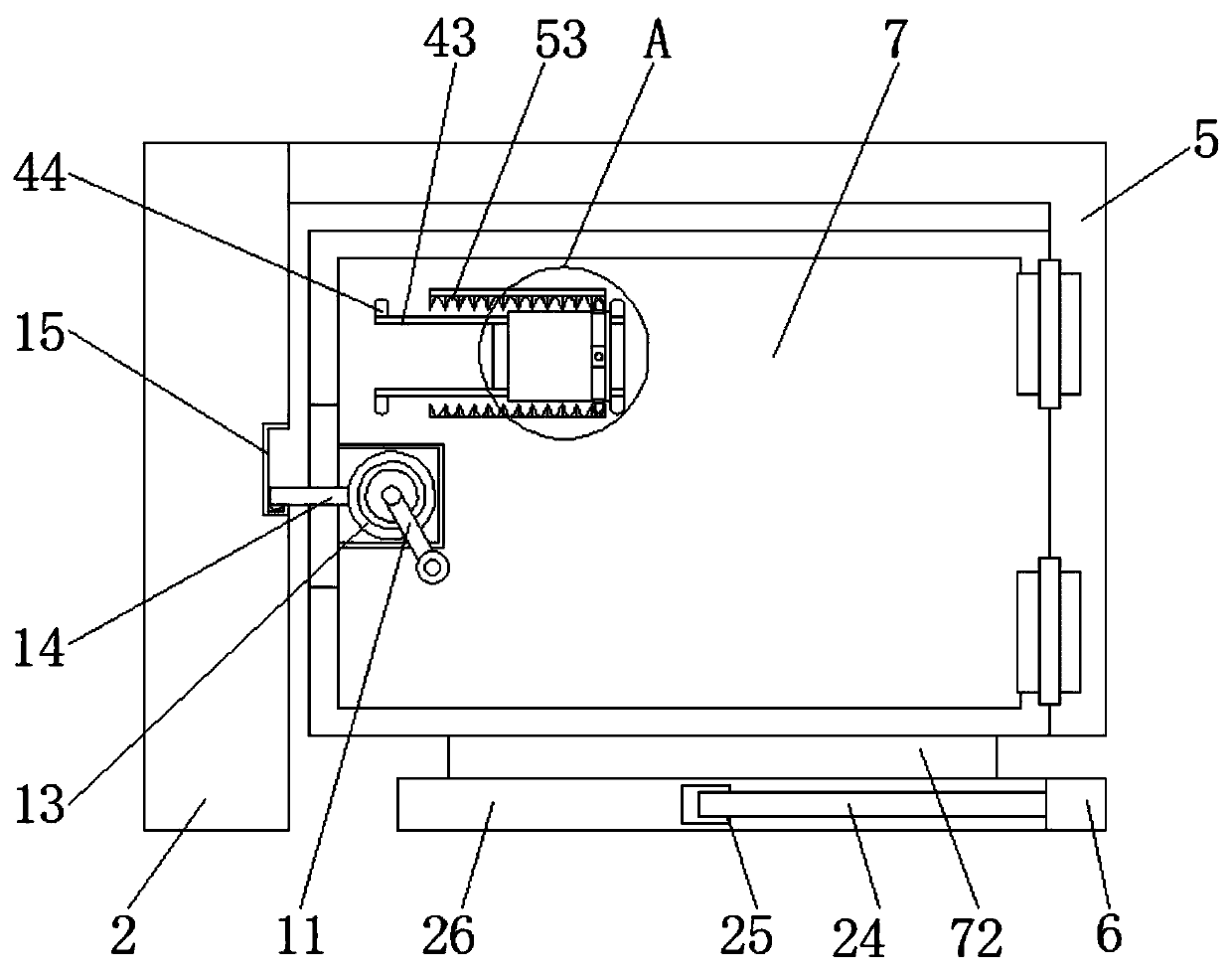

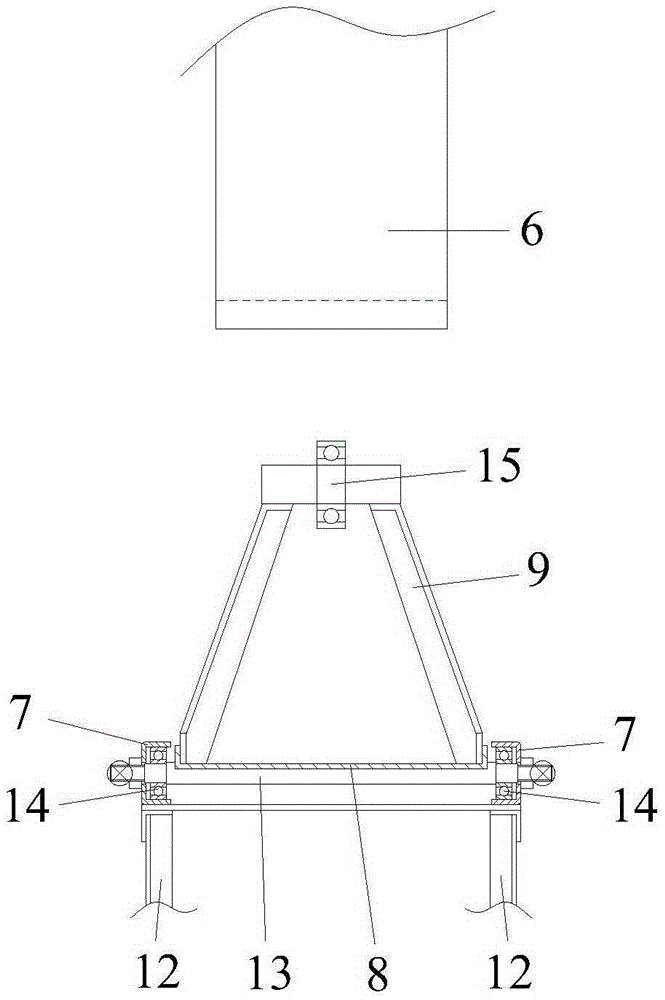

The invention discloses an energy-saving environment-friendly type smelting furnace, belonging to the field of lead recycling equipment. The smelting furnace comprises a heat supply smelting system, a feeding system, a discharging system, and a waste gas and smoke dust collecting system, wherein the heat supply smelting system comprises a bracket, a smelting chamber, a heating device and a lead smelting pot; the feeding system is formed by a feeding cabin rail and a feeding cabin which is slidingly arranged on the feeding cabin rail; the discharging system is arranged below a discharging opening of the smelting chamber of the heat supply smelting system and corresponds to the discharging opening; the waste gas and smoke dust collecting system comprises an upper dust removing chamber and a lower dust removing chamber; the upper dust removing chamber is arranged above the smelting chamber of the heat supply smelting system and is communicated with the feeding system; the upper dust removing chamber is communicated with a waste gas collecting pipeline through a pipeline; the lower dust removing chamber is arranged below the smelting chamber of the heat supply smelting system and is communicated with the discharging system; and the lower dust removing chamber is communicated with the waste gas collecting pipeline through a pipeline. The smelting furnace has the advantages of simple structure, energy saving and good environment-friendly performance.

