Automatic discharging equipment

An automatic unloading and equipment technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of affecting production efficiency, high work intensity, low production efficiency, etc., to avoid manual feeding and leakage, reduce The labor intensity of workers and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

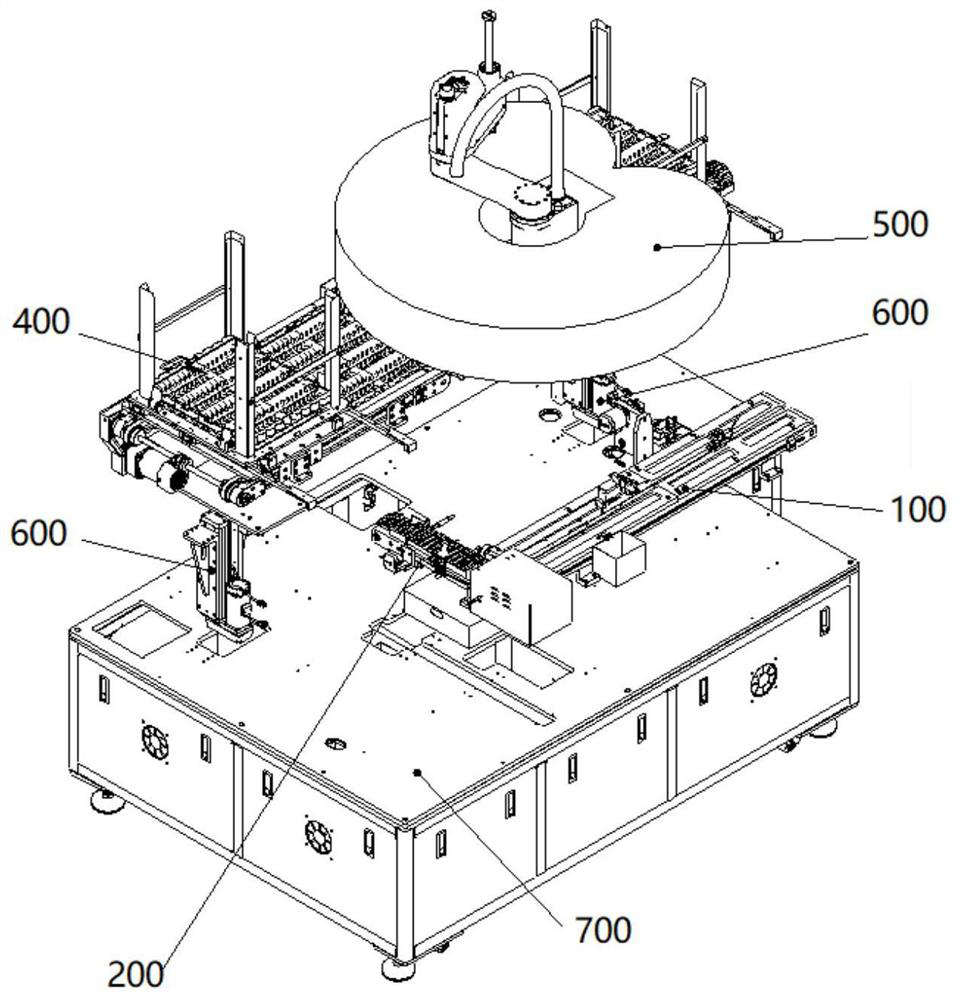

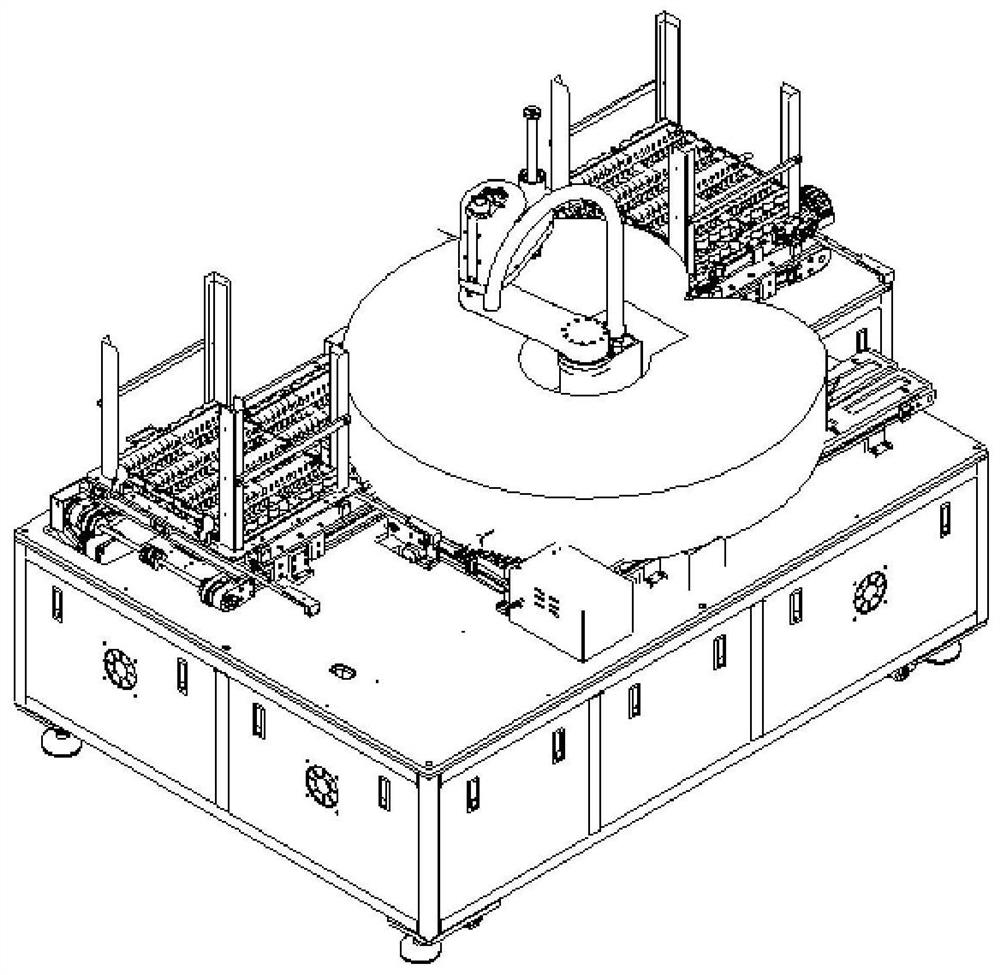

[0064] Such as Figure 1~Figure 3 As shown, a kind of automatic unloading equipment, it comprises frame 700, and described frame 700 is provided with automatic unloading device, and described automatic unloading comprises connecting conveying mechanism 100 and grasping material conveying mechanism, and described grasping material One side of the conveying mechanism is provided with a tray conveying mechanism 400, and above the grasping conveying mechanism is provided with a grasping mechanism 500; both ends of the conveying mechanism 400 are provided with a tray jacking mechanism for loading and unloading the tray 600;

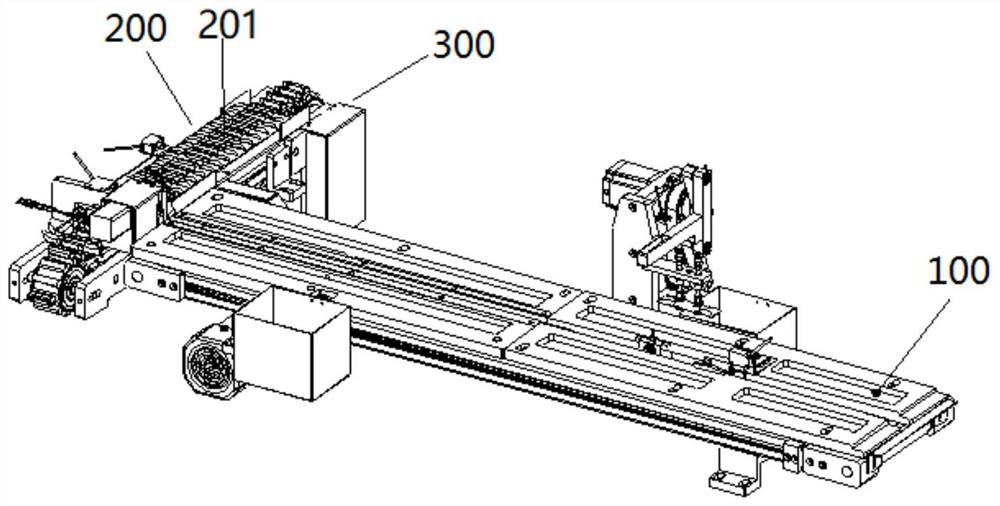

[0065] The connecting conveying mechanism 100 is located on one side of the grasping conveying mechanism; the grasping conveying mechanism comprises an equidistant conveying mechanism 200 and a belt conveying mechanism 300, and the belt conveying mechanism 300 is located between the equidistant conveying mechanism 200 and the connecting conveying mechanism. B...

Embodiment 2

