Energy-saving environment-friendly type smelting furnace

A technology for energy saving and environmental protection, melting furnace, applied in furnaces, crucible furnaces, furnace types and other directions, can solve the problems of poor environmental protection performance, low lead content in slag, low safety of melting furnaces, etc., to improve occupational hygiene conditions, protect Environment, the effect of solving heat dissipation and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

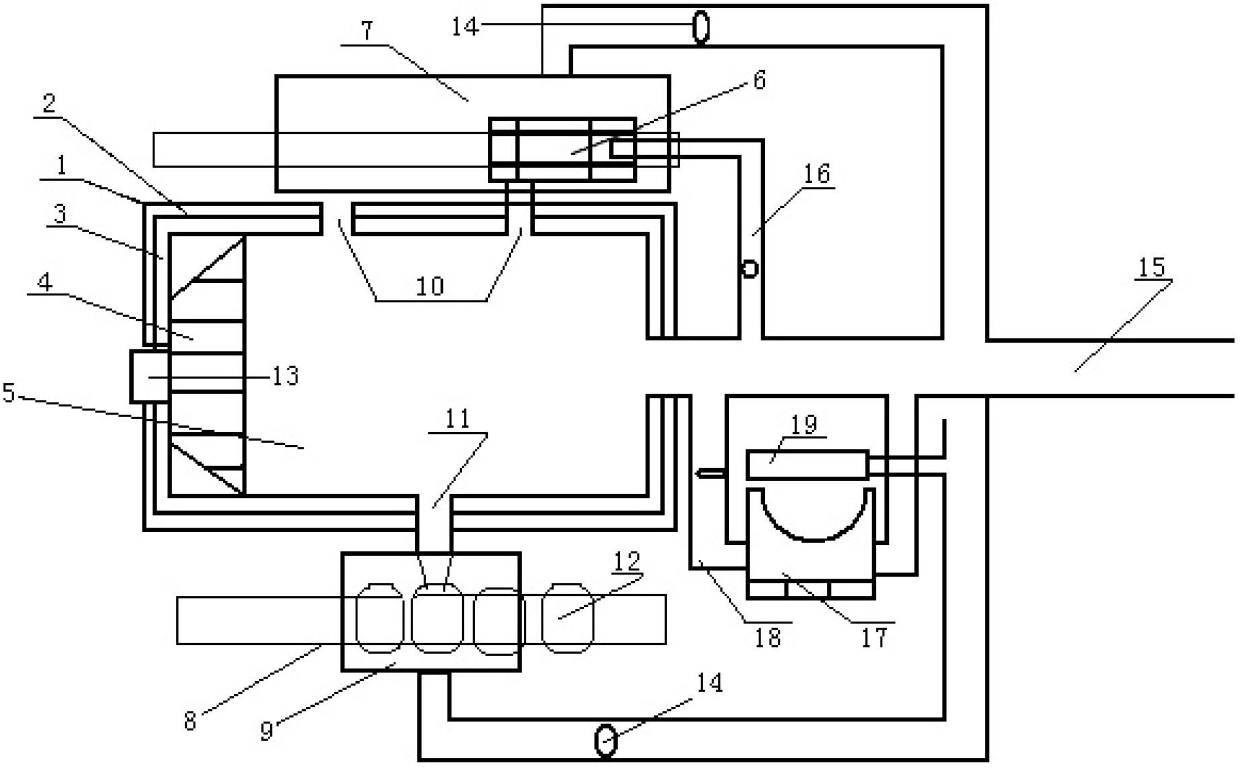

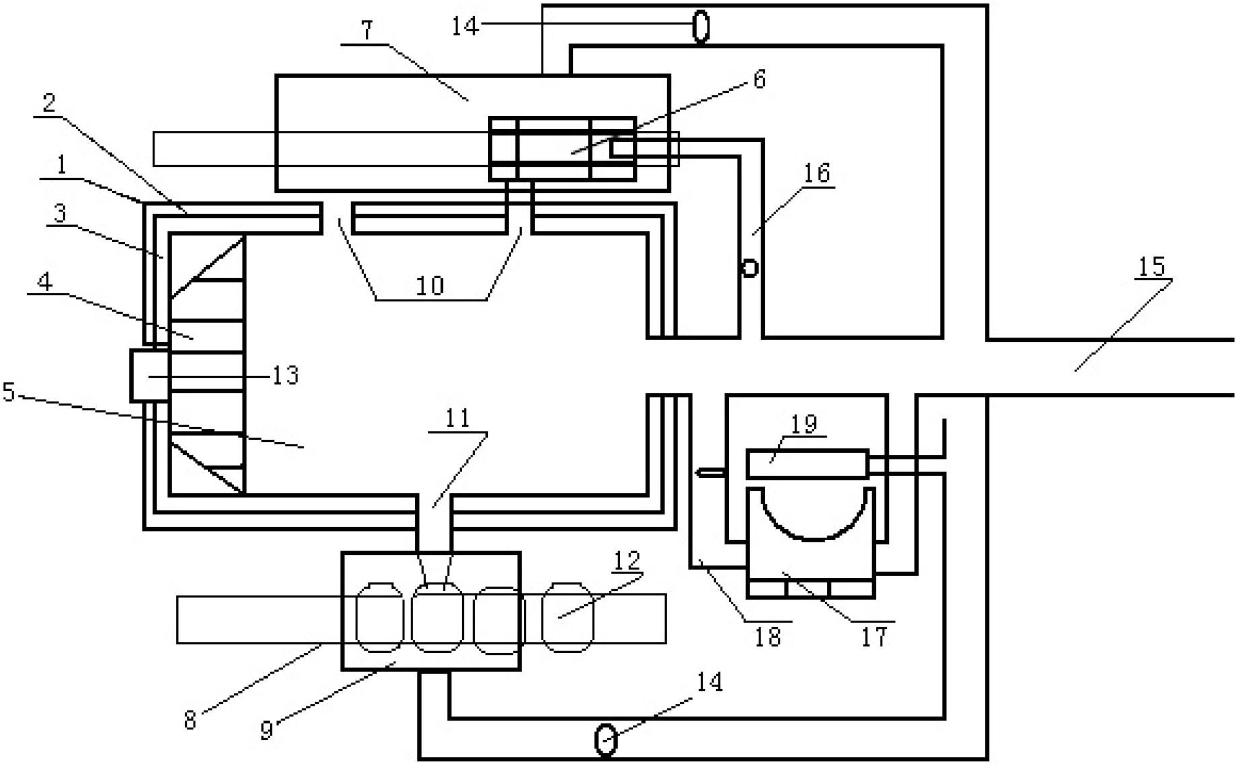

[0043] The smelting furnace of the embodiment of the present invention mainly includes: thermal insulation wall 1, thermal insulation layer 2, wall 3, combustion chamber 4, melting chamber 5, feeding bin 6, upper dedusting chamber 7, feeding track 8, lower dedusting chamber 9, Feeding port 10, discharge port 11, discharge pot 12, combustion chamber inspection port 13, dust removal switch 14, waste gas collection pipe 15, waste gas waste heat recovery secondary pipe 16, lead melting pot 17, waste gas waste heat recovery large pipe 18, Lead melting pot dust removal chamber 19 and feeding bin rail 20 and other components; mainly divided into heating and melting system, feeding system, discharging system, exhaust gas and dust collection system;

[0044] Wherein the heating melting system comprises a support, a combustion chamber 4, a melting chamber 5 and a lead melting pot, the combustion chamber 4 is arranged on one side of the melting chamber 5, the combustion chamber 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com