Owner:ZHUZHOU DINGDUAN EQUIP CO LTD

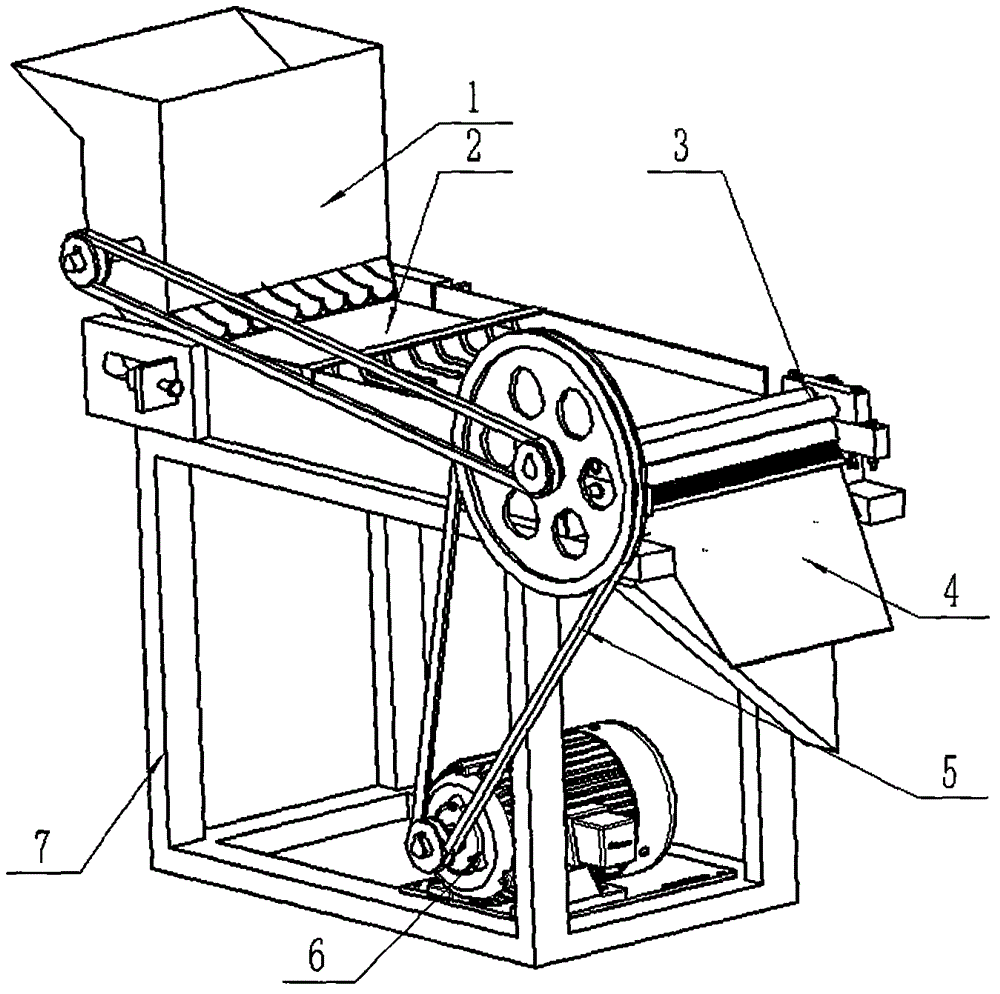

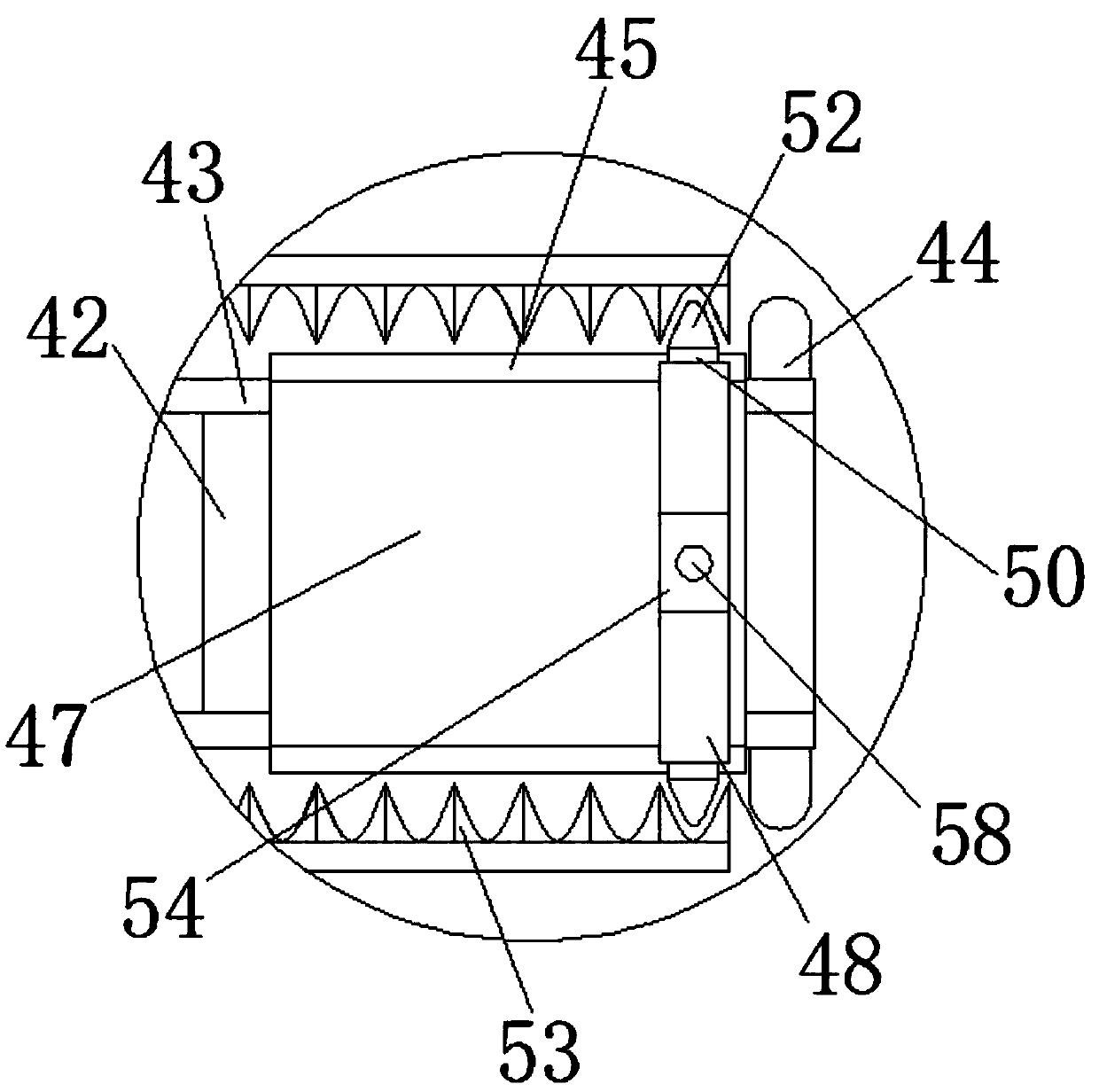

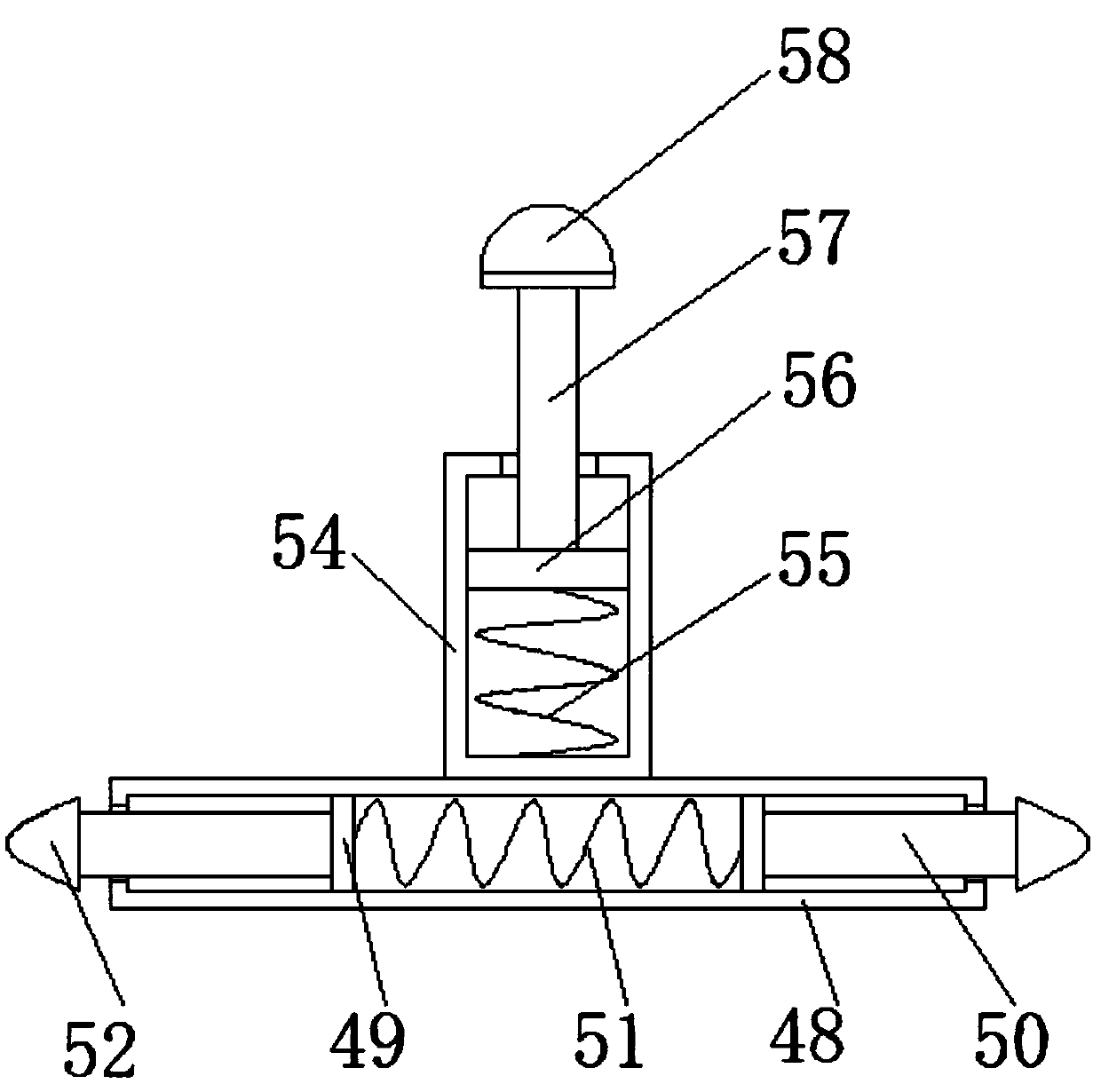

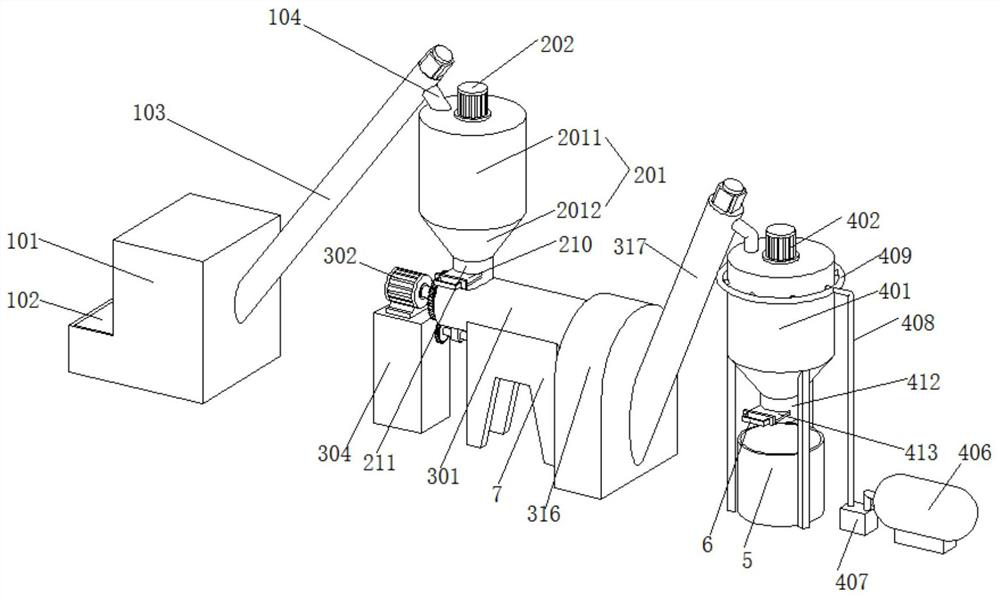

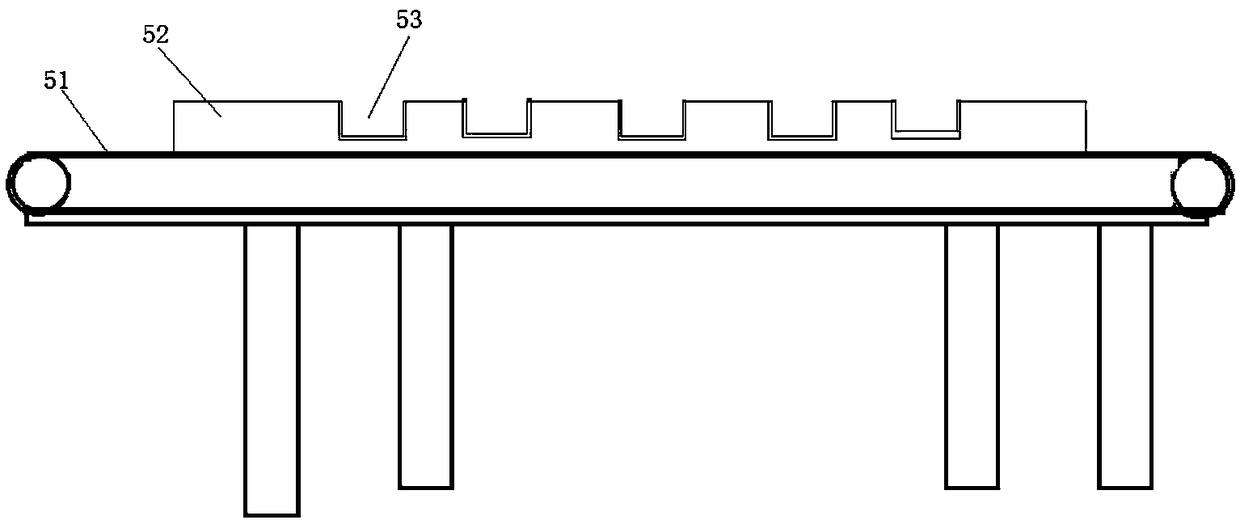

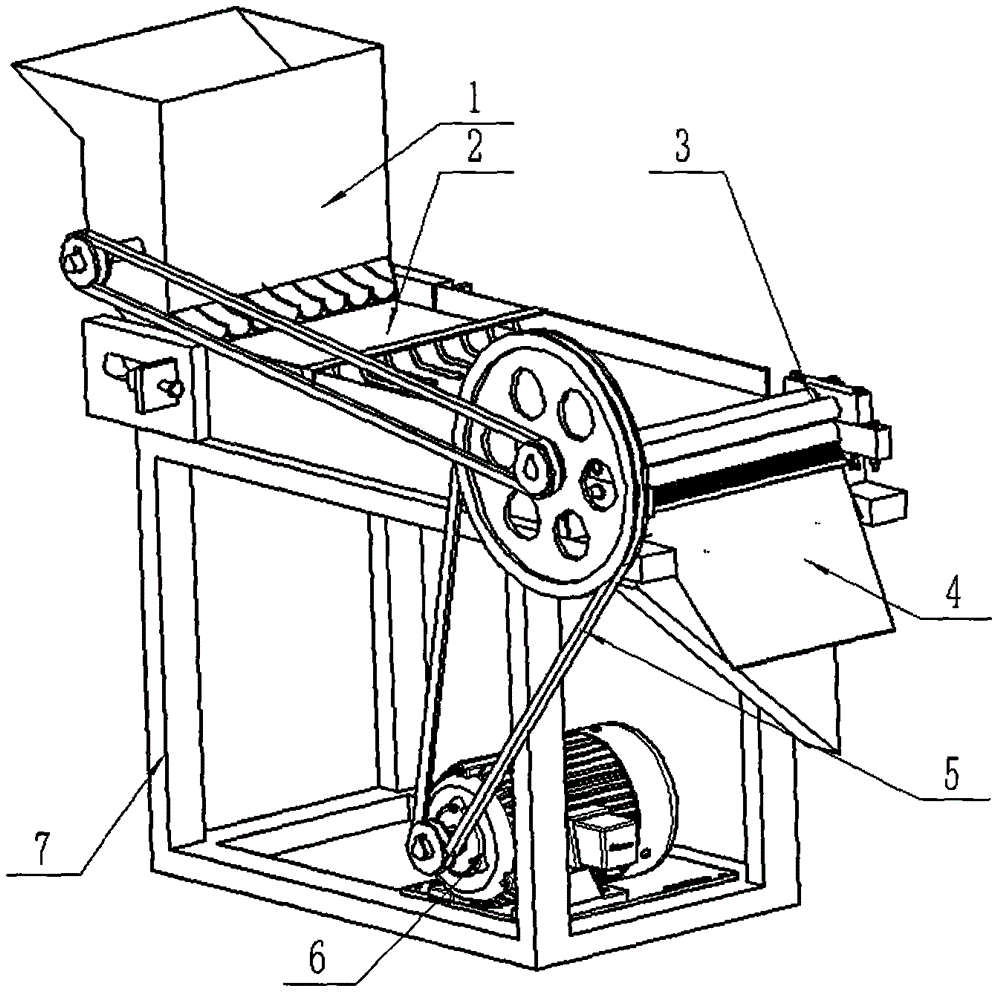

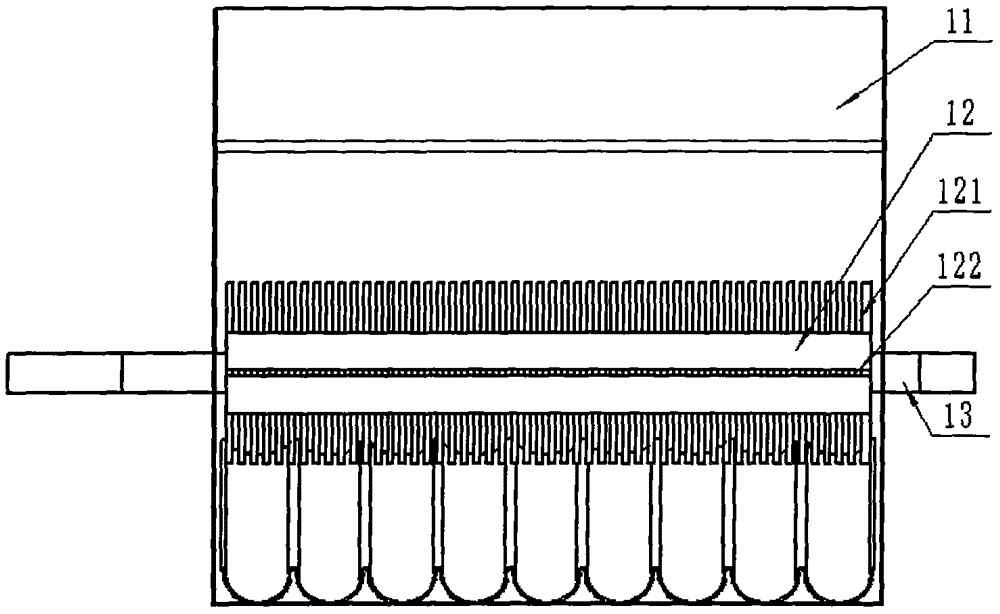

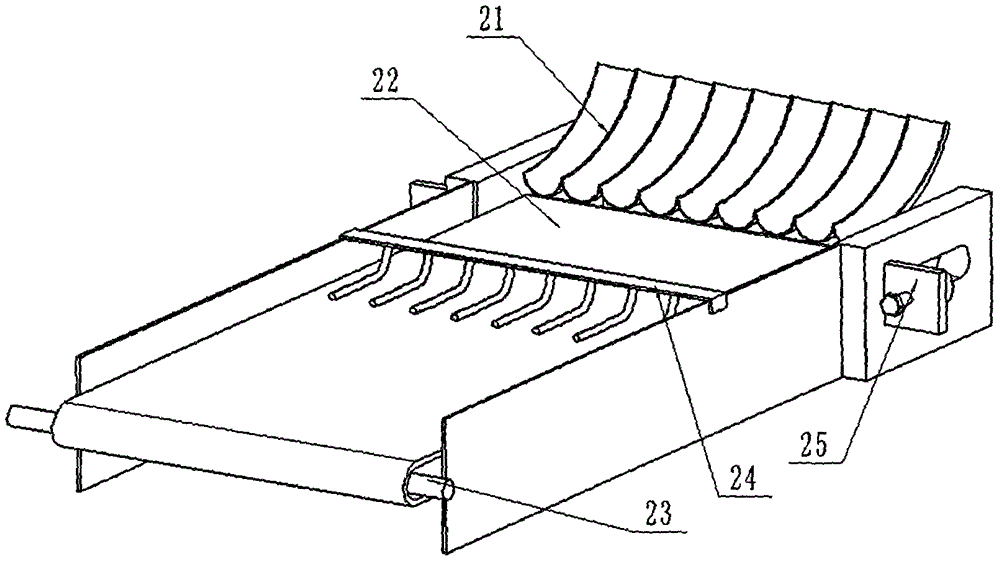

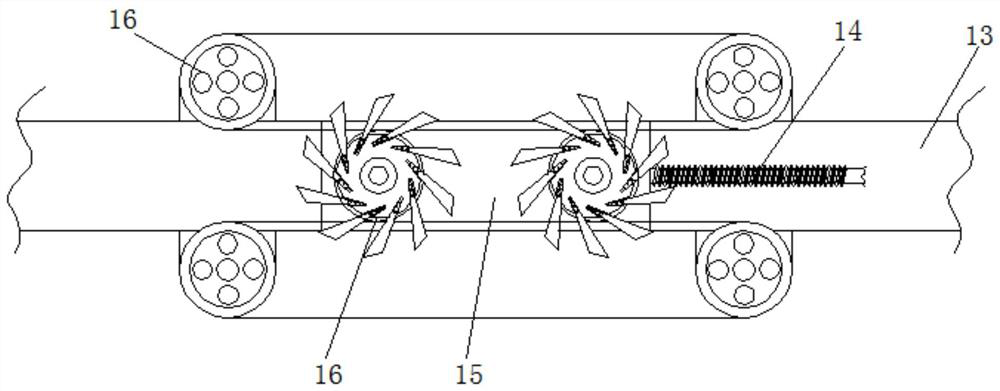

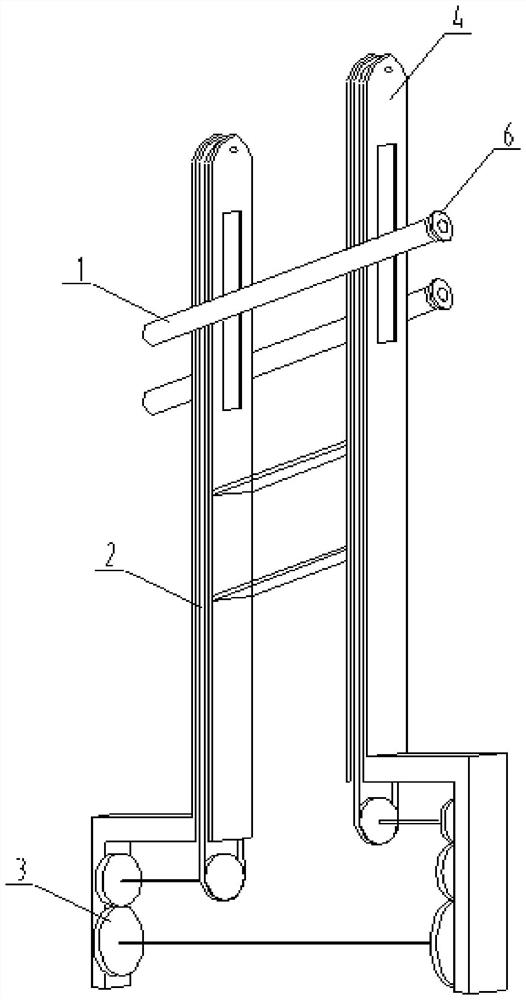

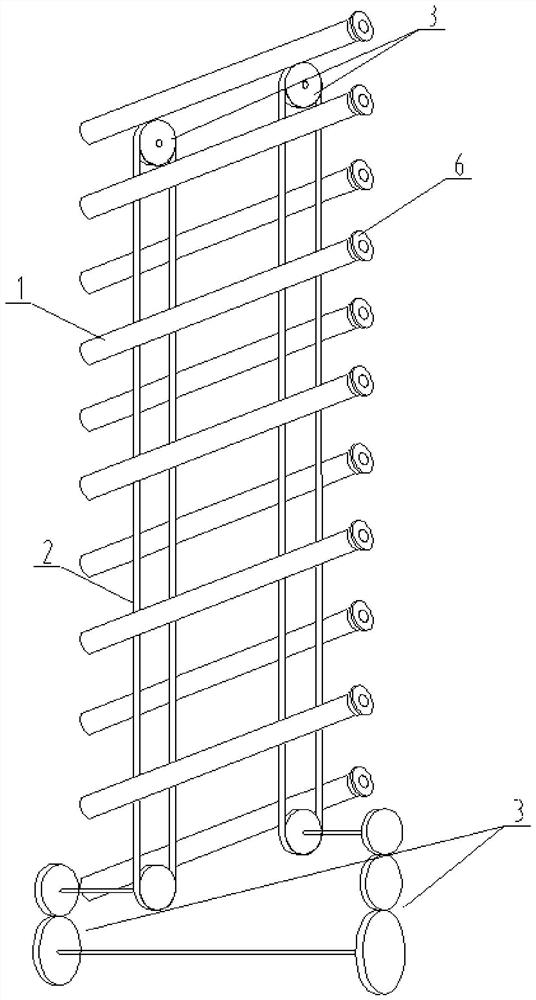

Energy-saving green soy bean husking machine capable of conducing automatic feeding and conveying

ActiveCN104544507ASolve the problem of manual feedingReduce power consumptionFood treatmentEngineeringConveyor belt

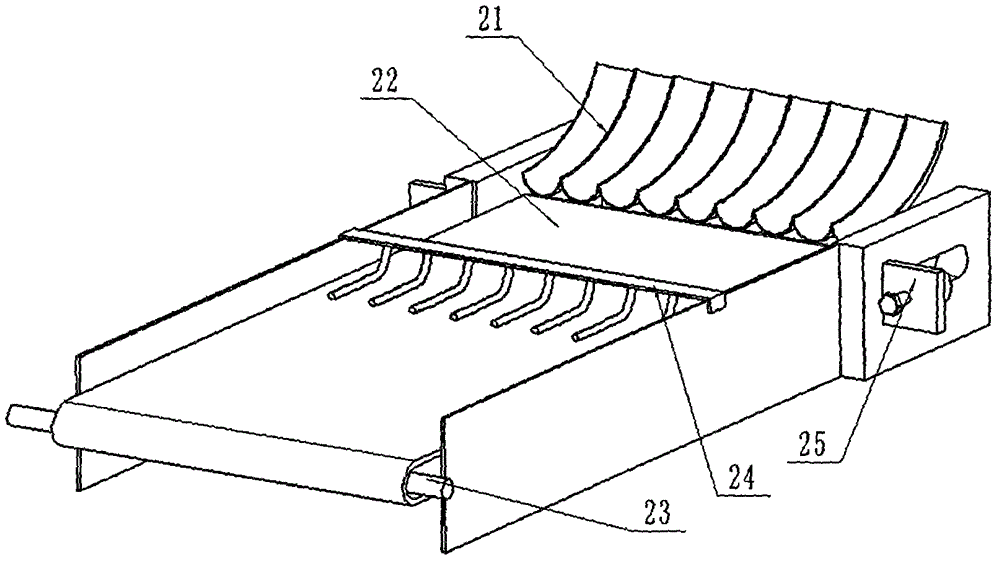

The invention provides an energy-saving green soy bean husking machine capable of conducing automatic feeding and conveying. The energy-saving green soy bean husking machine comprises a feeding device, a conveying device, a husking device, a collecting device, a transmission mechanism assembly and a driving device, wherein the husking device is installed on a machine frame, the conveying device is arranged on one side of the husking device, the collecting device is arranged on the other side of the husking device, the feeding device is arranged at one end of the conveying device, the driving device is arranged at the lower end of the machine frame, and the driving device is connected with and drives the husking device through the transmission mechanism assembly. Automation and high efficiency are achieved, effective effects are achieved, a vibrating screen is replaced with a feeding hopper, and the problem of the manual feeding of an existing green soy bean husking machine is solved; meanwhile, conveying is achieved through a conveyor belt, the problem that the existing green soy bean husking machine is low in husking efficiency is solved, vibration motors are reduced, and the machining and manufacturing cost of the green soy bean husking machine is reduced; in addition, a power mechanism is simplified, energy consumption mechanisms are reduced, the power consumption of the existing green soy bean husking machine is lowered, the collecting device is optimized, and husked green soy beans are cleaner and more sanitary.

