Mold with automatic part catcher

A feeder, automatic technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency and high labor intensity of workers, so as to improve production efficiency, reduce labor intensity, and solve the problem of manual feeding. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

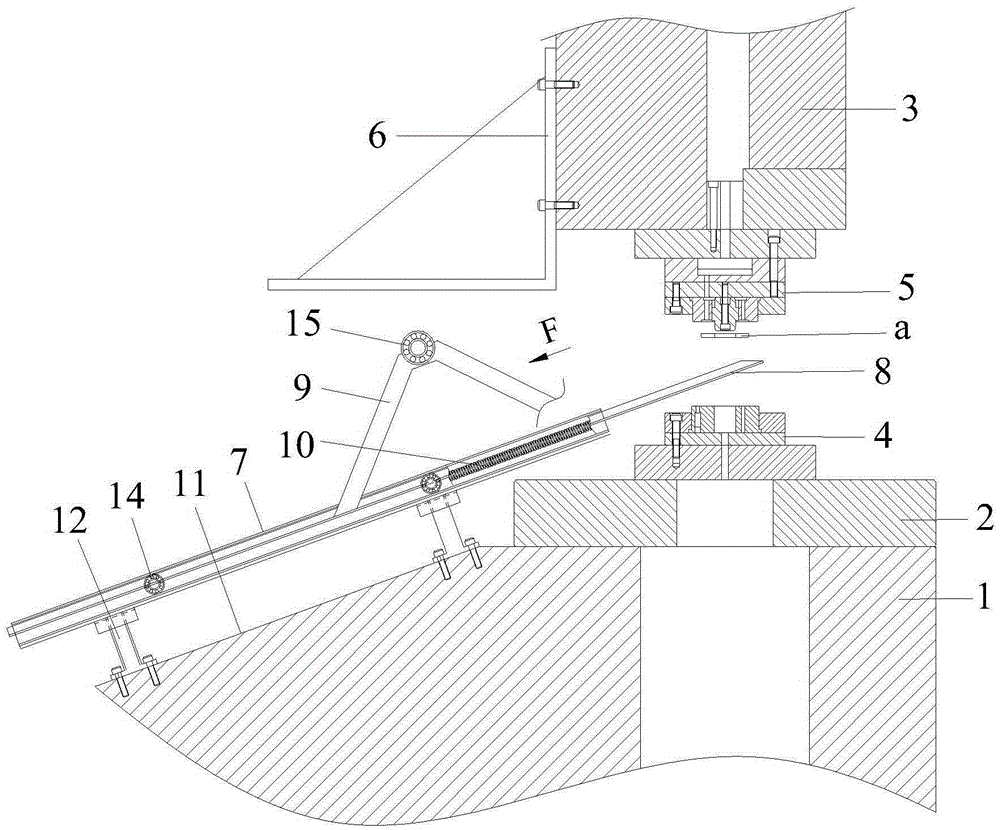

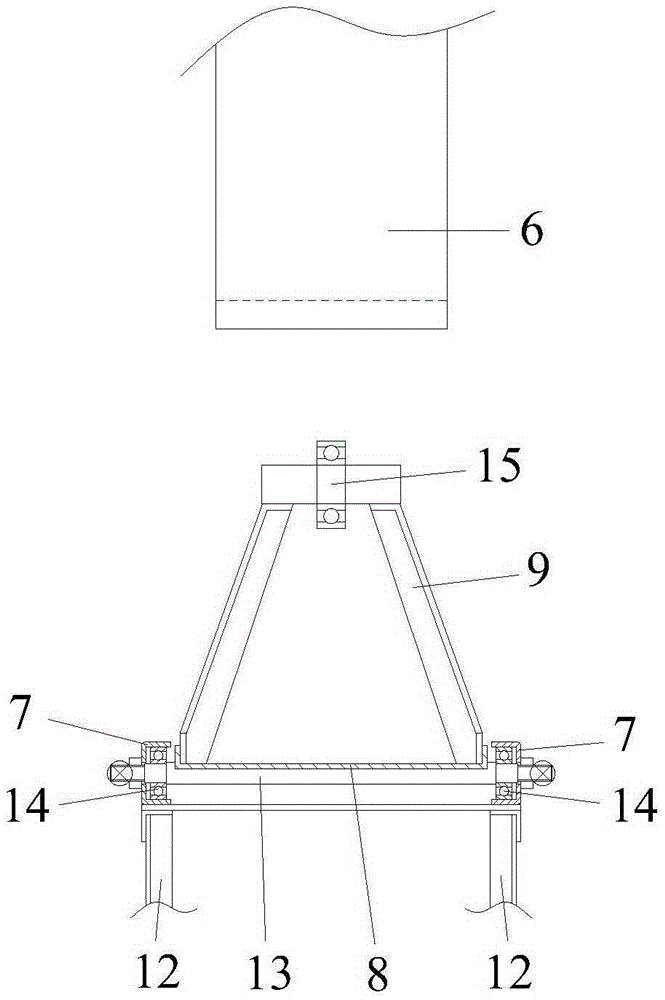

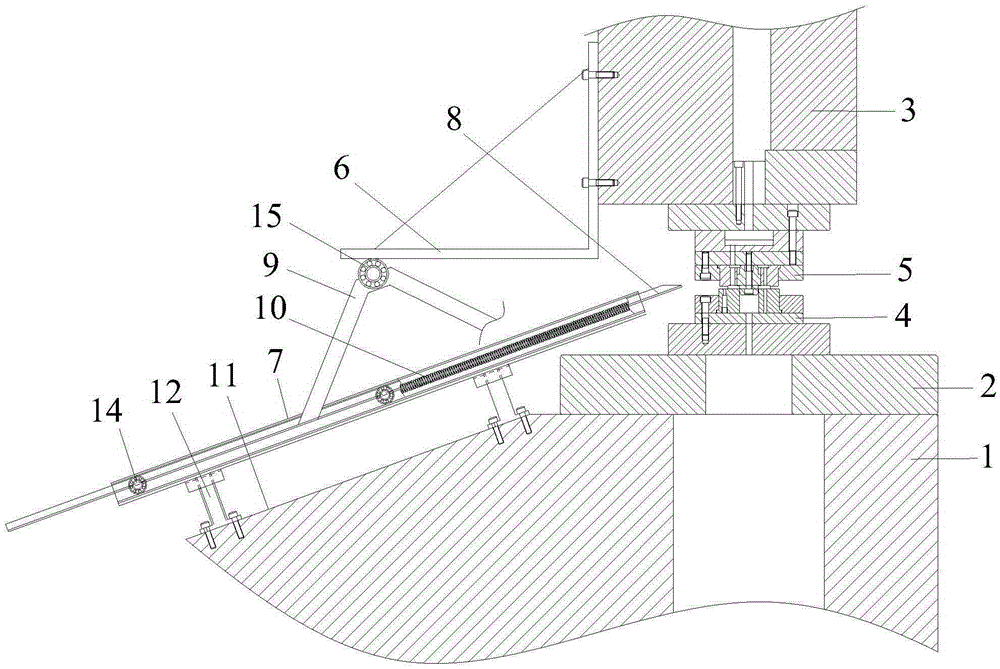

[0014] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0015] Please refer to Figure 1-3 , The mold with automatic material catcher of the present invention comprises machine tool 1, machine tool table 2, machine tool slide block 3, lower mold 4 and upper mold 5 and automatic material catcher.

[0016] The machine tool table 2 is installed on the machine tool 1, the machine tool slider 3 is located above the machine tool table 2 and can be lifted up and down, the lower mold 4 is installed on the machine tool table 2, and the The upper mold 5 is installed on the machine tool slider 3 and can be matched with the lower mold 4. The automatic material receiver includes a tool that is fixed on one side of the machine tool slider 3 and can go up and down with the machine tool slider 3. The lifting upper pressing block 6, and two inclined slide rails 7 corresponding to the upper pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com