Full-automatic numerical control batten cutting saw, production line and method

A fully automatic cutting saw technology, which is applied in the direction of sawing machine, metal sawing equipment, sawing machine accessories, etc., can solve the problems of low work efficiency, high labor intensity, and high manual participation, so as to reduce work efficiency and improve work efficiency. Efficiency, the effect of increasing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

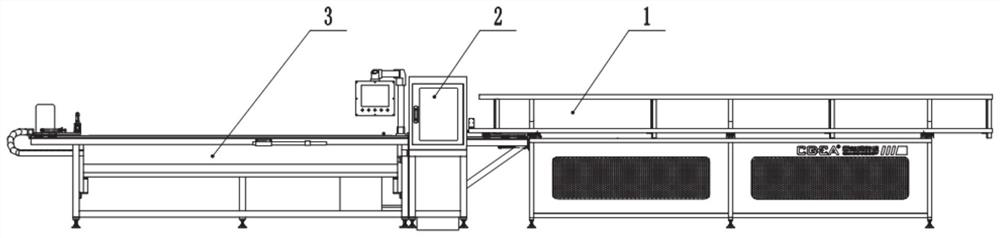

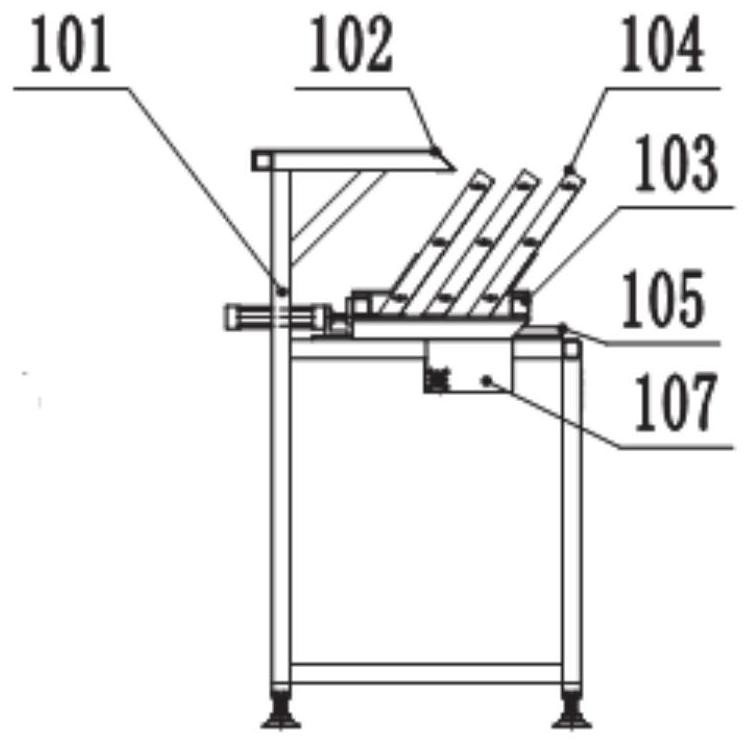

[0038] Such as Figure 1-Figure 5 As shown, a fully automatic numerical control bead cutting saw is characterized in that it includes: a main machine frame, and a working mechanism, a positioning mechanism and a feeding mechanism installed on the top of the main frame from left to right; the feeding mechanism It includes a transmission mechanism and a feeding plate, one end of the feeding plate is installed with a limit piece, the other end is connected with the transmission mechanism, and the feeding plate is slidably connected with the main frame. After the limit piece limits the bead, the transmission mechanism drives the feeding plate to transport it to the positioning mechanism. After the bead is positioned by the positioning mechanism, the bead is cut by the working mechanism.

[0039] The feeding mechanism includes a feeding slider, the feeding plate is connected with the feeding guide rail through the feeding slider, and the feeding guide rail is connected with the hos...

Embodiment 2

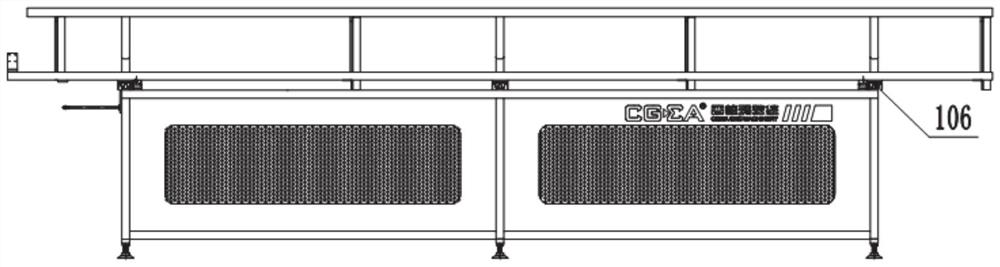

[0053] Such as figure 1 As shown, the present disclosure provides a fully automatic CNC bead cutting production line, including: a silo part, a material pumping part and a fully automatic CNC bead cutting saw as described in the above embodiments;

[0054] The silo part includes a silo frame, the silo frame is provided with a mounting plate, and the mounting plate is slidably connected with the moving silo; the other side of the mounting plate is connected with the silo feeding cylinder through the silo connecting plate; The floating joint connection of the feeding mechanism is used to drive the movement of the feeding mechanism of the fully automatic CNC bead cutting saw;

[0055] Further, the mobile silo includes a moving plate and several adjustable baffles, and the mobile silo is divided into several sub-bins through several adjustable baffles; the adjustable baffle is slidably connected with the moving plate, and can be adjusted by longitudinal movement The size of the m...

Embodiment 3

[0065] A fully automatic CNC bead cutting production line, including: a silo part, a main machine part, a material pumping part, and a measuring part;

[0066] The silo part includes: silo frame, stainless steel plate, mobile silo, adjustable baffle, guide rail, slider, silo connecting plate, slider installed on the mobile silo and silo frame. The guide rails are installed together, and the mobile silo moves longitudinally to select the profile to be processed, and the number of silos can be increased as needed. The adjustable baffle is installed on the moving silo, and is used to place the profiles to be processed in an inclined shape. The adjustable baffle can move longitudinally to adjust the size of the silo, and is suitable for the placement of various profiles. A stainless steel plate is installed on the top of the silo frame, and the profile storage area. The silo connecting plate is installed on the silo frame, the feeding cylinder is installed on the silo connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com