Owner:ANHUI AGRICULTURAL UNIVERSITY

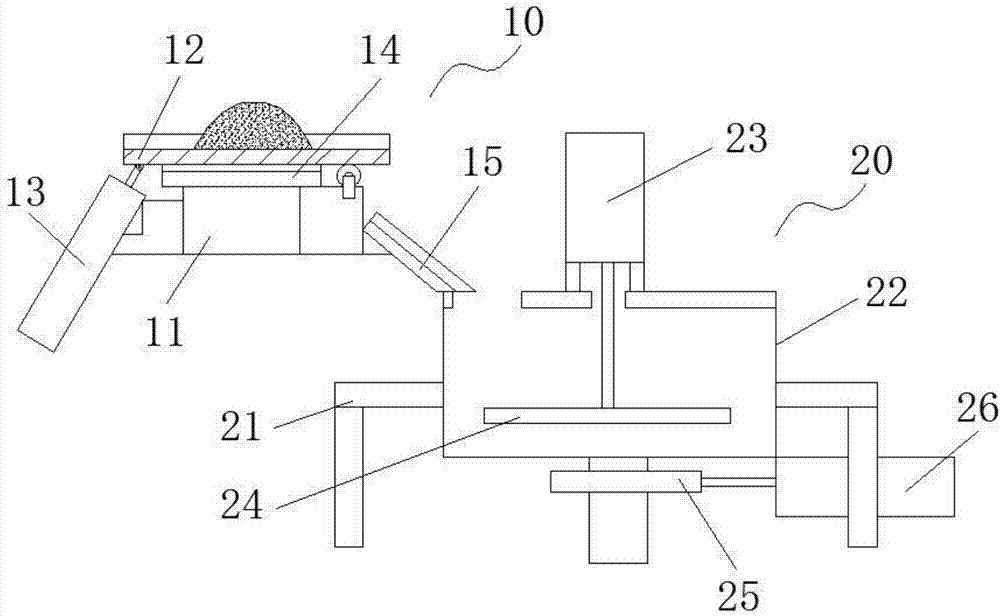

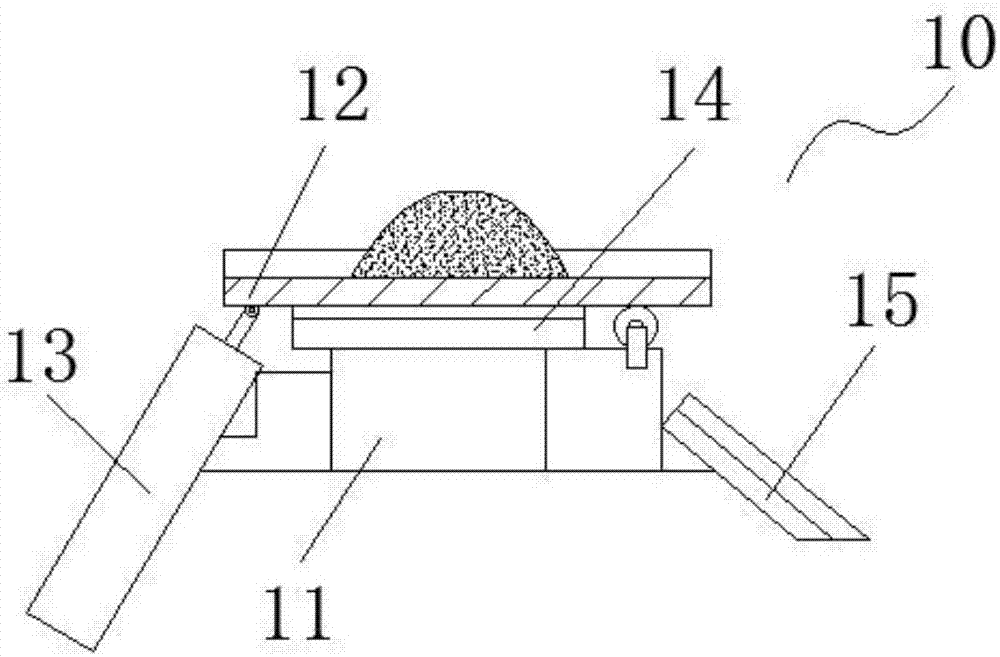

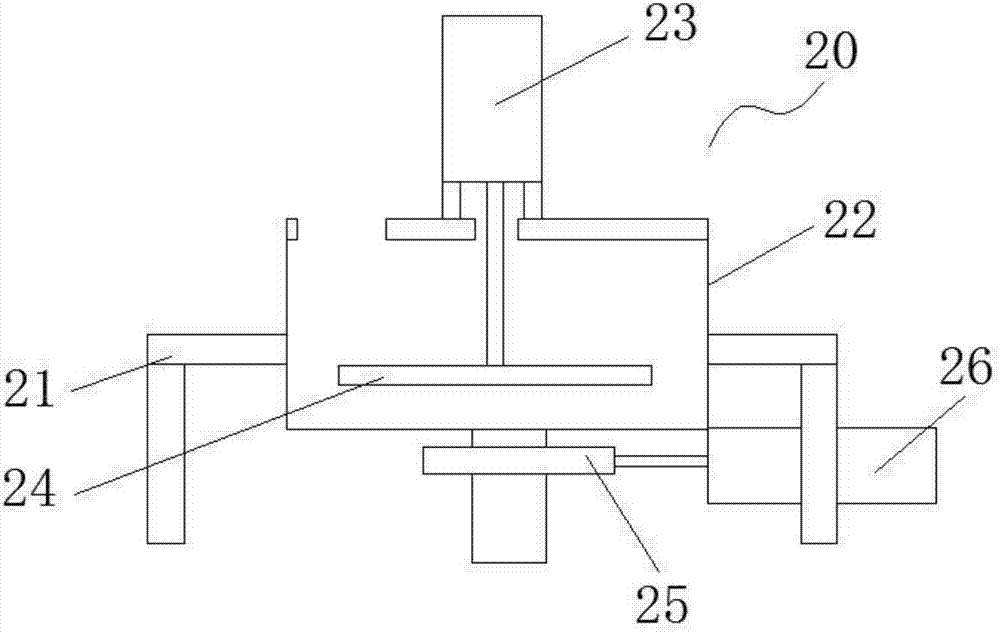

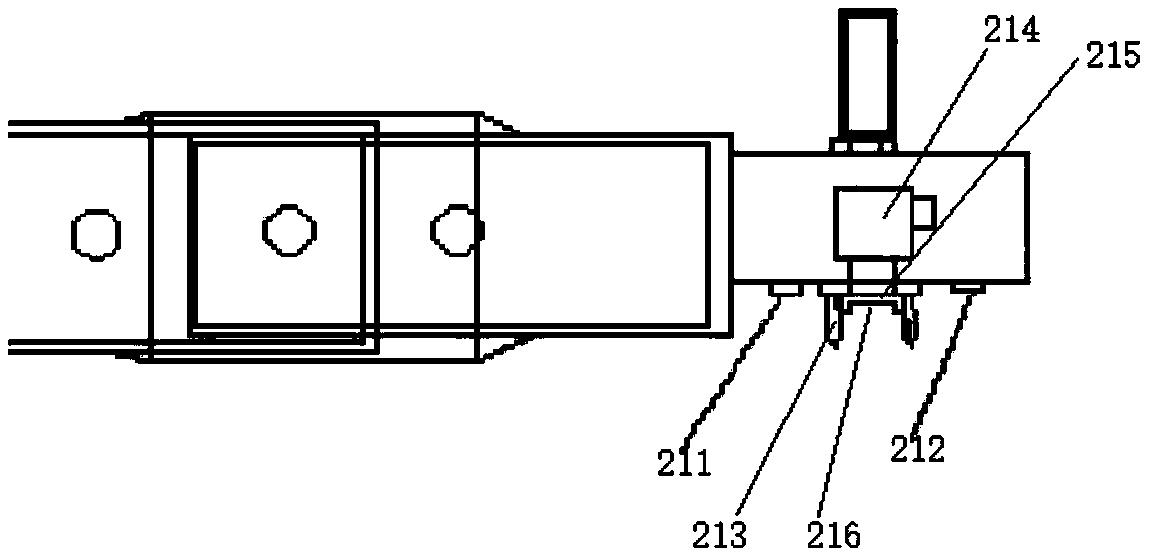

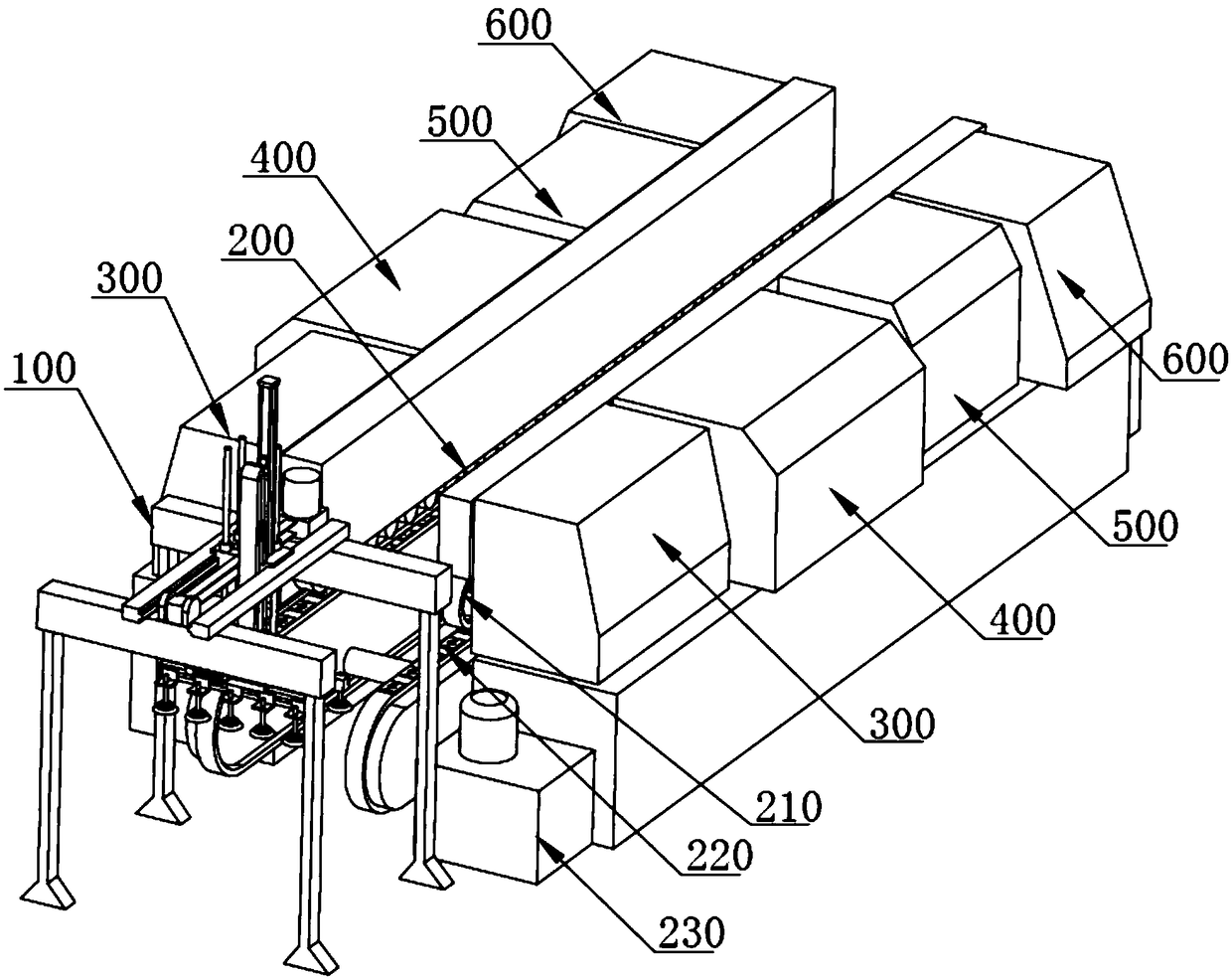

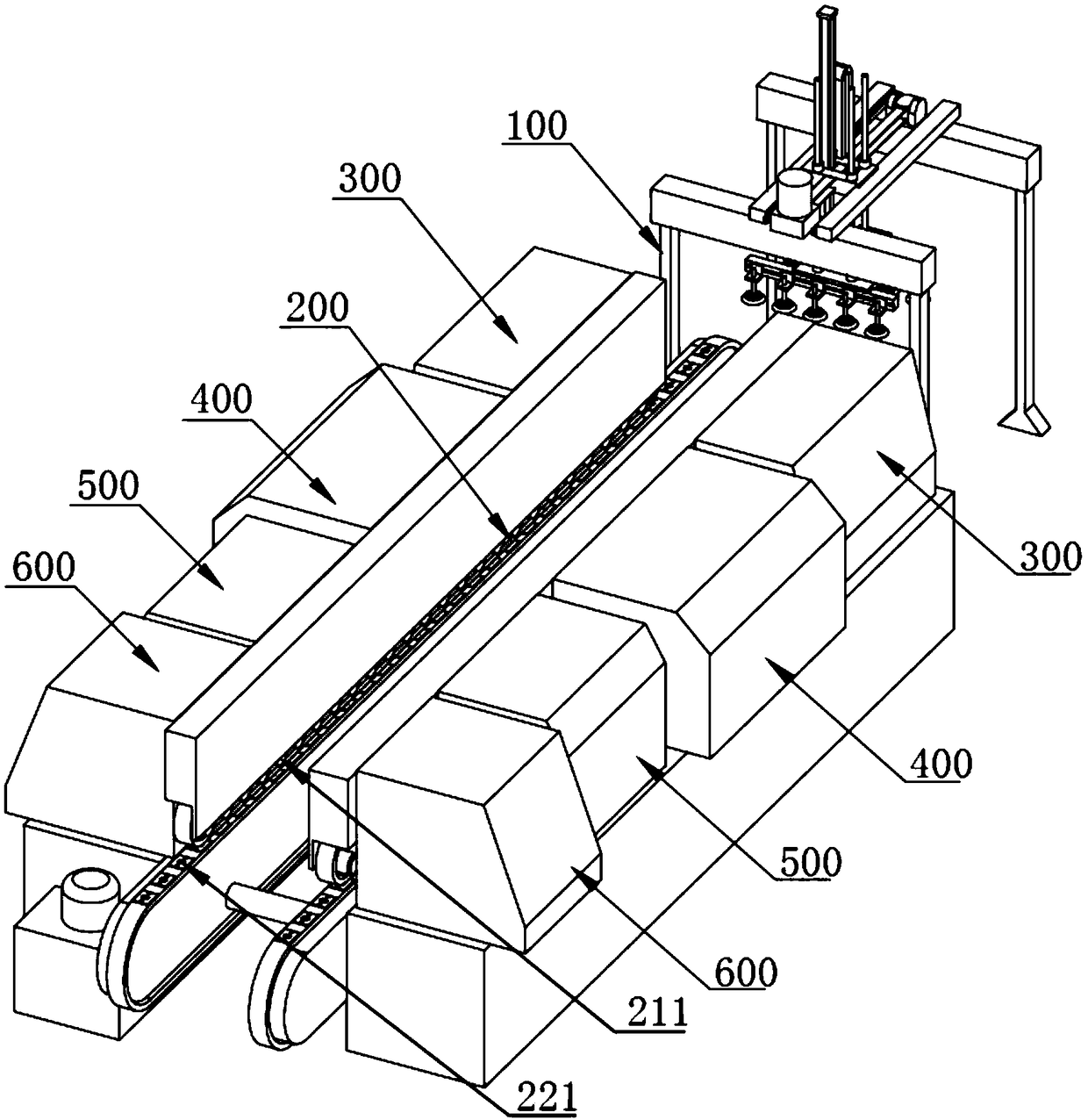

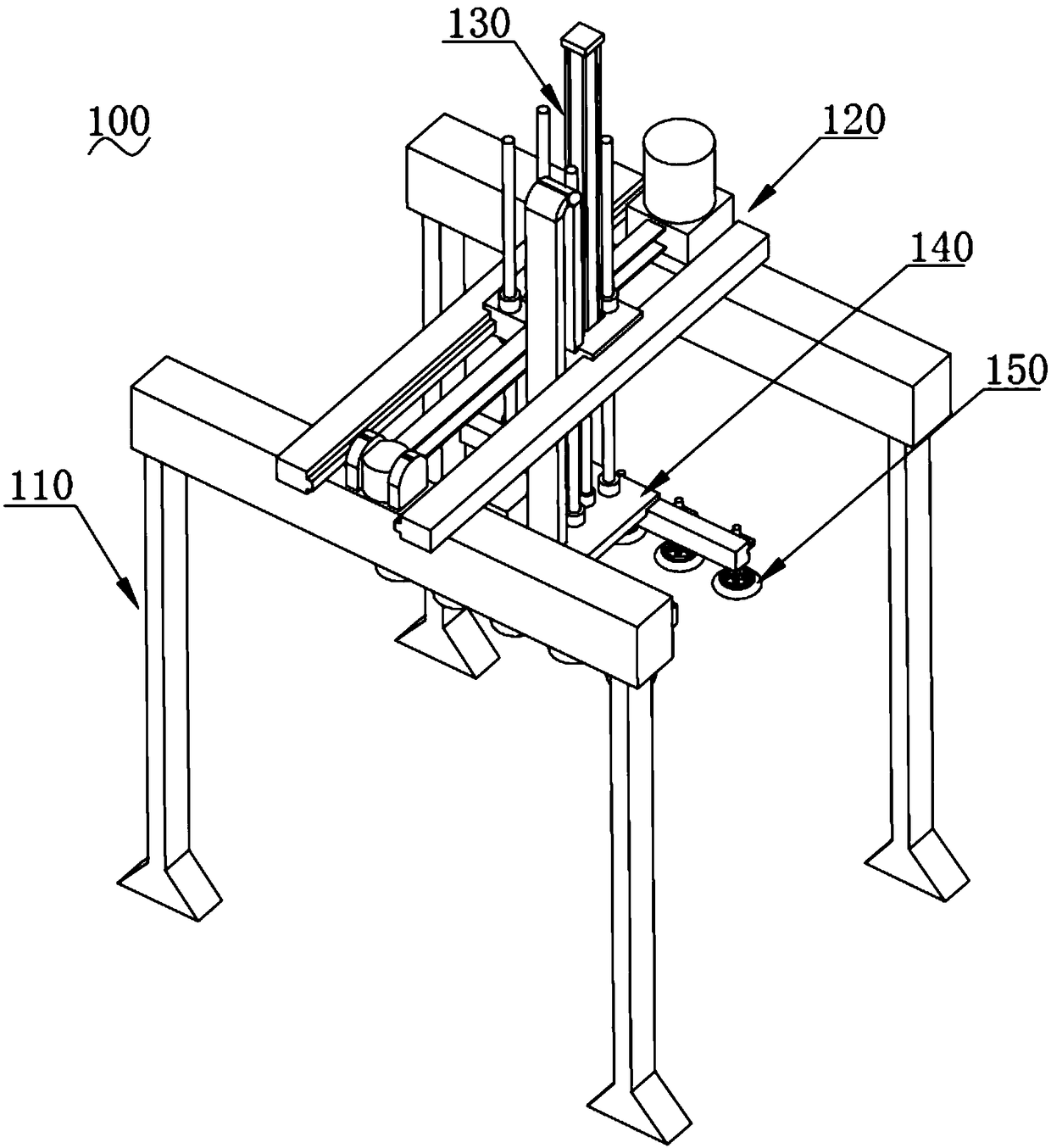

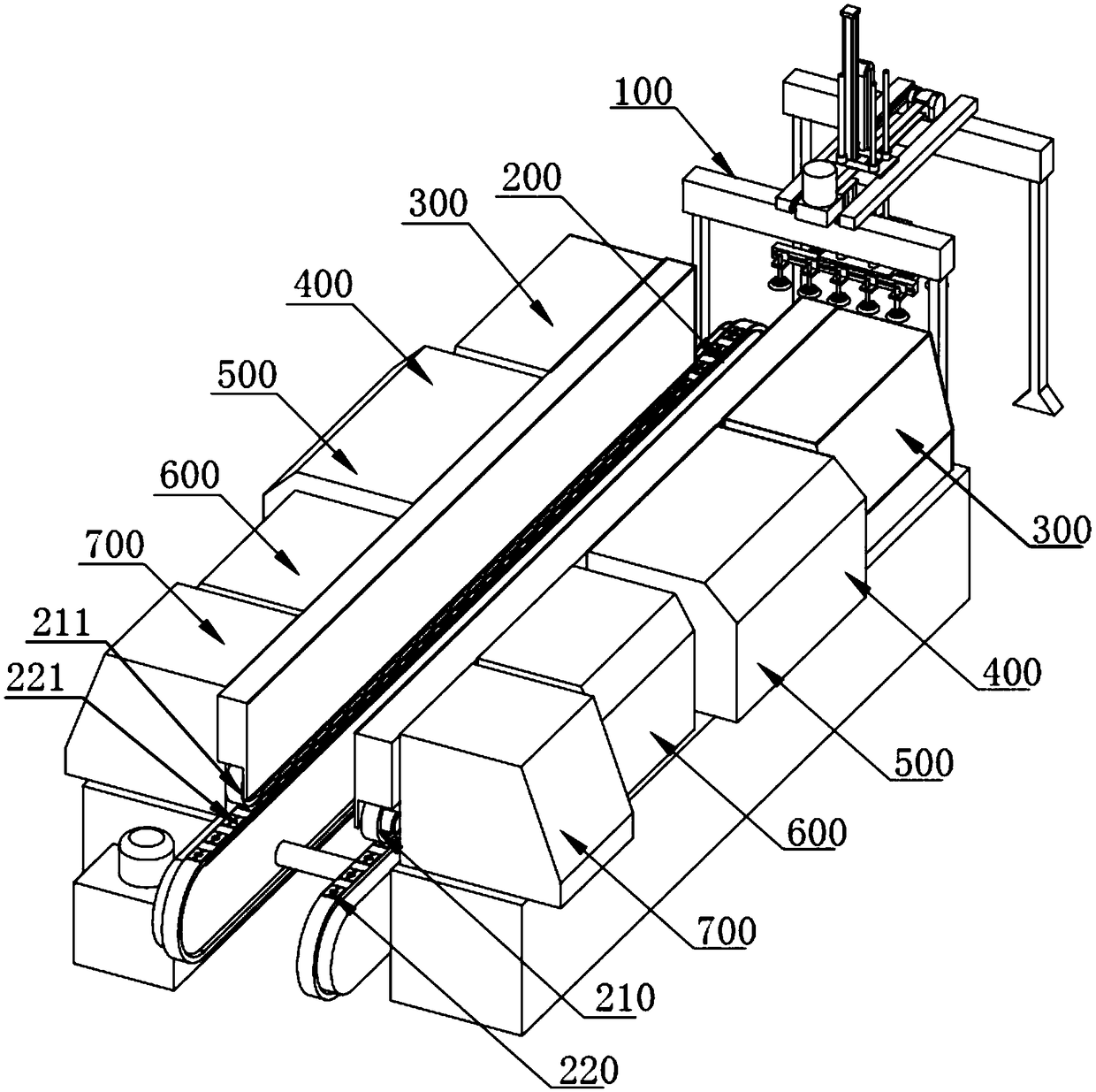

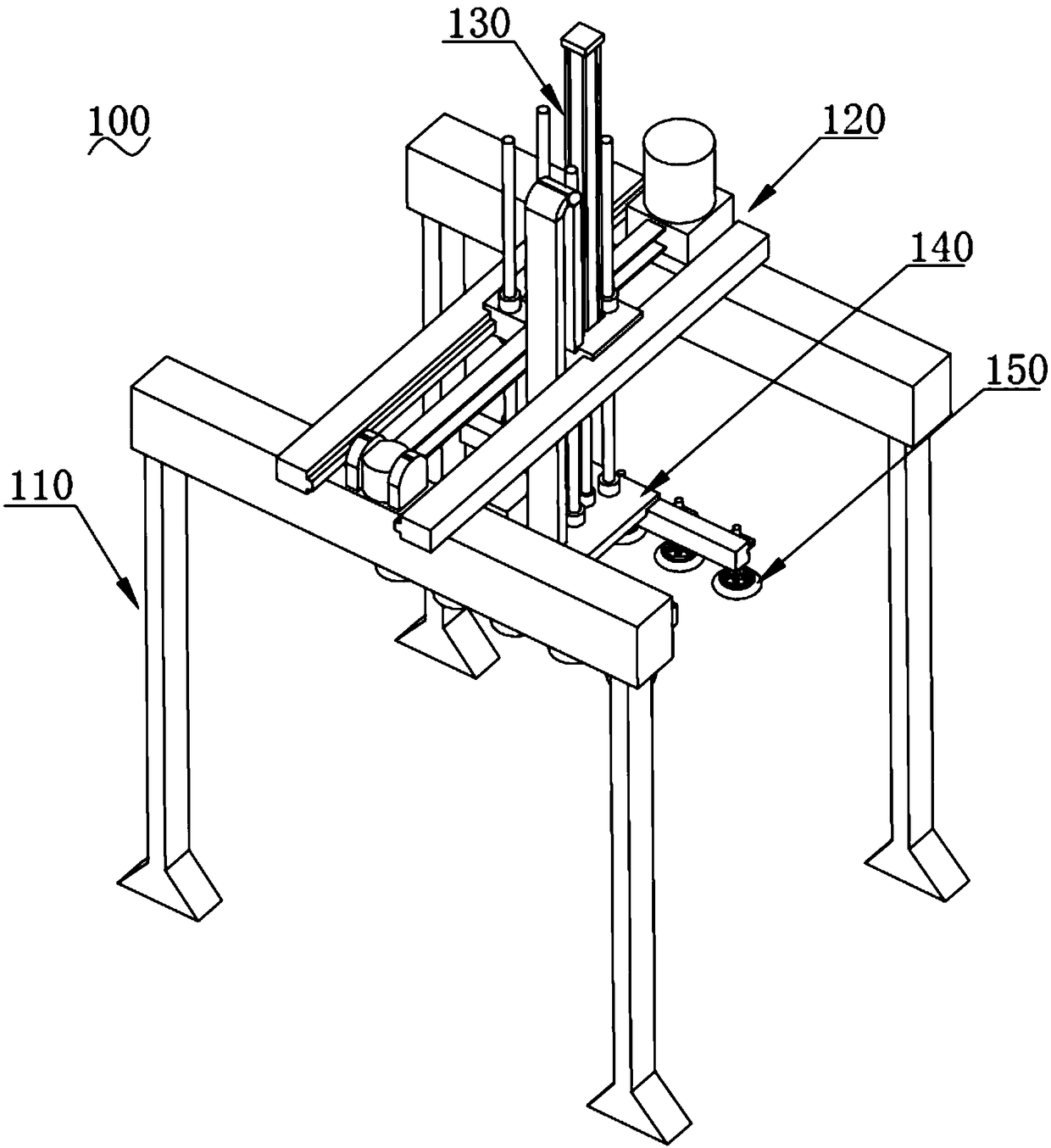

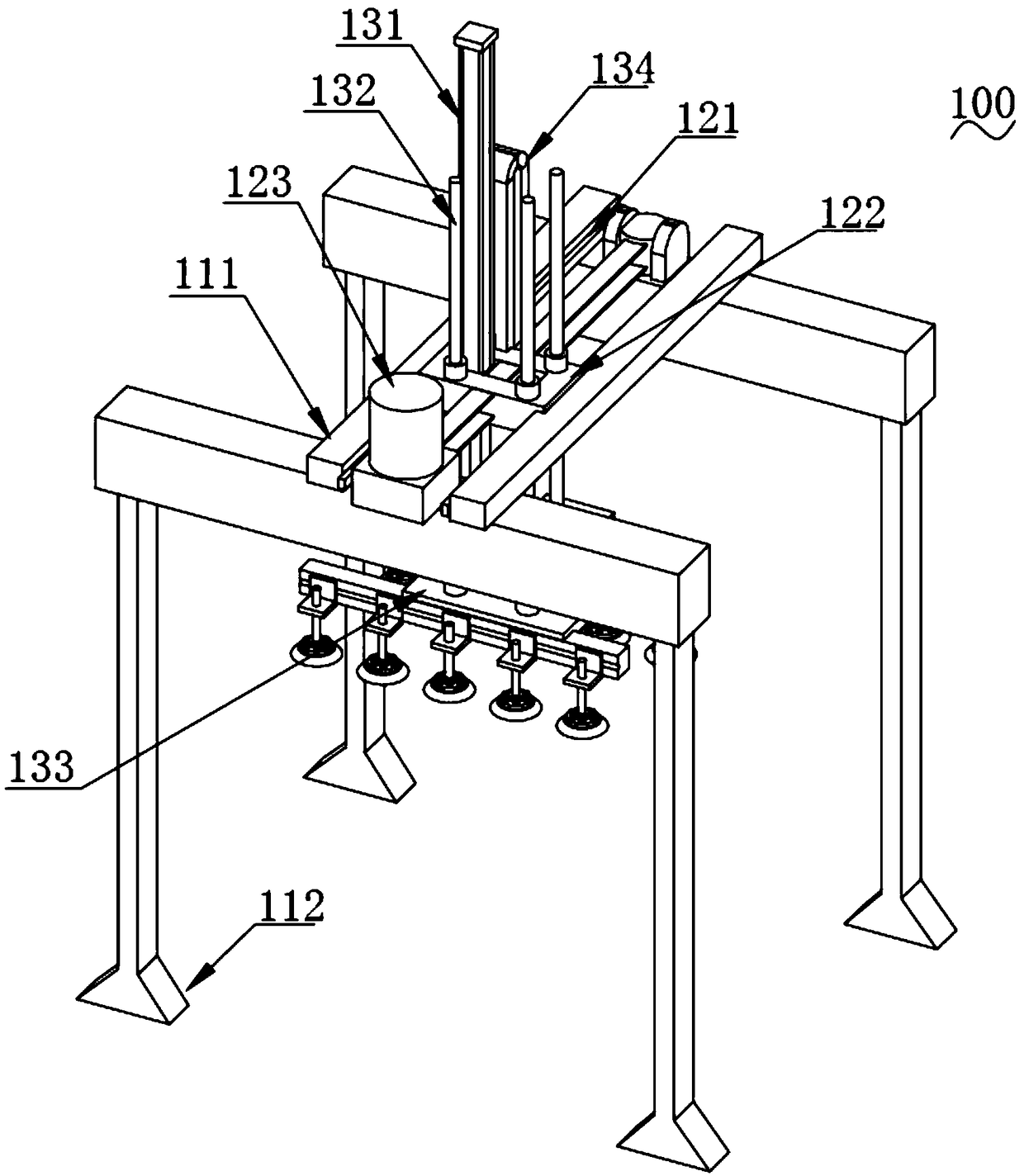

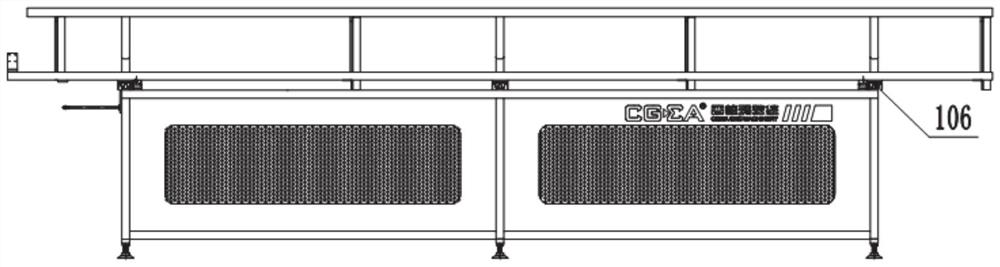

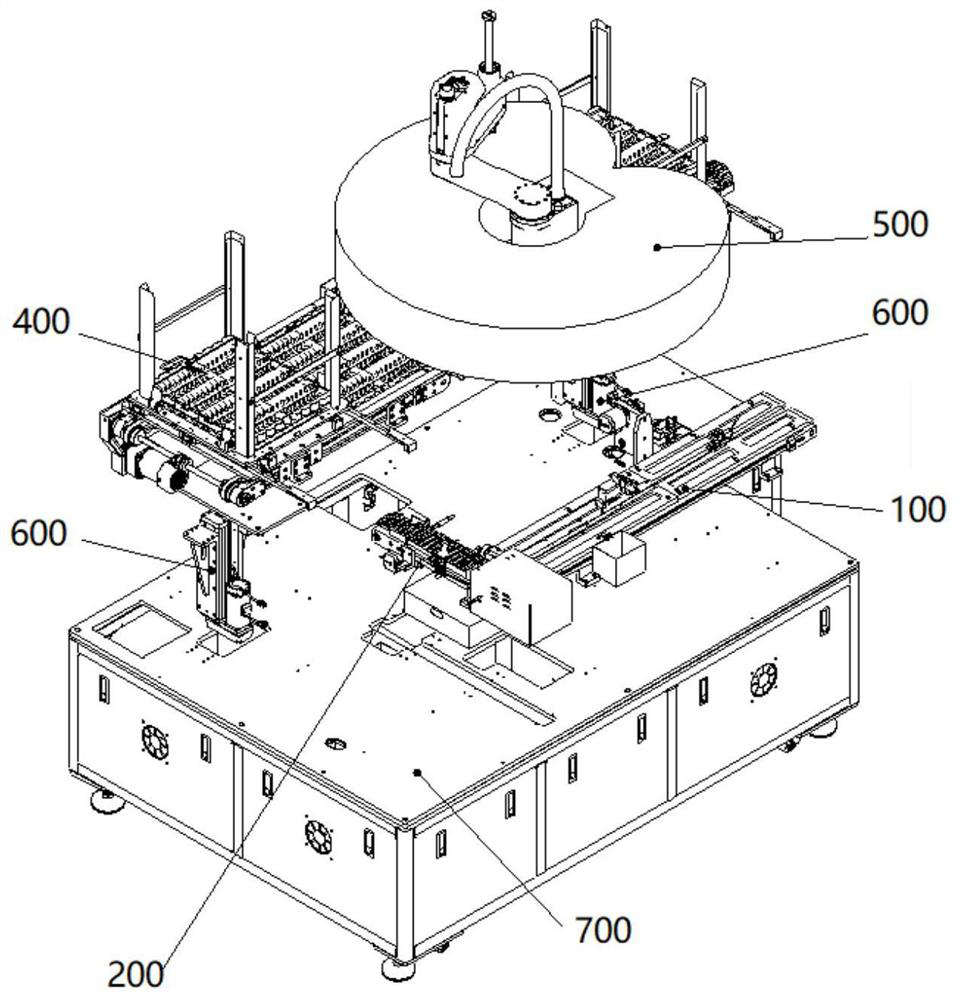

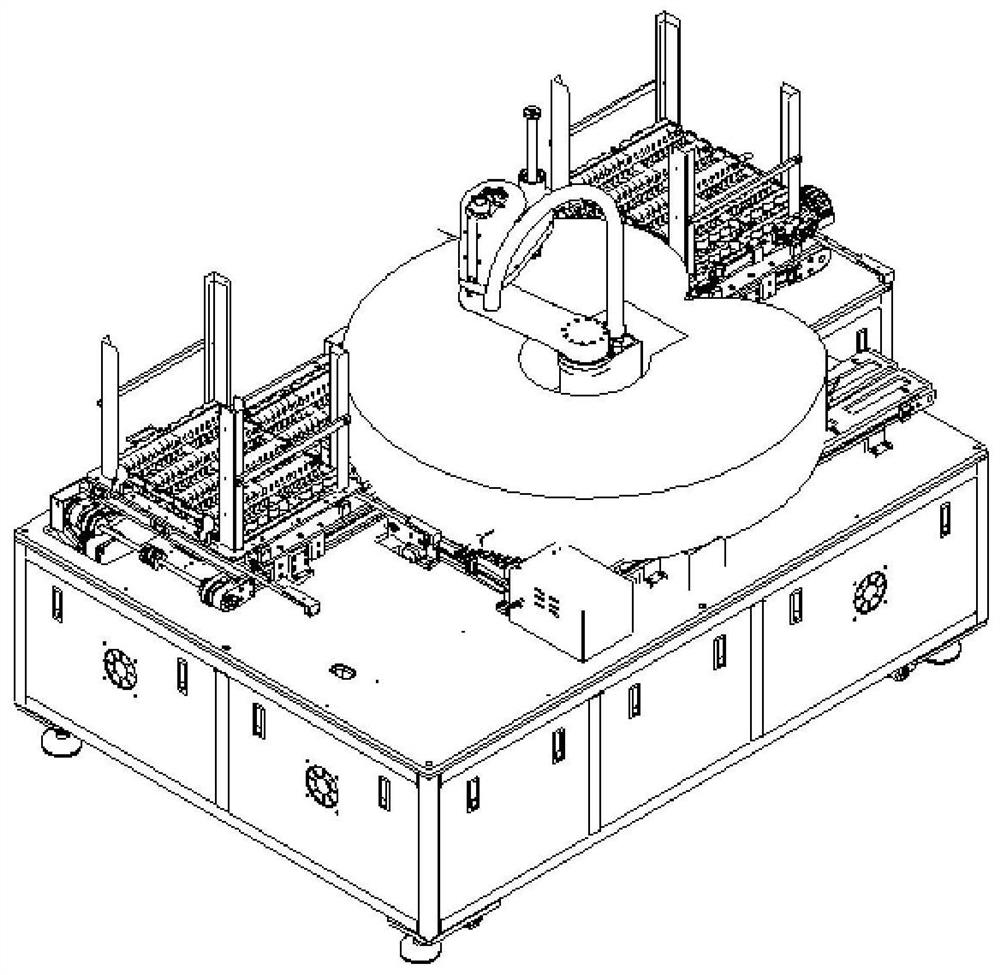

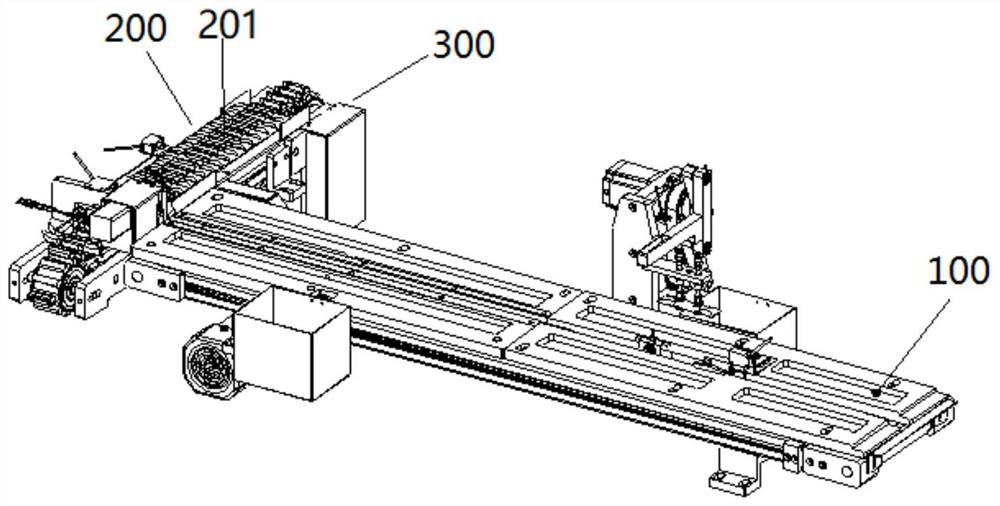

Full-automatic four-edge banding equipment and method for plate

PendingCN109227873AHigh degree of automationSave manpower and material resourcesPolishing machinesBelt grinding machinesMaterial resourcesEngineering

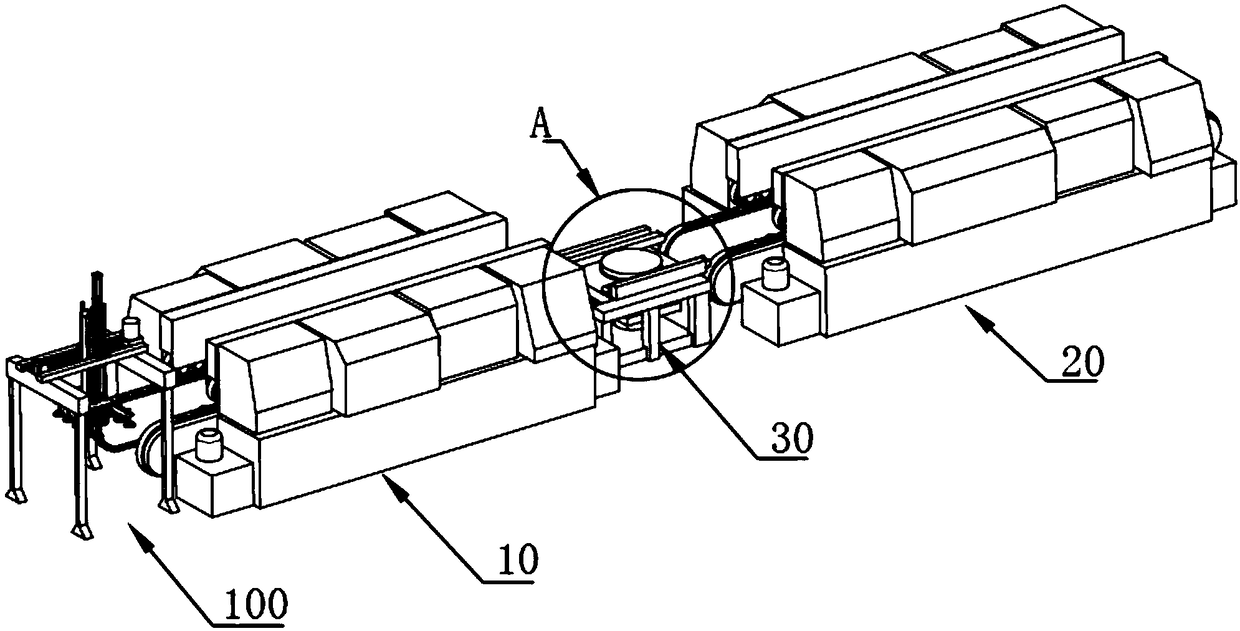

The invention relates to the technical field of plate processing equipment, in particular to full-automatic four-edge banding equipment and method for a plate. The equipment comprises a loading deviceused for taking and loading the plate, a first banding mechanism and a second banding mechanism, wherein a turntable mechanism is connected between the first banding mechanism and the second bandingmechanism, the first banding mechanism comprises a conveying device used for conveying the plate taken by the loading device, a cutting device used for cutting the plate during conveying, a banding device used for banding the cut plate, a trimming device used for trimming the banded plate, a polishing device used for polishing the trimmed plate and a sanding device used for sanding the polished plate. The full-automatic four-edge banding equipment and method for the plate have the advantages that the plate is full-automatically loaded, conveyed, cut, gummed, banded, compressed, cut off, trimmed, polished and sanded, and then repeatedly performs the above process on the plate to achieve four-edge banding, thereby solving the problem that the plate is cut and banded through manpower or half-automatic equipment in the prior art, the degree of automation is high, and the manpower and material resources are saved.