[0068] Such as Figure 4 and Figure 5 As shown, the tray transfer mechanism 400 includes a full tray conveyor belt 401 and an empty tray conveyor belt 402 connected to each other. One side of the full tray conveyor belt 401 is provided with a full tray palletizing mechanism 403, and the empty tray conveyer belt One side of the belt 402 is provided with an empty tray separating mechanism 404, and the trays will be divided into individual trays by the empty tray dividing mechanism 403 and placed on the empty tray conveyor belt 401. When the tray is full, the products will be sent through the full tray conveyor belt 402. To the full tray stacking mechanism 404 stacked together. Wherein, the empty tray separating mechanism 403 and the full tray stacking mechanism 404 adopt structures of the prior art.

Embodiment 3

[0070] Such as image 3 , Figure 6~Figure 11 As shown, an automatic docking and unloading equipment includes a docking conveying mechanism 100 and a grabbing conveying mechanism, and the docking conveying mechanism 100 is located on one side of the grabbing conveying mechanism; the grabbing conveying mechanism includes an equidistant conveying mechanism 200 and a belt conveying mechanism 300, the belt conveying mechanism 300 is located between the equidistant conveying mechanism 200 and the docking conveying mechanism 100, the conveying direction of the equidistant conveying mechanism 200 is perpendicular to the conveying direction of the docking conveying mechanism 100, and the belt The conveying direction of the conveying mechanism 300 is the same as that of the docking conveying mechanism 100; the equidistant conveying mechanism 200 includes several product positions 201; the docking conveying mechanism 100 conveys products to one side of the belt conveying mechanism 300, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com