Owner:东莞市春旭机械科技有限公司

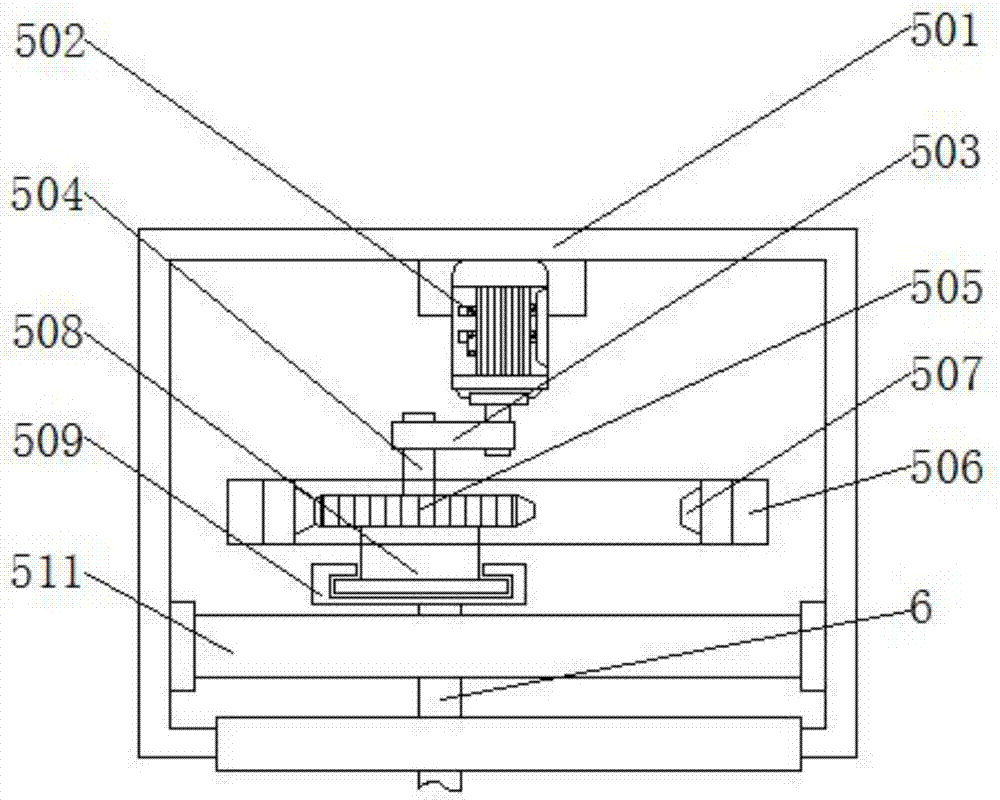

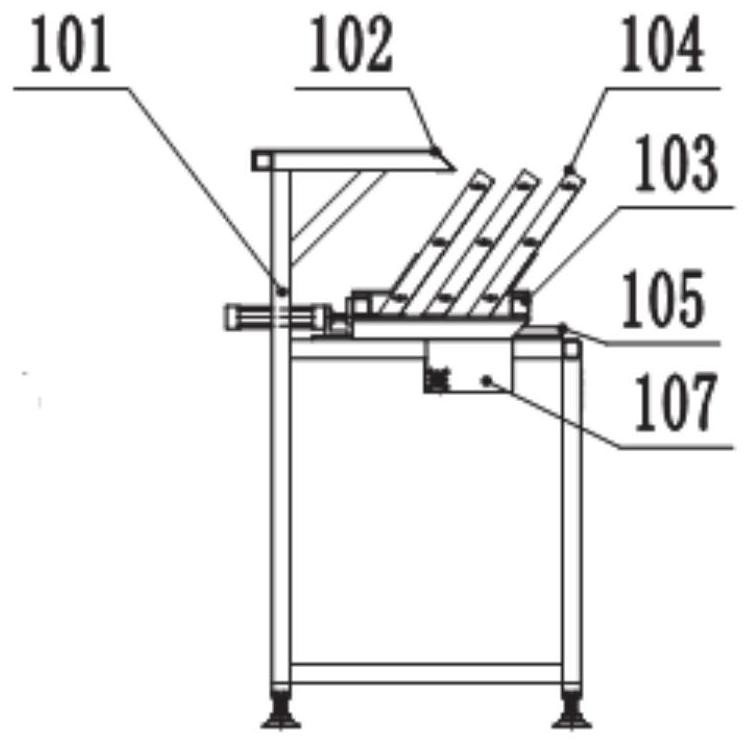

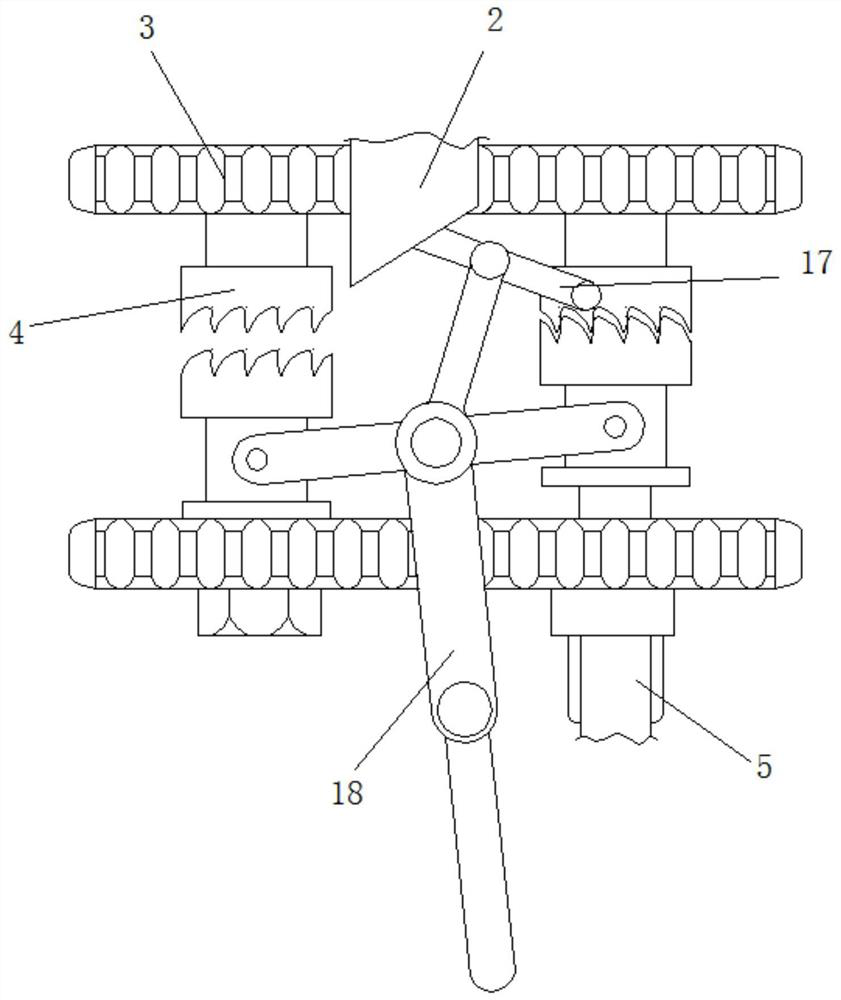

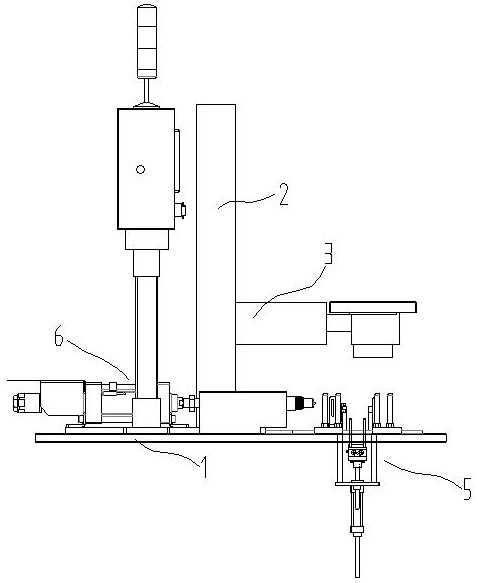

Automatic charging and grinding machine

InactiveCN107413440ASolve the problem of manual feedingReduce labor intensityCocoaGrain treatmentsPiston rodElectrical and Electronics engineering

The invention relates to an automatic feeding grinder, comprising a feeding mechanism and a grinding mechanism; the feeding mechanism includes a feeding frame, a feeding plate and a feeding cylinder, the feeding plate is pivotally connected to the charging frame, and the piston of the charging cylinder The rod is connected with the feeding plate to drive the feeding plate to overturn and feed; the grinding mechanism includes a grinder and a grinding block, and the grinder is provided with a feed port and a discharge port, and the feed port of the grinder is arranged on the Below the feeding plate, the grinding block is arranged in the grinder. The automatic feeding grinder of the present invention is equipped with a feeding mechanism and a grinding mechanism, uses a feeding cylinder to drive the feeding plate to turn over and automatically feeds, and the grinding mechanism grinds the material, which solves the problem that the grinding machine in the prior art needs manual feeding, and improves the Feeding accuracy and production efficiency reduce the labor intensity of workers.

Owner:台山市柔利特研磨科技有限公司

Automatic pupa screening device

PendingCN107185847ASolve the speed problemSolve quality problemsSortingClimate change adaptationEngineeringStructural engineering

The invention relates to the field of machining equipment for by-products in the cocoon silk industry, in particular to an automatic pupa screening device. The automatic pupa screening device comprises a supporting frame, a discharging bin, a vibrator, a first conveying belt assembly, a first high-pressure impact water device, first high-speed shooting equipment, a good pupa collecting box and a bad pupa collecting box; the discharging bin is mounted above the supporting frame; a discharging port is formed in the bottom surface of the discharging bin; the vibrator is mounted on the discharging bin and is connected with the discharging bin; the first conveying belt assembly is arranged below the discharging port and is connected with the supporting frame; the first high-speed shooting equipment is mounted above the first conveying belt assembly; the first high-pressure impact water device is mounted on one side of the first conveying belt assembly; a lens and the spray direction face the conveying surface of the first conveying belt assembly; the good pupa collecting box is mounted at the conveying tail end of the first conveying belt assembly; and the bad pupa collecting box is mounted on one side of the first conveying belt assembly and is located on the opposite side of the first high-pressure impact water device. The automatic pupa screening device is high in pupa screening efficiency.

Owner:广西上林县斯尔顿丝绸有限公司

Turret punch press with protective shell and use method thereof

ActiveCN109570386ASolve the problem that it is very inconvenient to open and closeImprove convenienceMetal-working feeding devicesShaping safety devicesEngineeringTurret

The invention discloses a turret punch press with a protective shell, and relates to the technical field of turret punch press. The turret punch press with the protective shell comprises supporting columns, a main machine box and an outer bottom plate, wherein the top ends of the supporting columns are fixedly connected with the bottom plate; the middle part of the right side of the main machine box is fixedly connected with a turret block; the top of the right side of the main machine box is fixedly connected with an outer frame; the bottom of the right side of the front side of the outer frame is fixedly connected with a rotary box; a protective door is hinged to the front side of the outer frame; a door lock groove is formed in the left side of the protective door; and the right side ofthe inner wall of the door lock groove is rotatably connected with a first door lock runner through a door lock groove shaft. The turret punch press with the protective shell solves the problem thata protective shell structure adopted by the turret punch press is inconvenient to open and close, effectively improves the convenience of opening and closing the protective door structure of the turret punch press, avoids the use difficulty caused by unfavorable opening and closing of the protective door structure, and greatly reduces the operation error rate of operators.

Owner:新昌县联航机械有限公司

Industrial waste incinerating box with high safety performance

InactiveCN107477583AImprove securitySolve the problem of manual feedingIncinerator apparatusEngineeringToxic industrial waste

The invention discloses an industrial waste incinerating box with high safety performance. The industrial waste incinerating box with high safety performance comprises a base; the right side of the top of the base is fixedly connected with an incinerating box; the bottom of an inner cavity of the incinerating box is fixedly connected with an incinerator; the left side of the incinerating box communicates with a feeding box; the left side of the top of the feeding box is fixedly connected with a feeding device; a material pushing rod penetrates through the bottom of the feeding device; and the bottom end of the material pushing rod penetrates through the top of the feeding box and is fixedly connected with a material pushing block. The invention relates to the technical field of industry. The industrial waste incinerating box with high safety performance can feed materials automatically, can perform spraying fire-extinguishing treatment on a connecting position between the incinerating box and the feeding box, solves the problems that fire is caught at a communicating position between the incinerating box and the feeding box caused by feeding excessive materials and the materials are required to be fed manually in the conventional industrial incinerating box, prevents working personnel from being burnt, improves the safety performance of the industrial waste incinerating box, improves the work efficiency of the working personnel, and meets using requirements of a user.

Owner:HEFEI CHAOYING IND DESIGN CO LTD

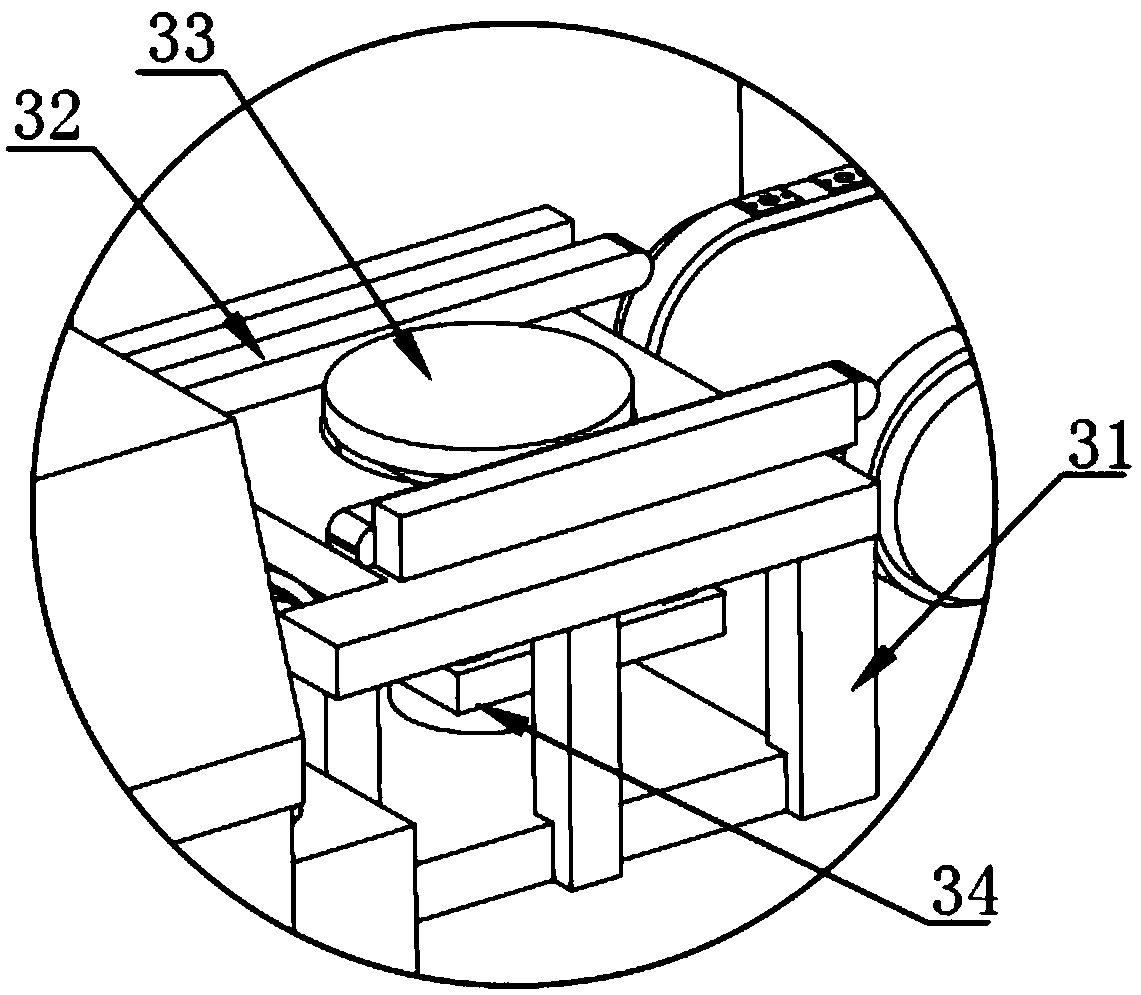

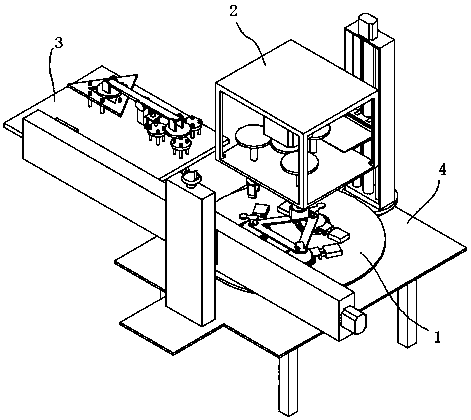

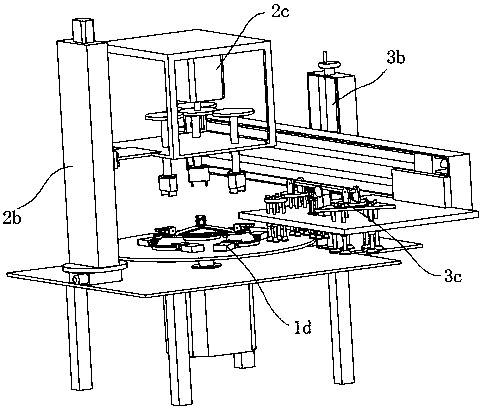

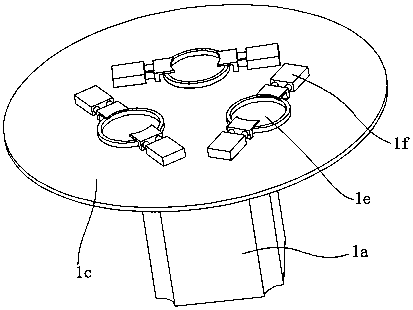

Automatic assembling machine for handheld type three-claw glass sucker

InactiveCN108817900AImprove assembly accuracyFast work efficiencyMetal working apparatusEngineeringHand held

The invention relates to the field of suckers, in particular to an automatic assembling machine for a handheld type three-claw glass sucker. The automatic assembling machine comprises a base, a rotaryworking table, an installing assembly and a feeding assembly. The rotary working table is installed at the middle position of the base. The installing assembly is fixedly installed at the top end ofthe base, and located beside the rotary working table. The feeding assembly is fixedly installed at the top end of the base and located on the other side of the rotary working table. The rotary working table, the installing assembly and the feeding assembly are arranged in a linear state. A first material frame used for feeding a tripod is arranged at one end of the feeding assembly. A second material frame used for sucking skin and carrying out feeding is arranged at the other end of the feeding assembly. A third material frame used for carrying out feeding in a pressing and buckling manner is arranged on one side of the back face of the installing assembly. A fourth material frame used for feeding a connecting rod is arranged on the other side of the back face of the installing assembly.The automatic assembling machine solves the problems that the salary of staff is high, the assembling precision is insufficient, and the working efficiency is poor.

Owner:李义飞

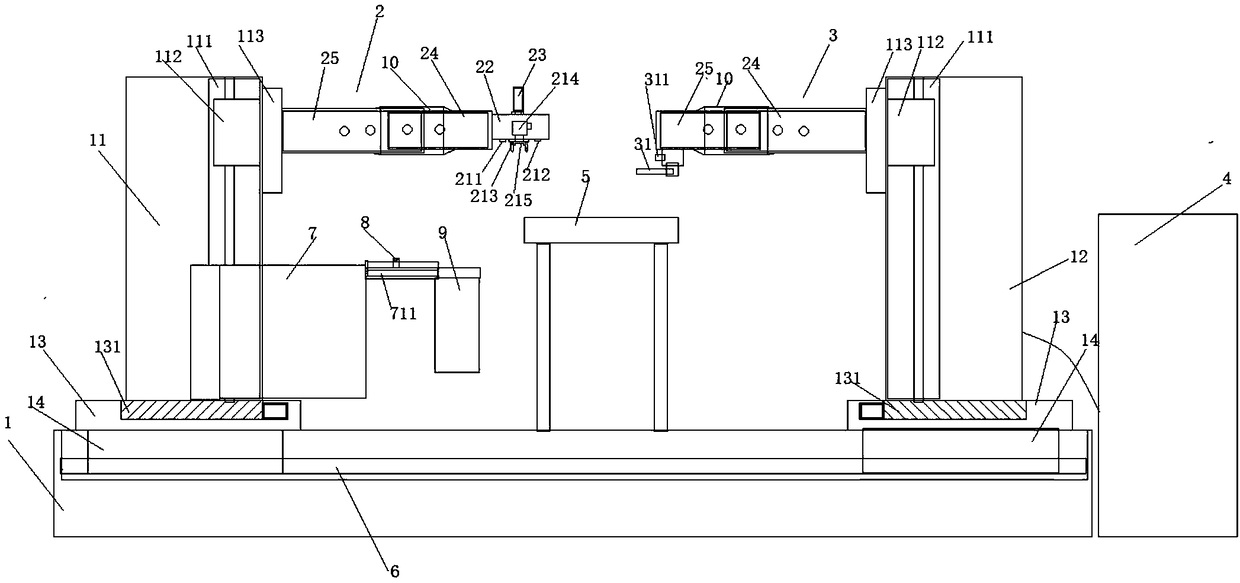

High-efficiency intelligent bottle cap mounting mechanical arm and working method thereof

PendingCN109110704AImprove stabilityImprove installation quality and installation efficiencyCapsCapping machinery safety/controlManipulatorEngineering

The invention discloses a high-efficiency intelligent bottle cap mounting mechanical arm. The high-efficiency intelligent bottle cap mounting mechanical arm comprises a base, a first mechanical arm, asecond mechanical arm and a control device; a first vertical column and a second vertical column are arranged on the base, a working table is arranged between the first stand column and the second stand column, and the first mechanical arm and the second mechanical arm are arranged on the first vertical column and the second vertical column respectively; a track is arranged on the base, the firstvertical column and the second vertical column are oppositely arranged at the two ends of the track, fixing bases are arranged below the first vertical column and the second vertical column, slidingblocks are arranged below the fixing bases, and the sliding blocks are arranged in the rail; an upper cover mechanism is arranged at the end of the first mechanical arm, the mechanical arm is arrangedon the second mechanical arm, a bottle cap position detection mechanism and a bottle mouth position detection mechanism are arranged on the upper cover mechanism, and a position detection mechanism is arranged on the mechanical arm; the first mechanical arm and the second mechanical arm are oppositely arranged on the two sides of the working table, and the first mechanical arm is used for grabbing and installing the bottle cap, and the second mechanical arm is used for fixing the bottle body. According to the high-efficiency intelligent bottle cap mounting mechanical arm, the installation stability of the bottle cap is improved, and the installation efficiency is improved.

Owner:薛敏强

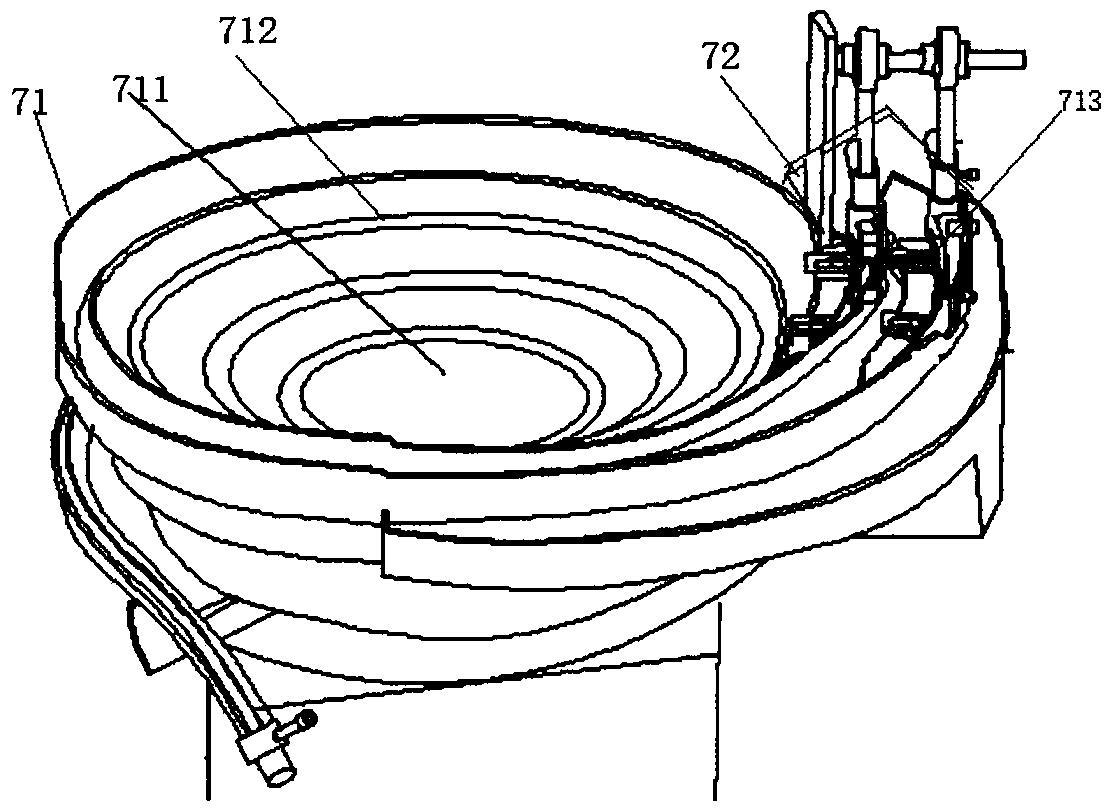

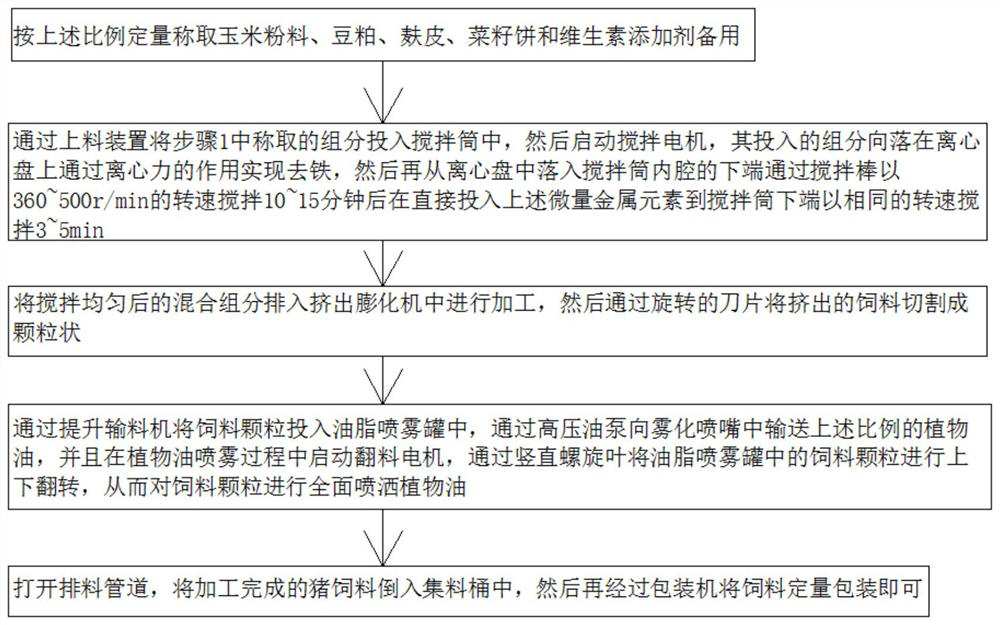

Pig feed formula and processing device thereof

ActiveCN112715752AIncrease profitRich in nutrientsFeeding-stuffFood processingBiotechnologyVegetable oil

The invention relates to the field of pig feed formulas, and particularly discloses a pig feed formula which comprises the following components in parts by weight: 40-55 parts of corn flour, 25-30 parts of soybean meal, 20-30 parts of bran, 10-12 parts of rape seed cakes, 6-8 parts of vegetable oil, 3-5 parts of vitamin additives and 1-2 parts of trace metal elements.

Owner:KUNMING HUAGANG FEED

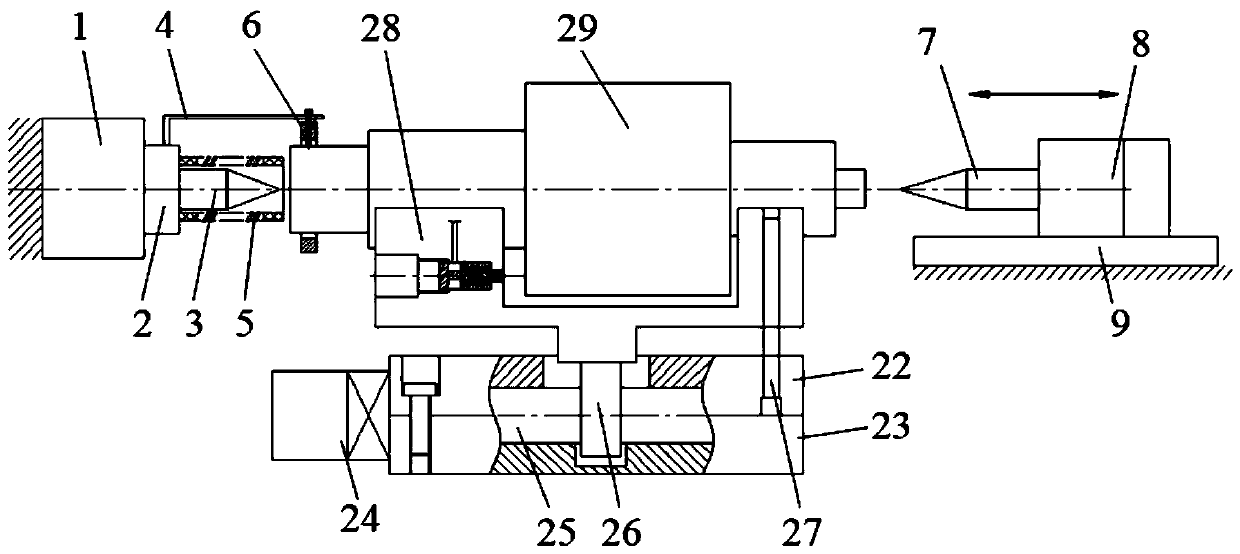

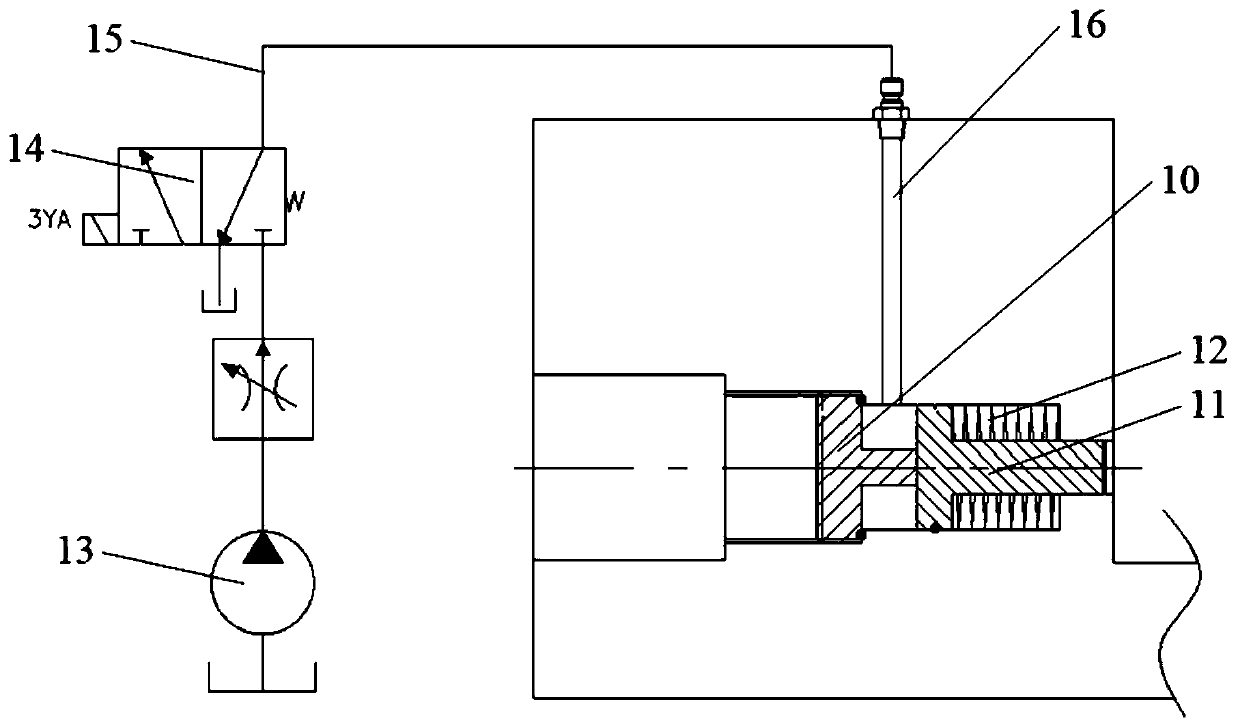

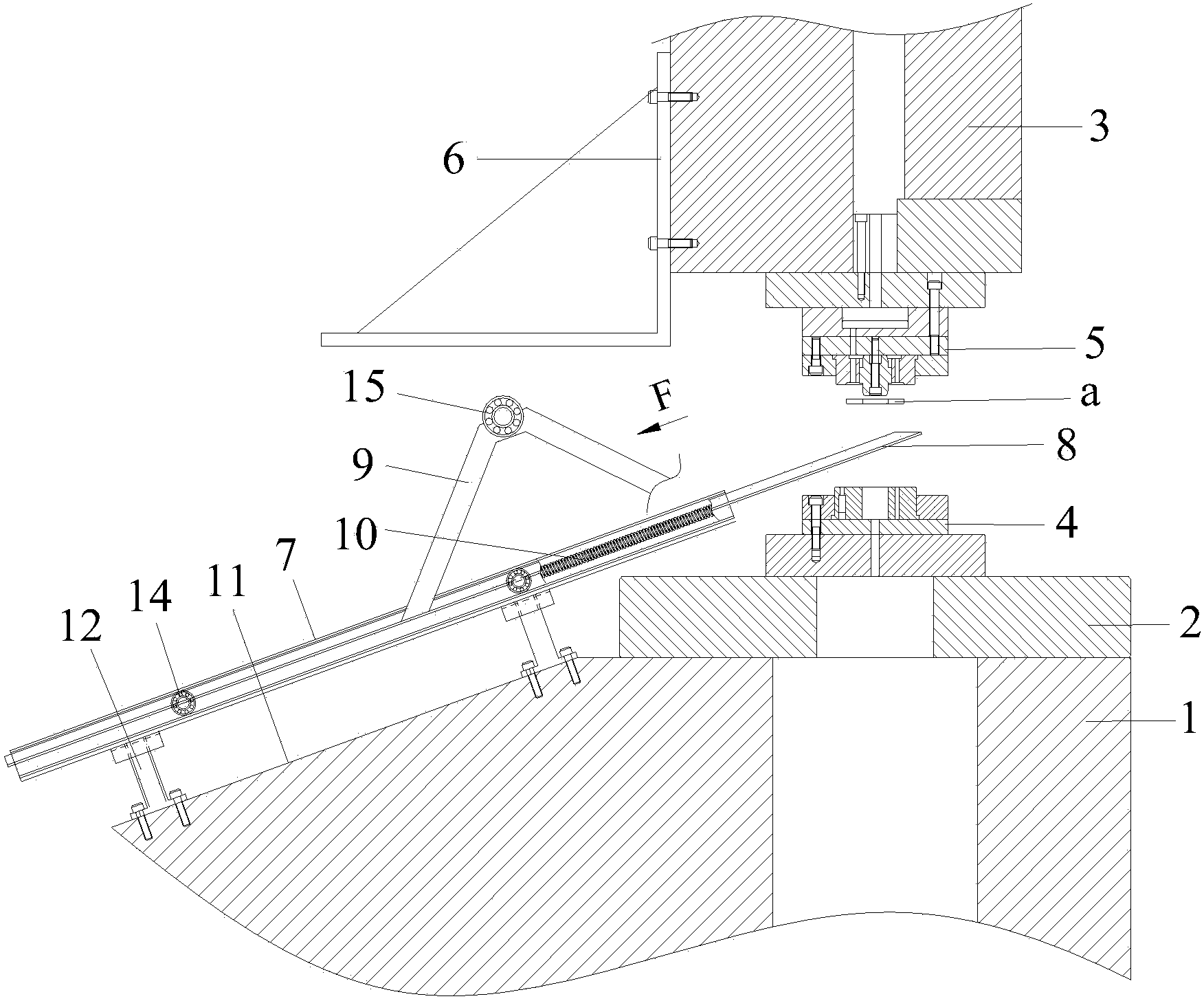

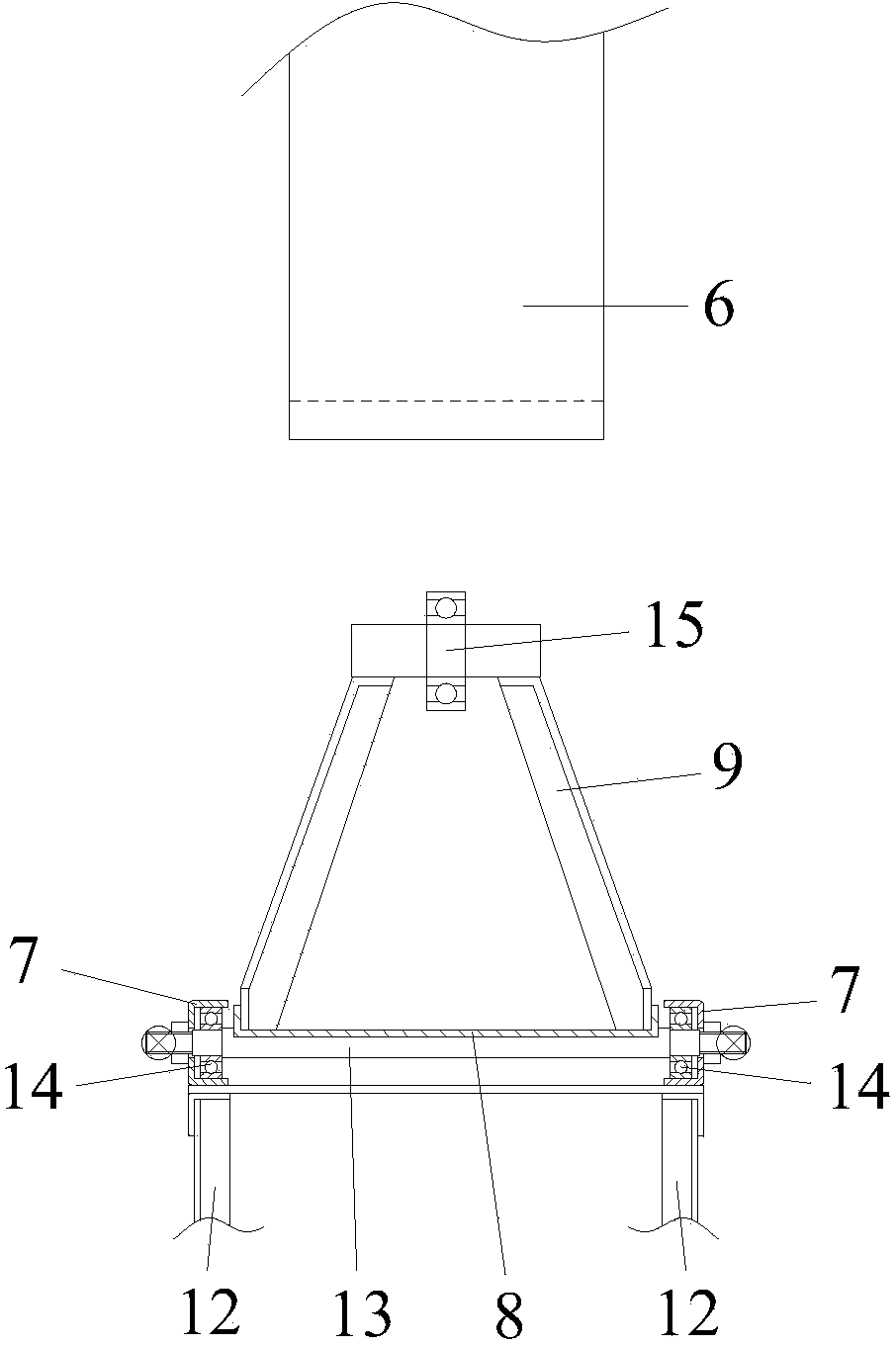

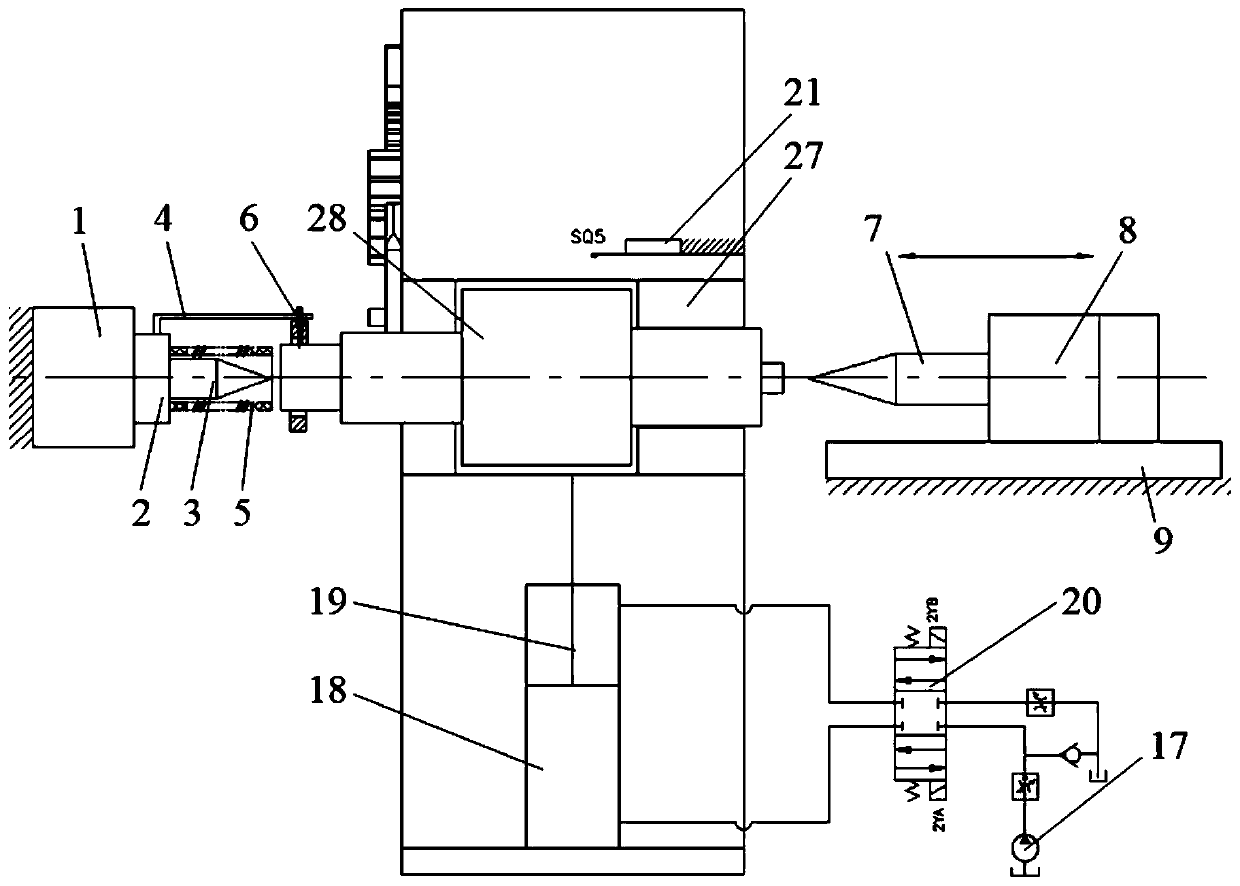

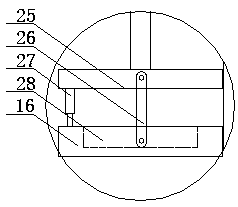

Feeding and positioning device of grinding machine

PendingCN110193758ASolve the problem of manual feedingReduce the labor intensity of manual clampingRevolution surface grinding machinesGrinding drivesTailstockClosed cavity

The invention discloses a feeding and positioning device of a grinding machine. A rotating part is arranged on a rack of the grinding machine, and the second end of the rotating part is used for positioning a workpiece. A tailstock positioning part comprises a tailstock center and a tailstock driving part, and the tailstock driving part is arranged on the rack. The tailstock center is arranged onthe tailstock driving part. A feeding part comprises a bearing part, a lifting part, a positioning assembly and a moving part. The moving part is arranged on the rack. The lifting part is arranged onthe moving part. The bearing part is arranged on an output shaft of the lifting part, and the bearing part is further provided with a positioning surface for positioning the workpiece. The positioningassembly is arranged in the containing cavity in the bearing part. The first end of a fixing block in the positioning assembly is connected with the first end of the containing cavity. The first endof a push-out block is connected with the second end of the fixing block, the push-out block and the fixing block are matched with the inner wall surface of the containing cavity to form a closed cavity, and the second end of the push-out block is connected with the workpiece. A gas conveying part communicates with the closed cavity. The first end of a reset spring is connected with the push-out block, and the second end of the reset spring is connected with the containing cavity.

Owner:SUZHOU INST OF TRADE & COMMERCE

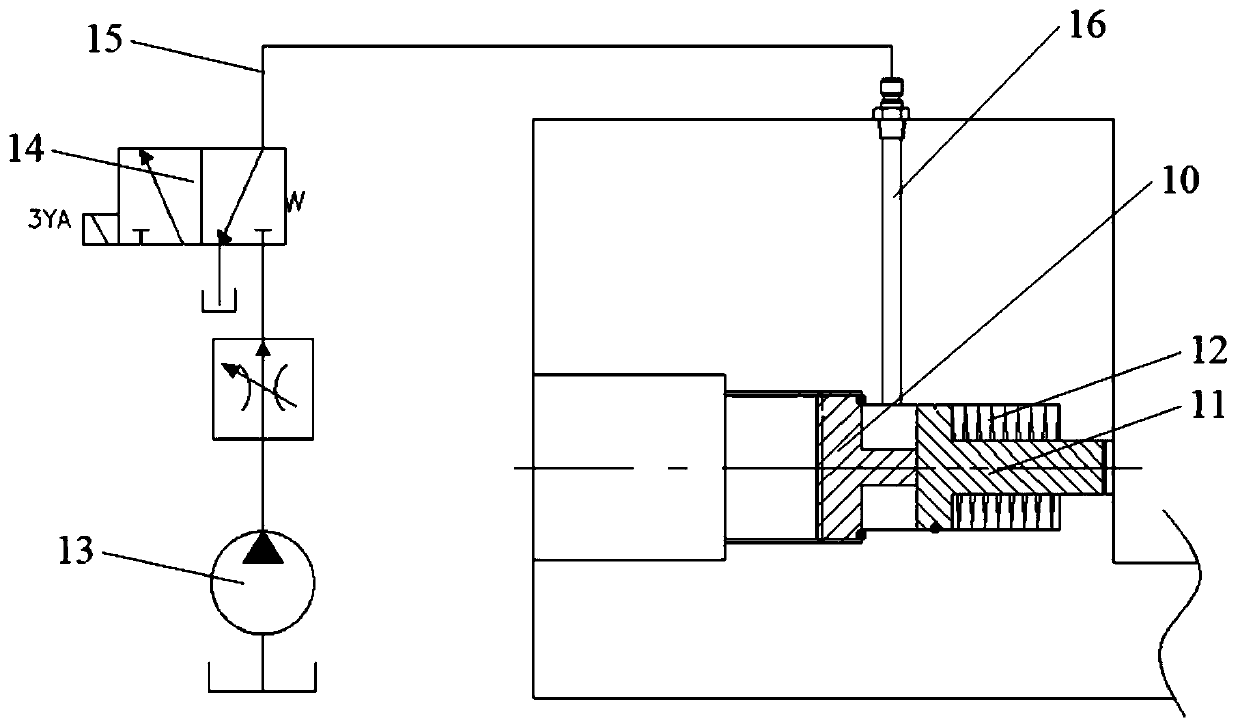

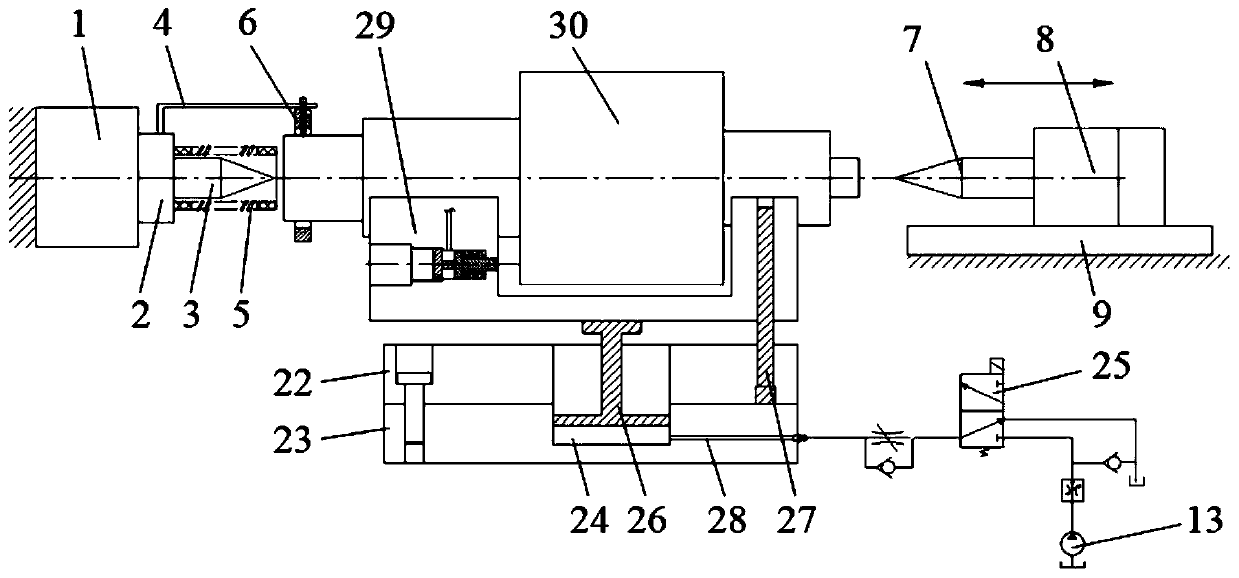

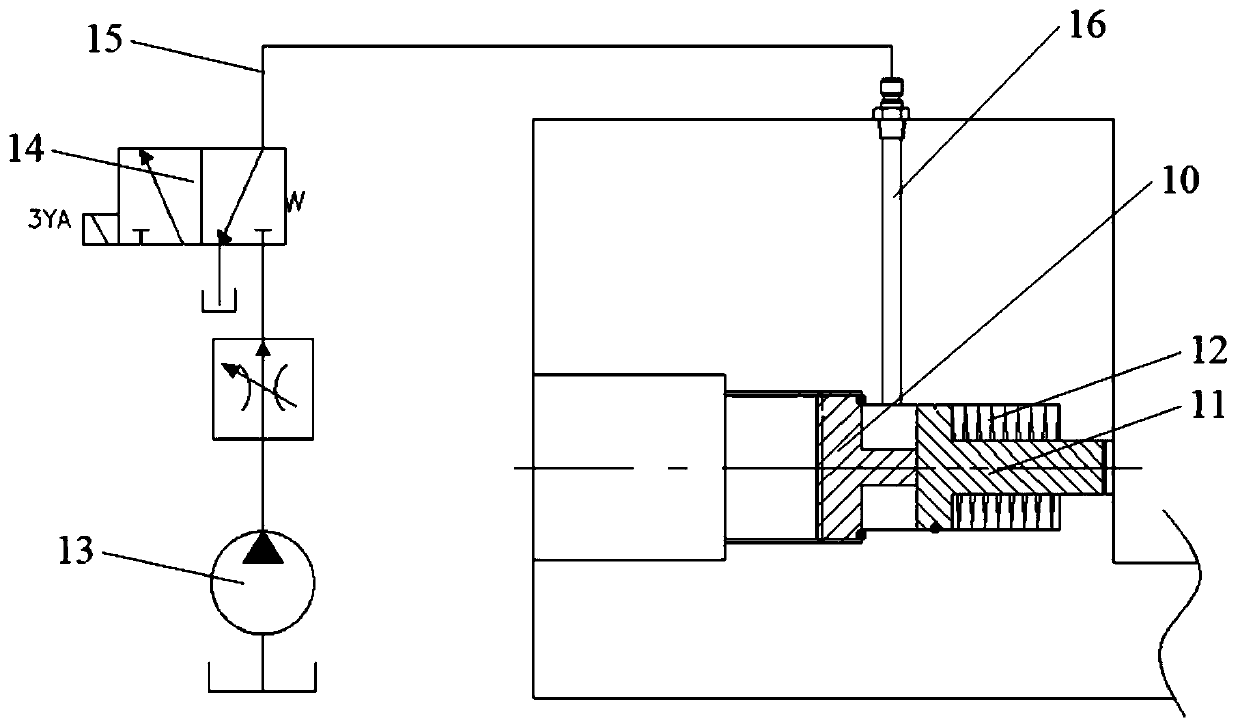

Hydraulic type grinding machine feeding positioning device

ActiveCN110253351ASolve the problem of manual feedingReduce the labor intensity of manual clampingRevolution surface grinding machinesGrinding work supportsMechanical engineeringEngineering

The invention discloses a hydraulic type grinding machine feeding positioning device. The hydraulic type grinding machine feeding positioning device comprises a rotary portion, a tail seat positioning portion, a feeding portion, a gas transportation portion and a reset spring, wherein the rotary portion is arranged on a machine frame of a grinding machine, a second end of the rotary portion is used for positioning a workpiece, the tail seat positioning portion comprises a tail seat tip and a tail seat drive portion, the tail seat drive portion is arranged on the machine frame, the tail seat tip is arranged on the tail seat drive portion, the feeding portion comprises a bearing portion, a lifting portion, a positioning assembly and a moving portion, the moving portion is arranged on the machine frame, the lifting portion is arranged on the moving portion, the bearing portion is arranged on an output shaft of the lifting portion, the bearing portion is provided with a positioning face for positioning the workpiece, the positioning assembly is arranged in a containing cavity in the bearing portion, a first end of a fixed block in the positioning assembly is connected with a first end of the containing cavity, a first end of a push-out block of the positioning assembly is connected with a second end of the fixed block, the push-out block, the fixed block and the inner wall face of the containing cavity cooperate to form a sealed cavity body, a second end of the push-out block is connected with the workpiece, the gas transportation portion communicates with the sealed cavity body, a first end of the reset spring is connected with the push-out block, and a second end of the reset spring is connected with the containing cavity.

Owner:SUZHOU INST OF TRADE & COMMERCE

Efficient and intelligent bottle cap mounting robot arm

PendingCN108821207ASolve the costSolve the problem of land occupationCapsCapping machinery safety/controlSimulationBottle cap

The invention discloses an efficient and intelligent bottle cap mounting robot arm. The efficient and intelligent bottle cap mounting robot arm comprises a base, a first robot arm, a second robot armand a control device. The base is provided with a stand column, and the first robot arm and the second robot arm are both mounted on the stand column. A transmission mechanism is disposed between thefirst robot arm and the second robot arm, and the first robot arm and the second robot arm are matched with each other. A cap feeding mechanism for grasping bottle caps is arranged on the end portionof the first robot arm, and the second robot arm is provided with a tightening mechanism for tightening the bottle caps. The cap feeding mechanism is provided with a bottle cap position detecting mechanism and a bottle mouth position detecting mechanism, and the tightening mechanism is provided with a position detecting mechanism for detecting the position of a bottle body. According to the efficient and intelligent bottle cap mounting robot arm, the structure is simple and optimized, and the transmission mechanism is arranged between the first robot arm and the second robot arm, so that the first robot arm and the second robot arm realize the pipelined operation, two stations are subjected to cap feeding and screwing simultaneously and each of the two stations performs own duties, and thus the work efficiency is effectively improved.

Owner:薛敏强

Plate automatic surface cutting, edge sealing, edge cutting and sanding system and method thereof

PendingCN109015941AFeel goodImprove protectionEdge grinding machinesProfiling/shaping machinesMotor driveSemi automatic

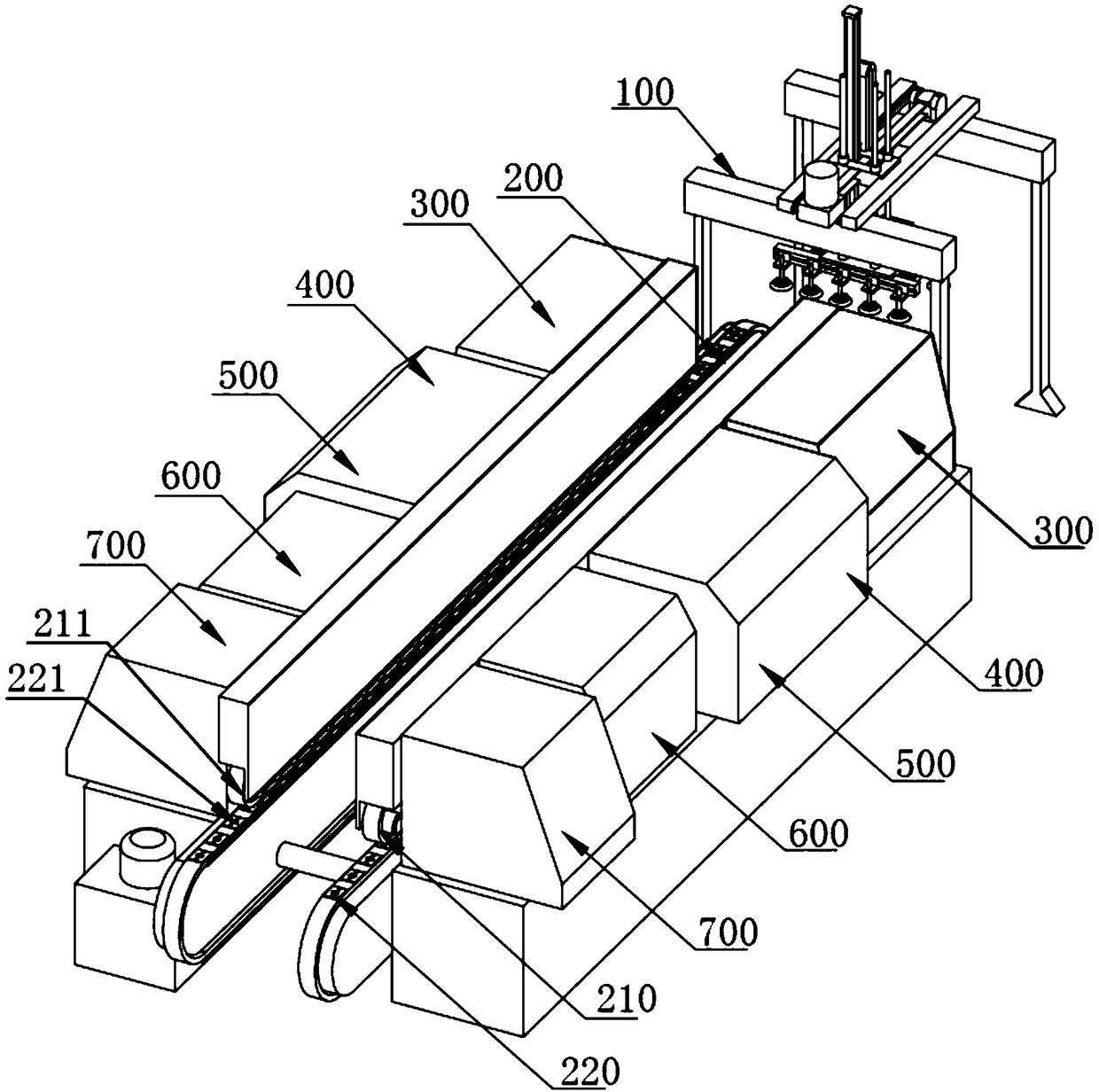

The invention relates to the technical field of plate processing equipment, in particular to a plate automatic surface cutting, edge sealing, edge cutting and sanding system and a method thereof. Theplate automatic surface cutting, edge sealing, edge cutting and sanding system comprises a material loading device, a conveying device, a surface cutting device, an edge sealing device, an edge trimming device and a sanding device; the surface cutting device, the edge sealing device, the edge trimming device and the sanding device are arranged on the conveying device in sequence; the material loading device is positioned on one side of the conveying device; the sanding device comprises an external cover and a sanding motor which is mounted on the external cover; the sanding motor drives a sandbelt; and guide rolls used for guiding the sand belt, a sanding driving component used for driving the sand belt to sand plates and a press plate which is in driving connection with the sanding driving component to press the sand belt to the plate are mounted on the external cover. According to the plate automatic surface cutting, edge sealing, edge cutting and sanding system, through full-automatic loading, conveying, surface cutting, glue coating, edge sealing, pressing, cutting-off, edge trimming and sanding works of the plate, problems caused by using existing manual or semi-automatic equipment to cut the surface of the plate and seal the edge of the plate are solved, the automation degree is high, and human and material resources are saved.

Owner:东莞市春旭机械科技有限公司

Mould processing collecting technology

InactiveCN103639319AReduce labor intensityTo achieve the purpose of automatic feedingMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention discloses a mould processing collecting technology. According to the technology, an upper mould, a lower mould and a mould of an automatic collector are included. The automatic collector comprises an upper pressing block and two sliding rails. A collecting plate is mounted between the two sliding rails, one end of the collecting plate stretches into the middle of the upper mould and the lower mould, and a support is fixed on the collecting plate. The upper pressing block and the upper mould are moved downwards, so that the upper pressing block presses and pushes the support and drives the collecting plate to be separated from the middle of the upper mould and the lower mould, and the upper mould and the lower mould are closed to press a product. The upper pressing block and the upper mould are moved upwards, so that the pressed product moves upwards along with the upper mould, the upper pressing block is separated and presses a sliding bearing, and the collecting plate enters the middle of the upper mould and the lower mould and is disposed below the pressed product. The pressed product is separated from the upper mould to fall into the collecting plate, so that the product is leaked in a product frame along the collecting plate under the machine tool vibration. By means of the mould processing collecting technology, the worker labor intensity is reduced, and the production efficiency is improved.

Owner:珠海科林模具有限公司

Automatic gluing device

InactiveCN112354799AWon't pile upSolve the problem of manual feedingLiquid surface applicatorsSpraying apparatusEngineeringWorkbench

The invention discloses an automatic gluing device, and belongs to the technical field of gluing devices. The automatic gluing device comprises a workbench, a feeding assembly, a glue spraying assembly, a moving assembly, a lifting assembly and scraping assemblies, wherein supporting legs are arranged on the lower side of the workbench, and the workbench is arranged on the ground through the supporting legs; a supporting frame is also arranged on the workbench; the feeding assembly is arranged on one side of the workbench; the glue spraying assembly is arranged on one side of the supporting frame; a long groove is formed in the supporting frame, and the moving assembly is arranged in the long groove of the supporting frame; the working end of the glue spraying assembly is arranged at the working end of the moving assembly; one end of the lifting assembly is arranged on the ground, and the other end of the lifting assembly penetrates through the workbench and extends to a position abovethe workbench; and the two scraping assemblies are arranged on the two sides of the workbench. Through the arrangement of the moving assembly, the dispensing rate of the device is greatly increased.

Owner:惠州市迪凡家具有限公司

Full-automatic edge banding equipment and method for section of sheet material

PendingCN109227874AHigh degree of automationSave manpower and material resourcesPolishing machinesBelt grinding machinesEngineeringMaterial resources

The invention relates to the technical field of sheet material processing equipment, in particular to full-automatic edge banding equipment and method for the section of a sheet material. The equipment comprises a loading device, a conveying device, a cutting device, an edge banding device, a trimming device, a polishing device and a sanding device, wherein the loading device is used for taking and loading the sheet material, the conveying device is used for conveying the sheet material taken by the loading device, the cutting device is used for cutting the sheet material during conveying, theedge banding device is used for banding the edge of the cut sheet material, the trimming device is used for trimming the edge-banded sheet material, and the polishing device is used for polishing thetrimmed sheet material, the sanding device is used for sanding the polished sheet material; the cutting device, the edge banding device, the trimming device, the polishing device and the sanding device are arranged on the conveying device in sequence, and the loading device is located at one side of the conveying device. The full-automatic edge banding equipment and method for the section of thesheet material have the advantages that the sheet material is full-automatically loaded, conveyed, cut, gummed, banded, compressed, cut off, trimmed, polished and sanded, thereby solving the problem that the sheet material is cut and banded through manpower or half-automatic equipment in the prior art, the degree of automation is high, and the manpower and material resources are saved.

Owner:东莞市春旭机械科技有限公司

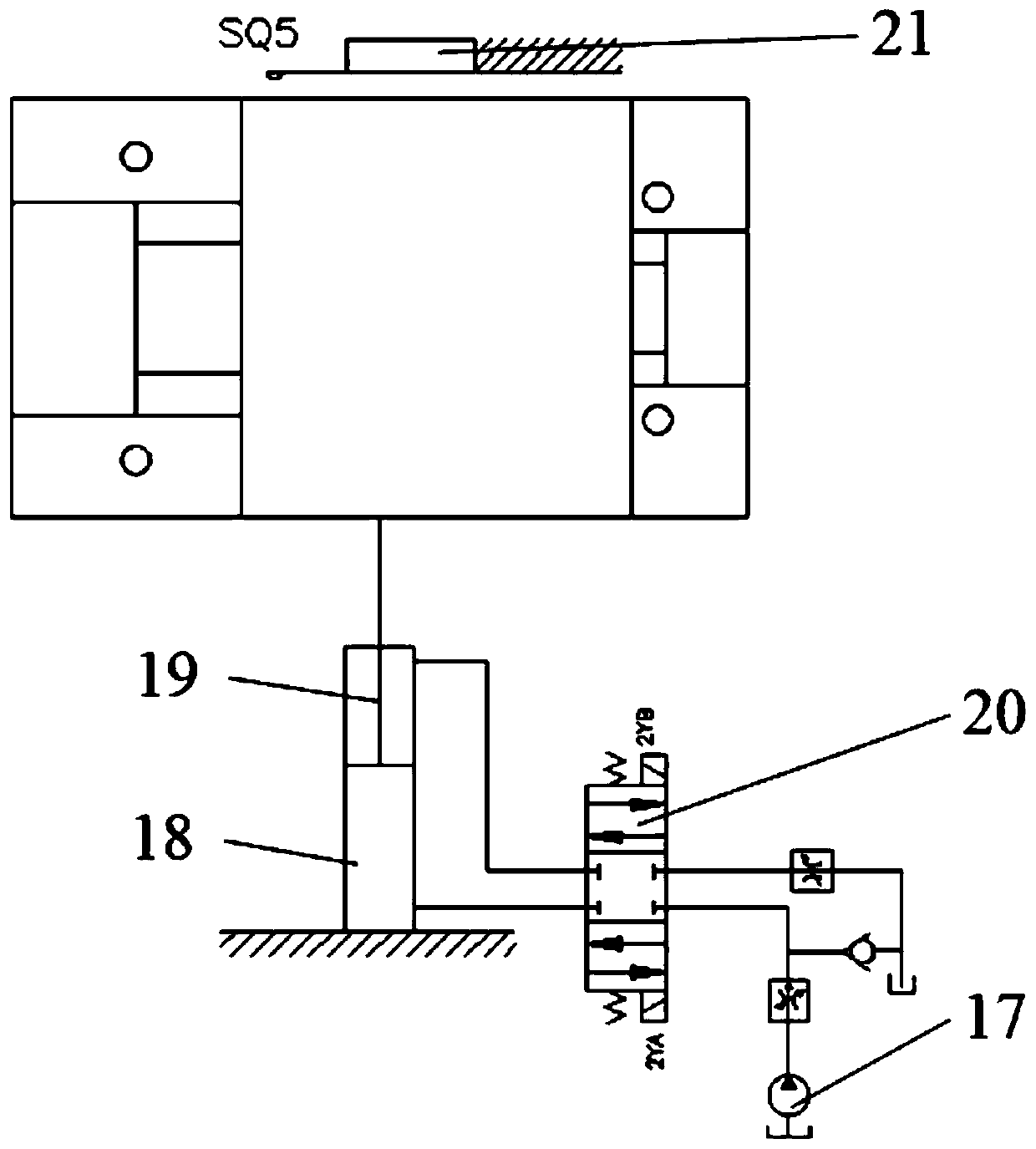

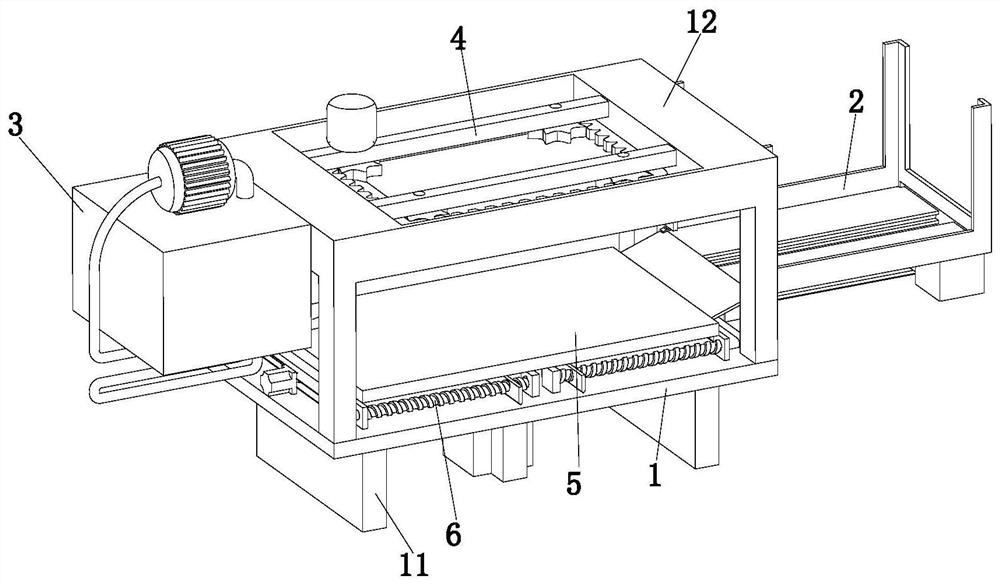

Hydraulic type inclined grinding machine feeding positioning device

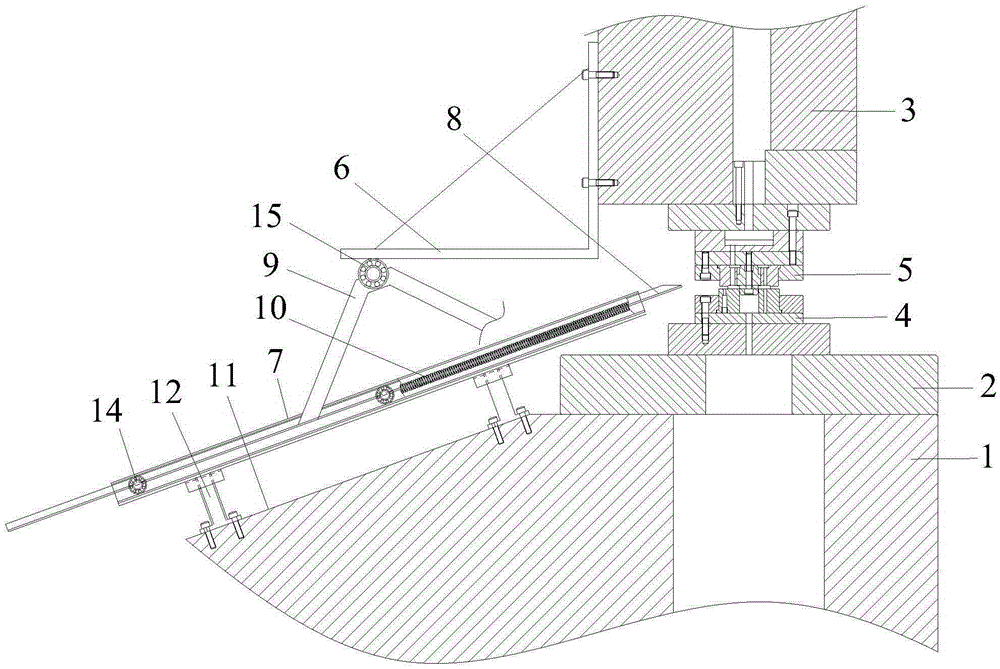

PendingCN110181399ASolve the problem of manual feedingReduce labor intensityGrinding work supportsEngineeringTailstock

The invention discloses a hydraulic type inclined grinding machine feeding positioning device. A rotary part is arranged on a rack of a grinding machine, the rotary part is used for positioning a workpiece, a tail base positioning part comprises a tail base tip, and a tail base driving part, the tail base driving part is arranged on the rack, the tail base tip is arranged on the tail base drivingpart, a feeding part comprises a bearing part, an inclined lifting part, a positioning assembly and a moving part, the moving part is arranged on the rack, the inclined lifting part is arranged on themoving part, the bearing part is arranged on an output shaft of the inclined lifting part, and a positioning face for positioning the workpiece is arranged on the bearing part. The positioning assembly is arranged in a containing cavity in the bearing part. The first end of a fixed block in the positioning assembly is connected with the first end of the containing cavity, the first end of a pushing block is connected with the second end of the fixed block, the pushing block and the fixed block are matched with the inner wall face of the containing cavity to form a closed cavity, and the second end of the pushing block is connected with the workpiece; a gas conveying part communicates with the closed cavity; and the two ends of a reset spring are connected with the pushing block and the containing cavity.

Owner:SUZHOU INST OF TRADE & COMMERCE

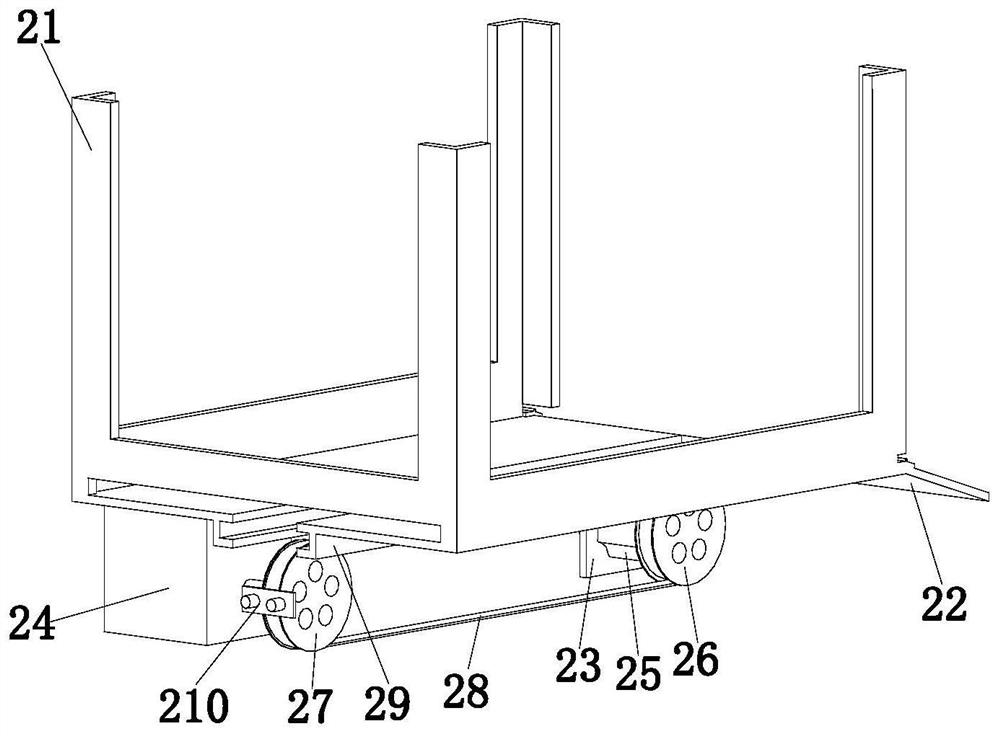

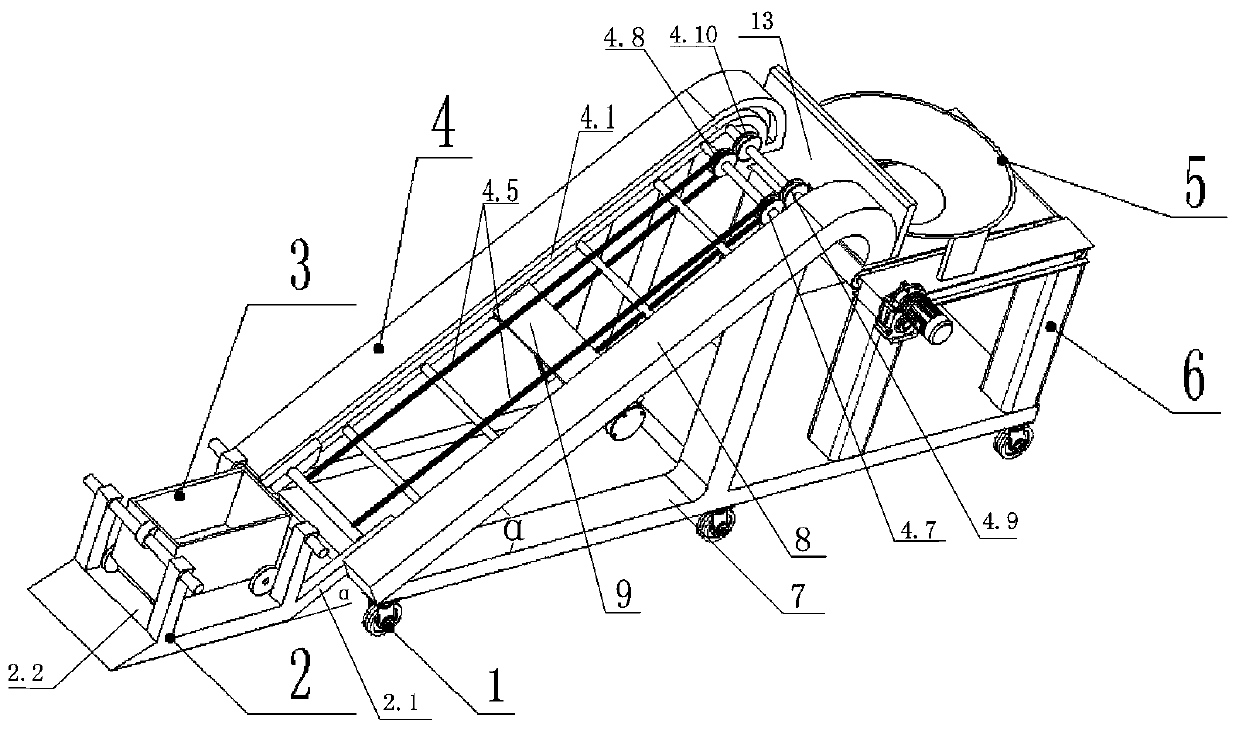

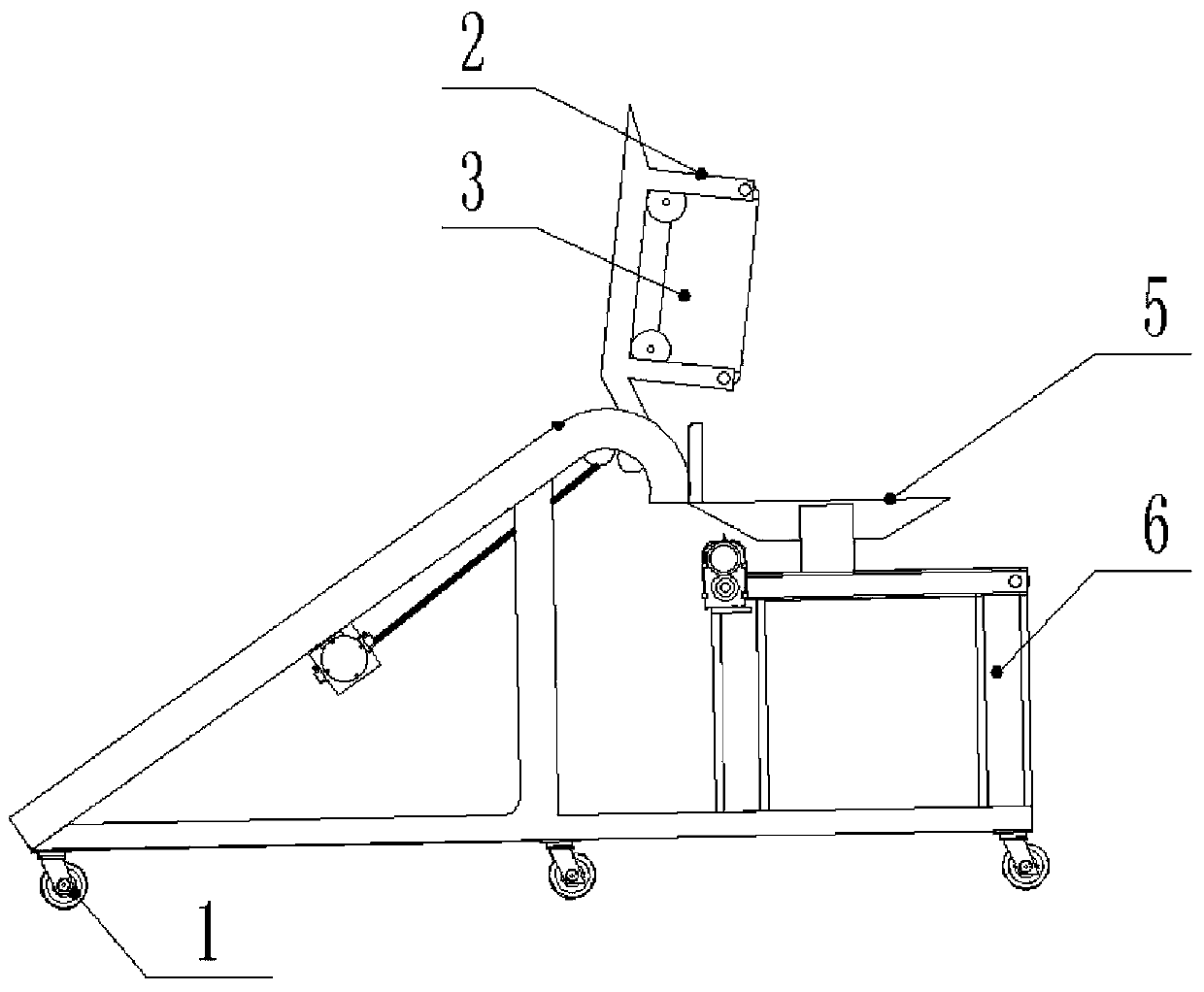

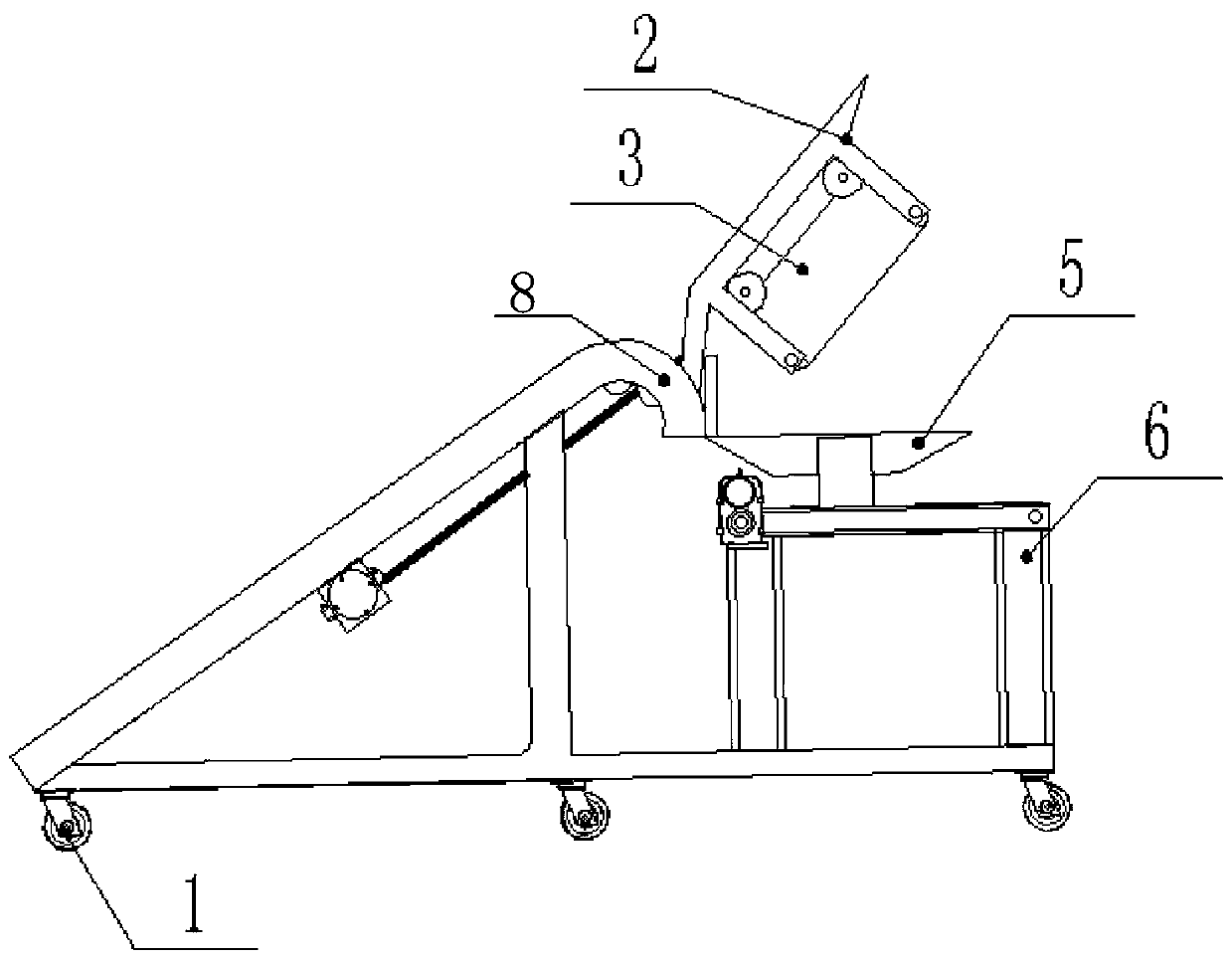

Tramcar automatic feeding device used for wet pulp shooting machine

InactiveCN109823789ASolve the problem of manual feedingProtect your healthUnderground chambersSupporting framesEngineeringBelt conveyor

The invention discloses a tramcar automatic feeding device used for a wet pulp shooting machine. A belt type conveying rack is mounted on the front portion of a rack. A funnel opening is located abovea belt of a belt conveyor. A left guide rail and a right guide rail are erected on the belt type conveying rack and located behind a funnel. Roller wheels on the two sides of a conveying frame are arranged in corresponding guide roller grooves of the left guide rail and the right guide rail correspondingly and do back and forth movement along the left guide rail and the right guide rail under traction of a traction mechanism to convey and feed a tramcar. Materials are dumped through automatic turnover. The device is simple in structure and stable and reliable in operation. Forward and reverserotation of a roller is controlled through a motor to achieve feed; operation is simple; the problems about manual feed of the wet pulp shooting machine are solved; the automatic feed efficiency is high; little power is needed; the work efficiency is greatly improved; the labor intensity is reduced; the body health of workers is guaranteed; and therefore manual hidden danger is eliminated.

Owner:CHINA UNIV OF MINING & TECH

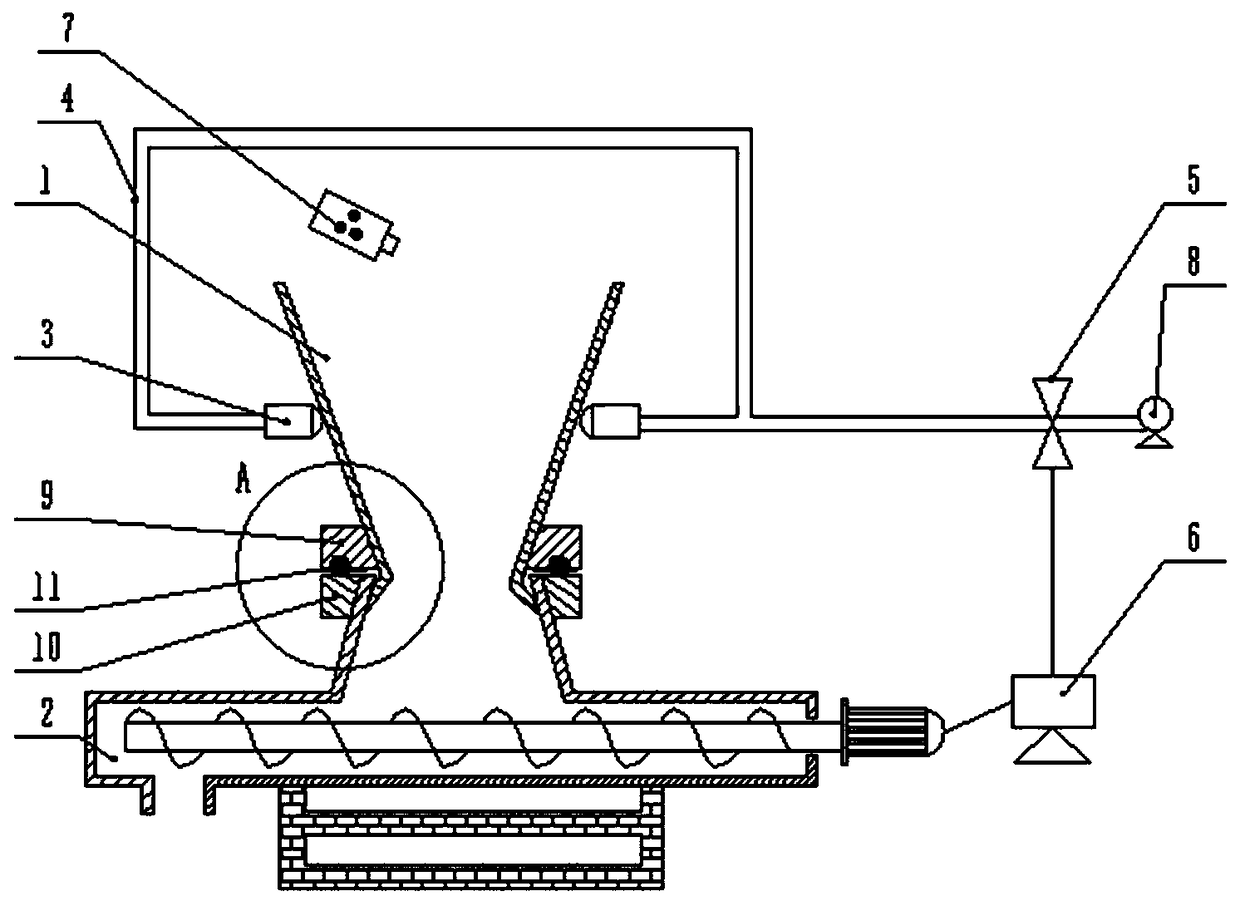

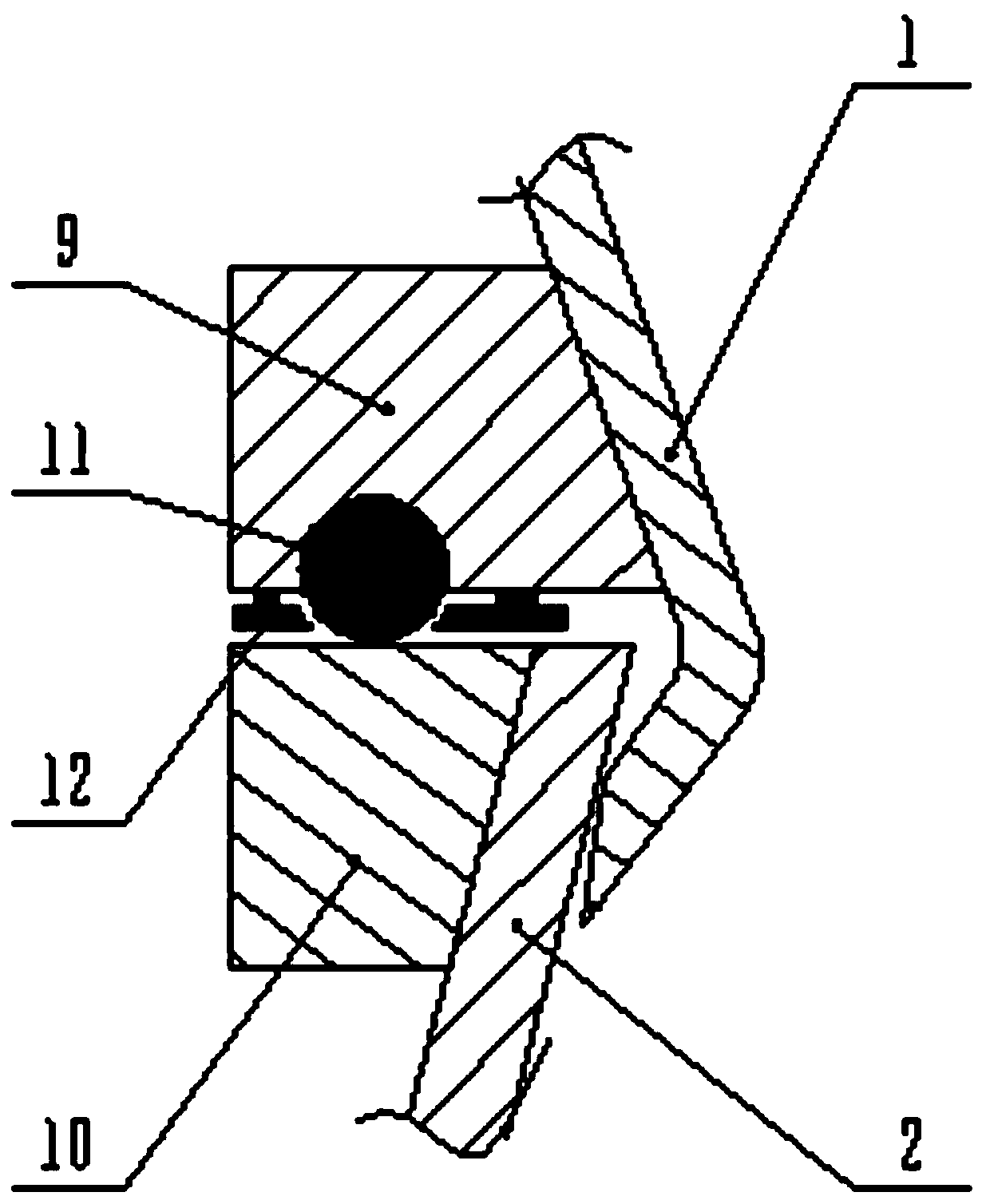

Automatic feeding device for synthetic explosive raw material

PendingCN109110314AFully automatedAvoid damageLarge containersLoading/unloadingMan machinePersonal computer

The invention relates to an automatic feeding device for a synthetic explosive raw material, and belongs to the technical field of automatic feeding equipment. The device capable of achieving man-machine isolation and automatic synthetic explosive raw material feeding is provided. According to the technical scheme, the automatic feeding device for the synthetic explosive raw material comprises a feeding hopper, a screw feeder, oscillators, an industrial personal computer, feeding hopper supporting seats, saddles and balls; the screw feeder is arranged below the feeding hopper, and an outlet ofthe feeding hopper is movable arranged at an inlet of the screw feeder; the lower portion of one end of the screw feeder is provided with a material outlet, and the other end of the screw feeder is provided with a motor; the feeding hopper supporting seats are welded to the outer wall of the lower portion of the feeding hopper, the saddles are welded to the outer wall of the upper portion of thescrew feeder, and the feeding hopper supporting seats are matched with the saddles. The automatic feeding device completes automatic feeding and achieves the automation and man-machine isolation purposes in the feeding process.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

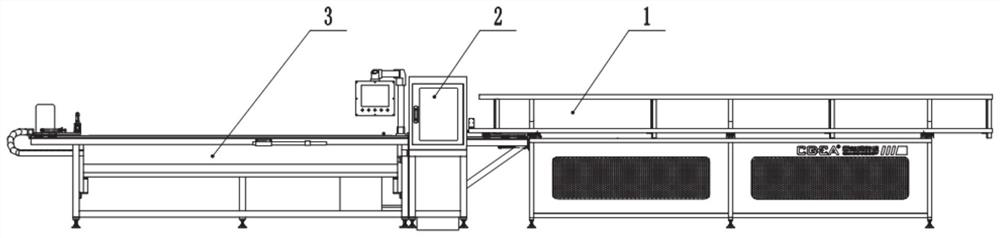

Full-automatic numerical control batten cutting saw, production line and method

PendingCN111745213ASolve the problem of manual feedingSolve the problem of manual loadingMetal sawing devicesMetal sawing accessoriesNumerical controlProduction line

The invention provides a full-automatic numerical control batten cutting saw, a production line and a method. The full-automatic numerical control batten cutting saw comprises a main machine frame, afeeding mechanism, a positioning mechanism and a feed mechanism, wherein the feeding mechanism, the positioning mechanism and the feed mechanism are sequentially arranged at the top of the main machine frame from left to right; and the feed mechanism comprises a transmission mechanism and a feeding plate, a limiting piece is installed at one end of the feeding plate, the other end of the feeding plate is connected with the transmission mechanism, and the feeding plate is in sliding connection with the main machine frame. The problems of manual feeding, how to achieve excess material treatmentof aluminum alloy batten profiles, automatic sorting of finished products after aluminum alloy batten cutting and wireless remote measurement are solved, the labor intensity is reduced, and the working efficiency is improved.

Owner:JINAN CGMA CNC MACHINERY CO LTD

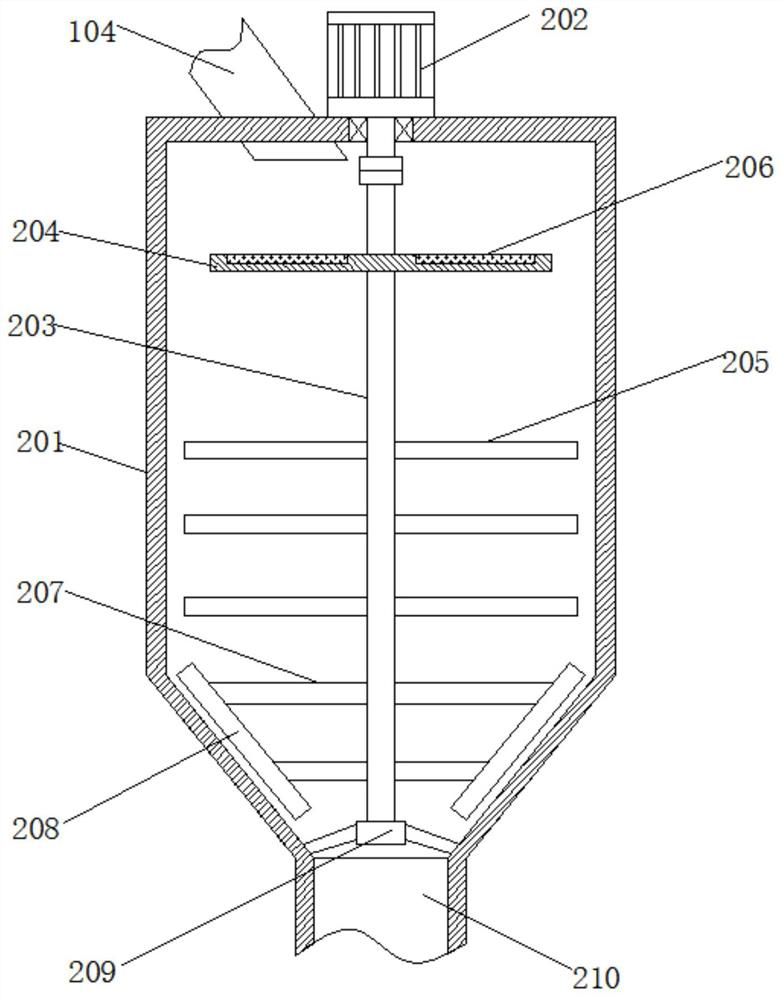

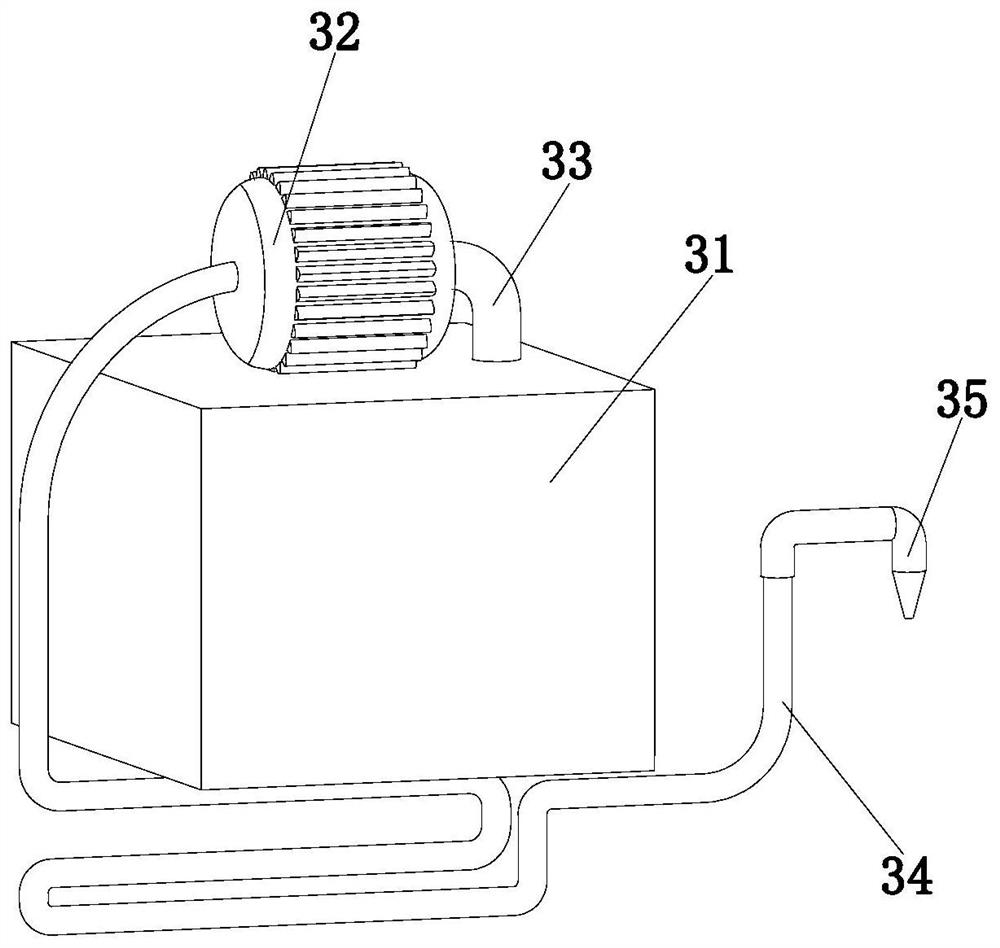

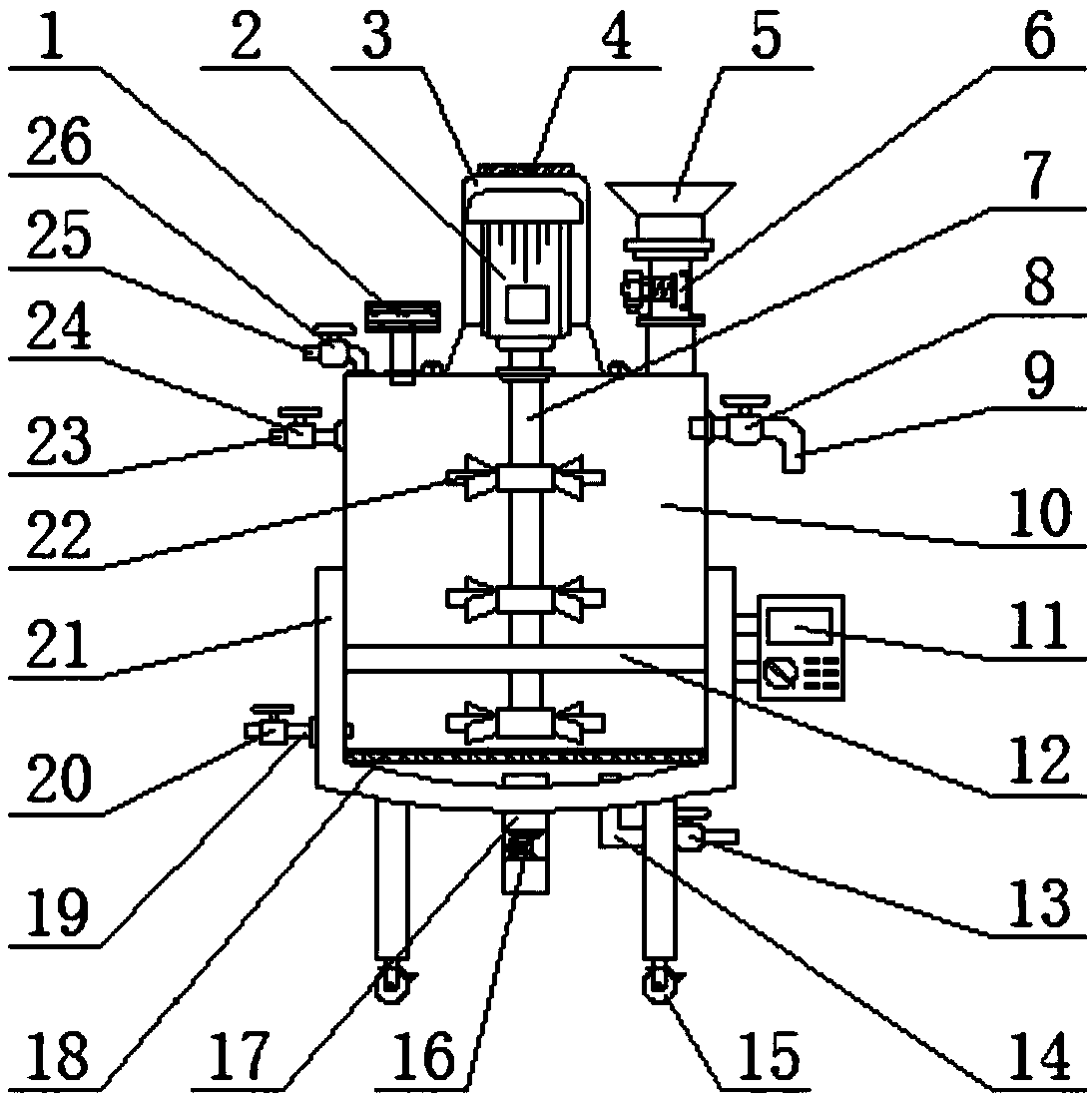

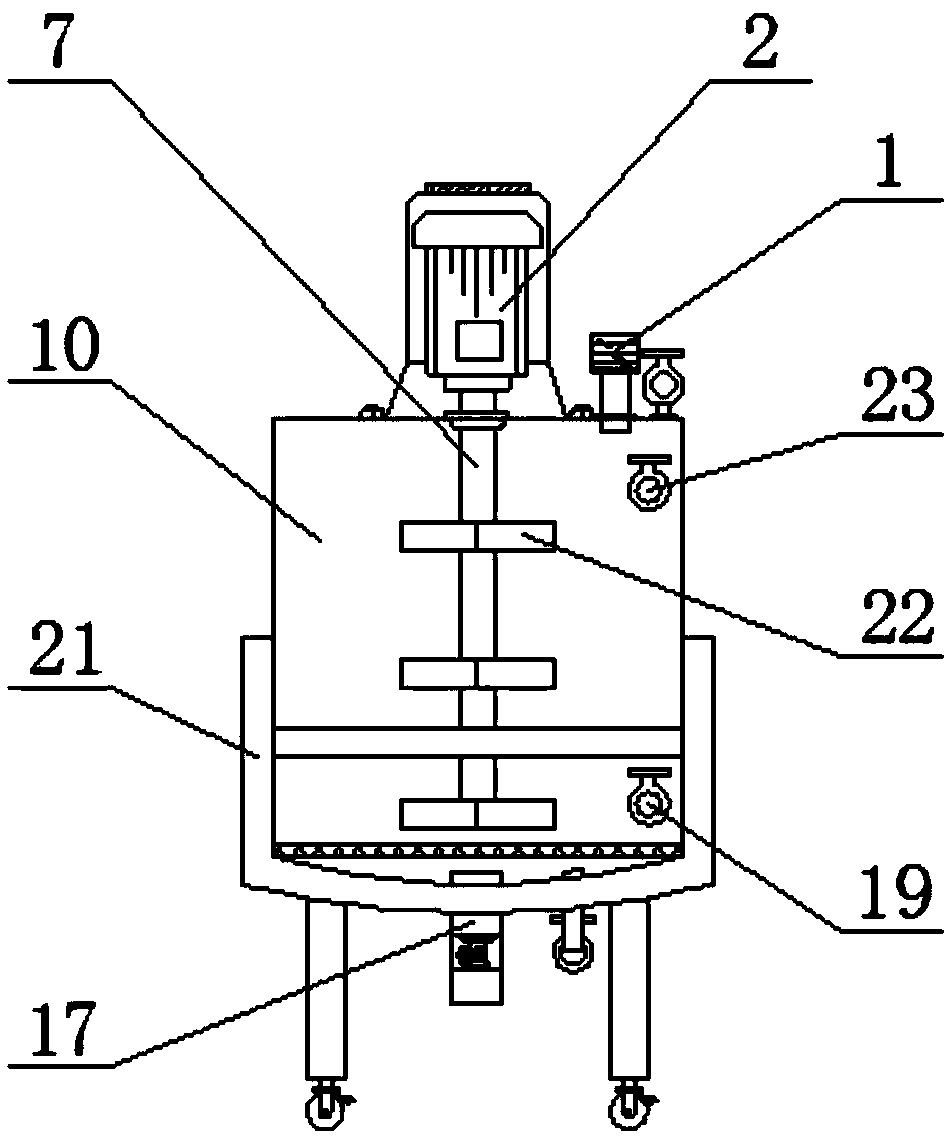

Multifunctional fermentation device for condiments

InactiveCN109321446AEasy to moveImprove applicabilityBioreactor/fermenter combinationsBiological substance pretreatmentsSolenoid valveEngineering

The invention discloses a multifunctional fermentation device for condiments. The multifunctional fermentation device comprises a motor and a support; a fermenting tank is arranged in the inner middleof the support; a discharge outlet is embedded into the inner bottom of the fermenting tank; a discharge outlet solenoid valve is arranged below the discharge outlet; a control panel is arranged on the right side of the support; the motor is mounted in the upper middle of the fermenting tank, and a rotating shaft coated with stirring blades is arranged at a lower end position, close to the motor,in the fermenting tank. The multifunctional fermentation device has the advantages that the solenoid valve is arranged on the feed inlet of a conventional fermentation device, so that automatic feeding can be realized; the feeding quantity can be controlled; and the problem of manual feeding is solved; through a filter screen, impurities can be filtered out during discharge, so that discharged materials are purer, and the sanitary quality of products is improved; through travelling wheels, the fermentation device can be moved, and the mobility and the applicability of the fermentation deviceare improved.

Owner:大连慧航科技发展有限公司

An energy-saving edamame sheller with automatic feeding and conveying

ActiveCN104544507BSolve the problem of manual feedingReduce power consumptionFood treatmentEngineeringConveyor belt

The invention provides an energy-saving green soy bean husking machine capable of conducing automatic feeding and conveying. The energy-saving green soy bean husking machine comprises a feeding device, a conveying device, a husking device, a collecting device, a transmission mechanism assembly and a driving device, wherein the husking device is installed on a machine frame, the conveying device is arranged on one side of the husking device, the collecting device is arranged on the other side of the husking device, the feeding device is arranged at one end of the conveying device, the driving device is arranged at the lower end of the machine frame, and the driving device is connected with and drives the husking device through the transmission mechanism assembly. Automation and high efficiency are achieved, effective effects are achieved, a vibrating screen is replaced with a feeding hopper, and the problem of the manual feeding of an existing green soy bean husking machine is solved; meanwhile, conveying is achieved through a conveyor belt, the problem that the existing green soy bean husking machine is low in husking efficiency is solved, vibration motors are reduced, and the machining and manufacturing cost of the green soy bean husking machine is reduced; in addition, a power mechanism is simplified, energy consumption mechanisms are reduced, the power consumption of the existing green soy bean husking machine is lowered, the collecting device is optimized, and husked green soy beans are cleaner and more sanitary.

Owner:ANHUI AGRICULTURAL UNIVERSITY

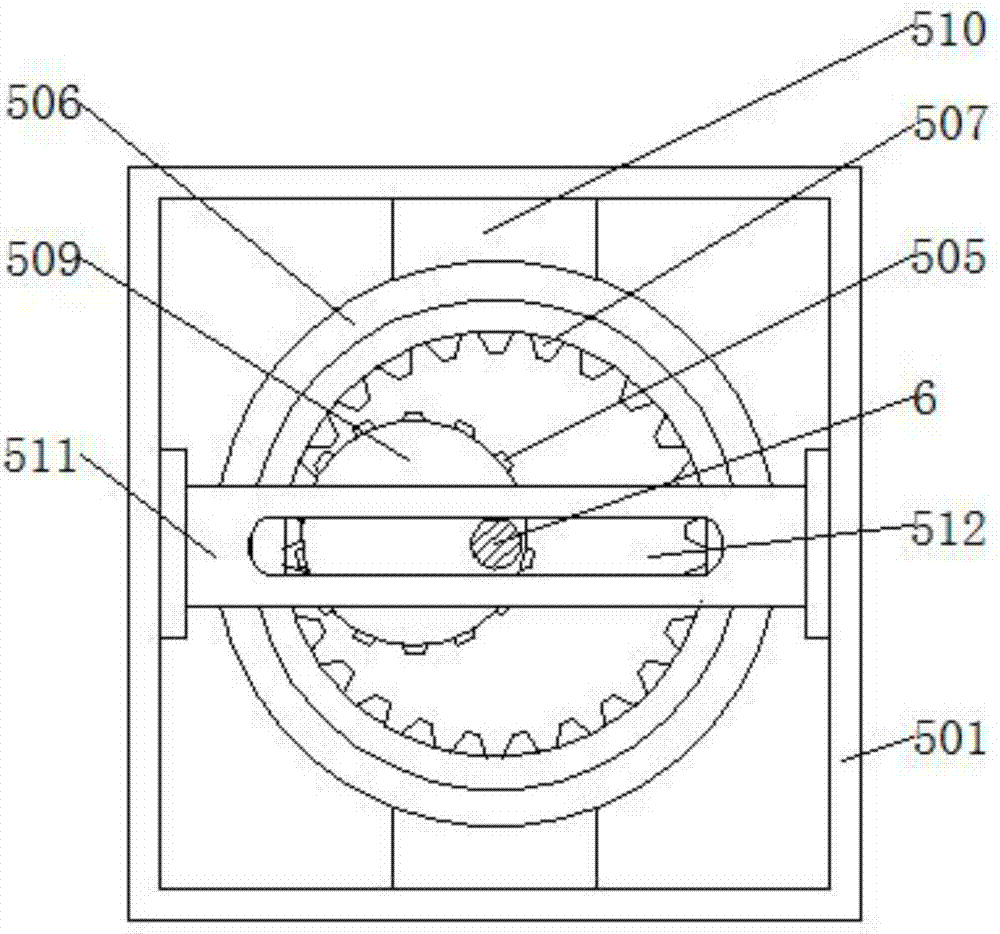

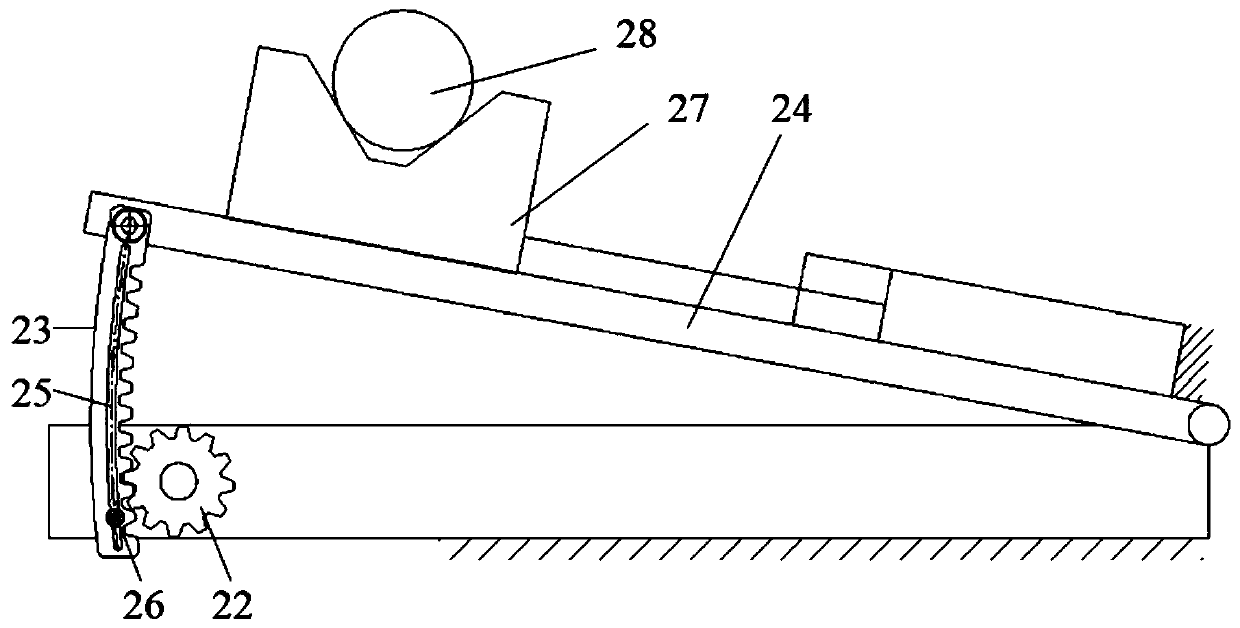

Office table and chair cutting device based on line drive

InactiveCN111844333ASolve the problem of manual feedingReduce labor intensityProfiling/shaping machinesGear wheelEngineering

The invention relates to the technical field of table and chair processing, and discloses an office table and chair cutting device based on line drive. The device comprises a bottom plate, wherein theside surface of the bottom plate is fixedly connected with a reversing block, the bottom surface of the bottom plate is meshed with a first gear, the inner part of the first gear is rotatably connected with a first connecting part, the inner part of the first gear is rotatably connected with an input shaft, the side surface of the bottom plate is rotatably connected with a first rotating wheel, the outer side of the first rotating wheel is connected with a belt in a transmission mode, and the outer side of the belt is connected with a second rotating wheel in a transmission mode. According tothe office table and chair cutting device based on line drive, through the connection of the bottom plate and the second rotating wheel, the problem of manual feeding of an existing cutting device inthe production process of tables and chairs is solved, the labor intensity of workers is effectively reduced, the problem of low safety of the existing cutting device in the production process of thetables and chairs, and in mass production, the cutting effect cannot be affected, plates of different lengths can be flexibly cut, and the cutting efficiency is high.

Owner:广州思威耀家具有限公司

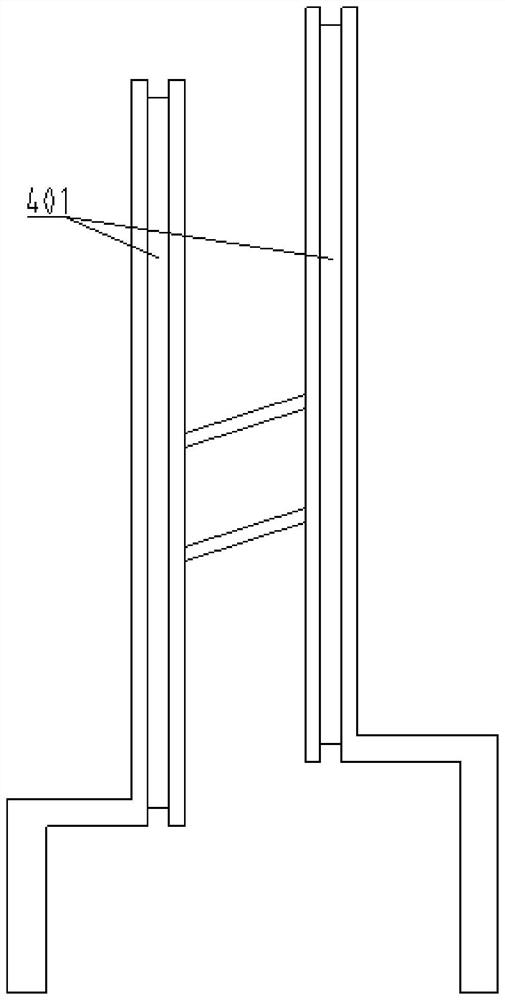

Automatic storing and feeding device

PendingCN114084586ASolve the problem of manual feedingRealize conveying automationConveyorsVertical planeUniversal joint

The invention provides an automatic storing and feeding device. The automatic storing and feeding device comprises a conveying roller, a conveying chain and a transmission gear set. A chain bracket is also included, and the two same conveying chains are arranged in a groove of the chain bracket; the two chains move synchronously, and the conveying roller is fixed to one of the chains through two universal joints respectively; the conveying chains are arranged in parallel in a vertical plane and have a certain vertical height difference; and the conveying roller is connected with the two conveying chains through the two universal joints, the vertical height difference of the two universal joints is the same as the height difference of the two conveying chains so that the conveying roller has a certain inclination angle in the axial direction, and objects stored in the conveying roller can roll out of the roller under the action of gravity. According to the automatic storing and feeding device, the problem that manual feeding is needed during mechanical production of a traditional storing and feeding device is solved, meanwhile, enough raw materials exist, and material conveying automation is achieved.

Owner:CHINA SHIP DEV & DESIGN CENT

Automatic discharging equipment

ActiveCN113120610AReduce labor intensityIncrease productivityConveyor partsMechanical conveyorsEngineeringLeather belt

The invention provides automatic discharging equipment which comprises a rack, an automatic discharging device is arranged on the rack, the automatic discharging device comprises a connection conveying mechanism and a material grabbing conveying mechanism, a material disc conveying mechanism is arranged on one side of the material grabbing conveying mechanism, and a material grabbing mechanism is arranged above the material grabbing conveying mechanism. The connection conveying mechanism is located on one side of the material grabbing conveying mechanism. The material grabbing conveying mechanism comprises an equidistant conveying mechanism and a belt conveying mechanism, the belt conveying mechanism is located between the equidistant conveying mechanism and the connection conveying mechanism, the conveying direction of the equidistant conveying mechanism is perpendicular to the conveying direction of the connection conveying mechanism, and the conveying direction of the belt conveying mechanism is the same as that of the connection conveying mechanism. The equidistant conveying mechanism comprises a plurality of product positions. By the adoption of the technical scheme, connection with a packaging machine is achieved, materials are automatically discharged and loaded into material discs, the production efficiency is greatly improved, the labor cost is saved, and the labor intensity of workers is relieved.

Owner:SHENZHEN IN CUBE AUTOMATION

Die processing material receiving process

InactiveCN103639319BReduce labor intensityTo achieve the purpose of automatic feedingMetal-working feeding devicesPositioning devicesEngineeringUltimate tensile strength

The invention discloses a mould processing collecting technology. According to the technology, an upper mould, a lower mould and a mould of an automatic collector are included. The automatic collector comprises an upper pressing block and two sliding rails. A collecting plate is mounted between the two sliding rails, one end of the collecting plate stretches into the middle of the upper mould and the lower mould, and a support is fixed on the collecting plate. The upper pressing block and the upper mould are moved downwards, so that the upper pressing block presses and pushes the support and drives the collecting plate to be separated from the middle of the upper mould and the lower mould, and the upper mould and the lower mould are closed to press a product. The upper pressing block and the upper mould are moved upwards, so that the pressed product moves upwards along with the upper mould, the upper pressing block is separated and presses a sliding bearing, and the collecting plate enters the middle of the upper mould and the lower mould and is disposed below the pressed product. The pressed product is separated from the upper mould to fall into the collecting plate, so that the product is leaked in a product frame along the collecting plate under the machine tool vibration. By means of the mould processing collecting technology, the worker labor intensity is reduced, and the production efficiency is improved.

Owner:珠海科林模具有限公司

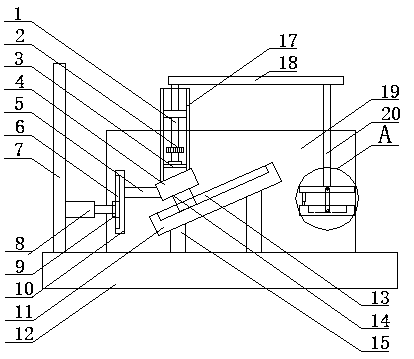

Mold with automatic part catcher

InactiveCN103639320BReduce labor intensityTo achieve the purpose of automatic feedingShaping toolsMetal-working feeding devicesEngineeringMachine tool

The invention discloses a die with an automatic material receiver. The die comprises a machine tool, a machine tool working table and a machine tool sliding block, an upper die and a lower die, wherein the machine tool working table is installed on the machine tool, the machine tool sliding block is located above the machine tool working table and can ascend and descend vertically, the upper die is installed on the machine tool sliding block, and the lower die is installed on the machine tool working table. The die further comprises the automatic material receiver, wherein the automatic material receiver comprises upper pressing blocks fixed on one side of the machine tool sliding block and capable of vertically ascending and descending with the machine tool sliding block and two oblique sliding rails fixed on the side wall of the machine tool and corresponding to the upper pressing blocks. Two material receiving plates capable of sliding along the sliding rails are installed between the sliding rails, one end of each material receiving plate extends into the position between the upper die and the lower die, supports capable of abutting and pushing the upper pressing blocks moving downward so as to drive the material receiving plates to slide along the sliding rails and move away from the position between the upper die and the lower die are fixed on the material receiving plates, and material receiving plate reset springs are further arranged between the sliding rails. By using the die with the automatic material receiver, the labor intensity of workers is reduced, and the production efficiency is improved.

Owner:中山市镇丽塑胶五金制品有限公司

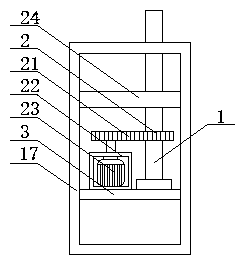

Marking machine

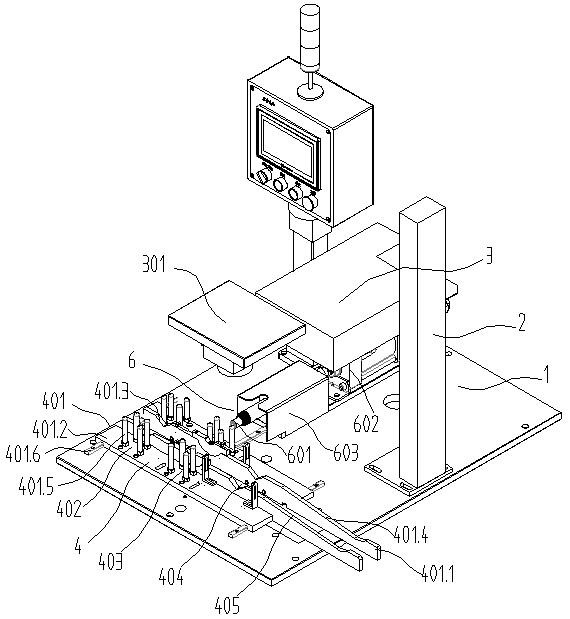

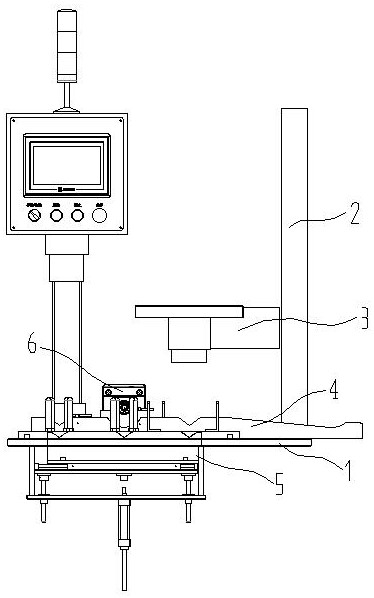

PendingCN111890810ASolve the problem of manual feedingImprove work efficiencyTypewritersOther printing apparatusEngineeringWorkbench

The invention discloses a marking machine which comprises a working table, a support and a marking head. The working table is further provided with a locating device, a conveying device and an adjusting device. The locating device is located on the working table and comprises two locating assemblies which are arranged in parallel. A cavity is formed in the portion, between the two locating assemblies, of the working table. Feeding stations, adjusting stations, marking stations and discharging stations are sequentially arranged on the two locating assemblies from left to right. The conveying device is located below the locating device and comprises a conveying portion. The conveying portion is located in the cavity between the two locating assemblies. The conveying portion is provided withthree taking grooves which correspond to the feeding stations, the adjusting stations and the marking stations. According to the marking machine, the problem of manual feeding of the marking machine is solved, multi-station continuous work is adopted, automatic feeding and discharging are achieved, an operator only needs to place workpieces in a supply area, and the working efficiency is improved.

Owner:日照汇丰电子有限公司

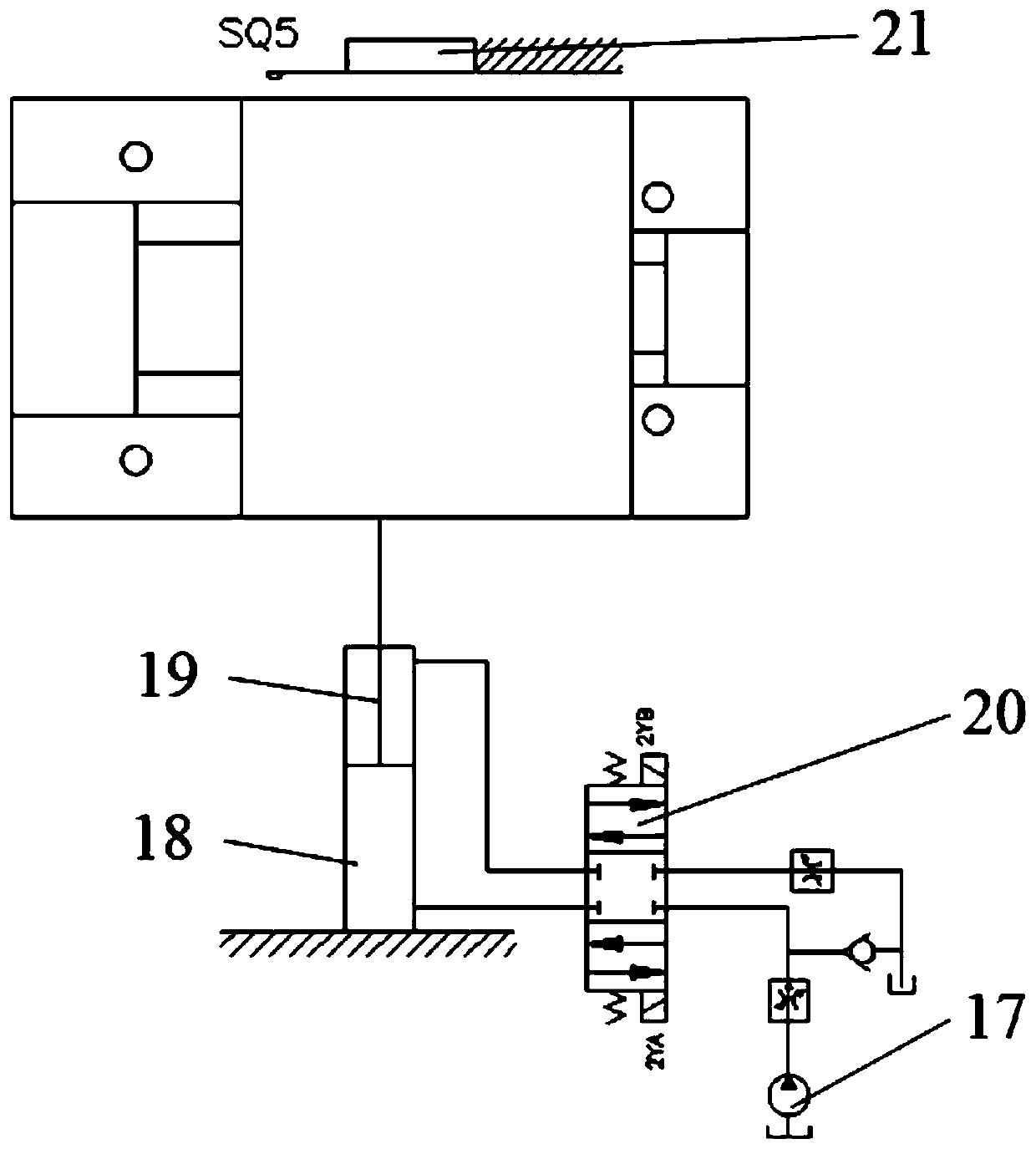

Stirring vat used for bituminous mixing plant

InactiveCN108708256ASolve the problem of manual feedingReduce work intensityRoads maintainenceEngineeringUltimate tensile strength

The invention discloses a stirring vat used for a bituminous mixing plant. The stirring vat comprises a bottom board. A vat body is fixed to the upper end of the bottom board. Two bearing blocks are fixed to the upper end of the bottom board. A fixed block is fixed to the upper ends of the two bearing blocks jointly. Second sliding grooves are formed in the two sides at the upper end of the fixedblock. Second sliding blocks are installed in the second sliding grooves. A push block is fixed to the upper ends of the two second sliding blocks jointly. A casing pipe is fixed to the upper end of the push block. A rotating device is arranged in the casing pipe. A connecting rod is arranged at the upper end of the rotating device. A supporting rod is fixed to the lower end of the connecting rod.A containing device is arranged at the lower end of the supporting rod. A push rod is fixed to one end of the push block. The problem that a material needs to be manually fed in the stirring processis solved through the stirring vat, the material is fed by a worker conveniently, the worker feeds the material more simply, the labor intensity of the worker is reduced, the efficiency in the workingprocess is improved, and use is convenient.

Owner:亚建科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com