Full-automatic edge banding equipment and method for section of sheet material

An edge banding equipment, fully automatic technology, applied in metal processing equipment, grinding/polishing equipment, wood processing equipment and other directions, can solve the problems of heavy equipment, high cost, reduce practical reliability, etc., to save manpower and material resources, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

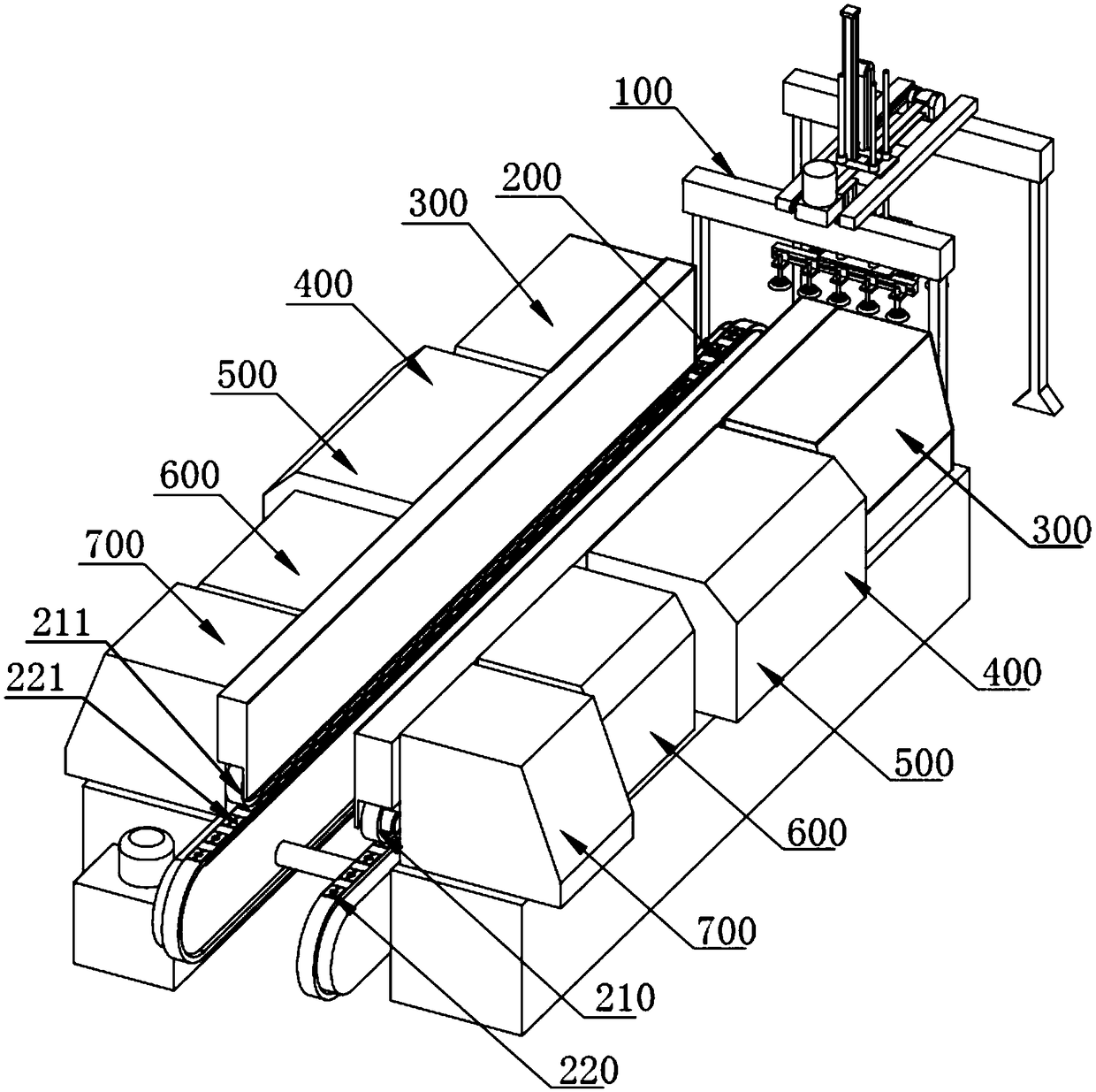

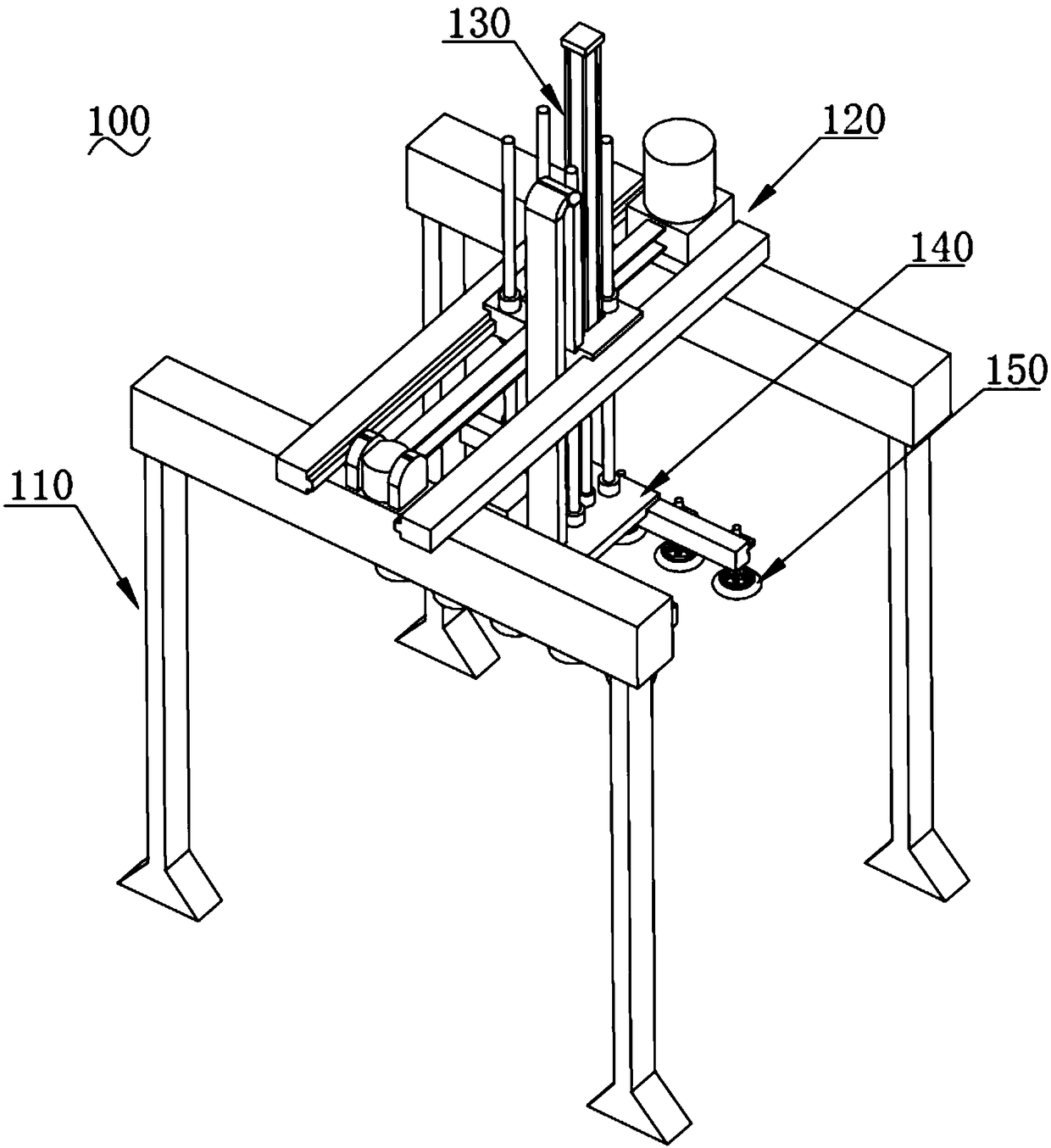

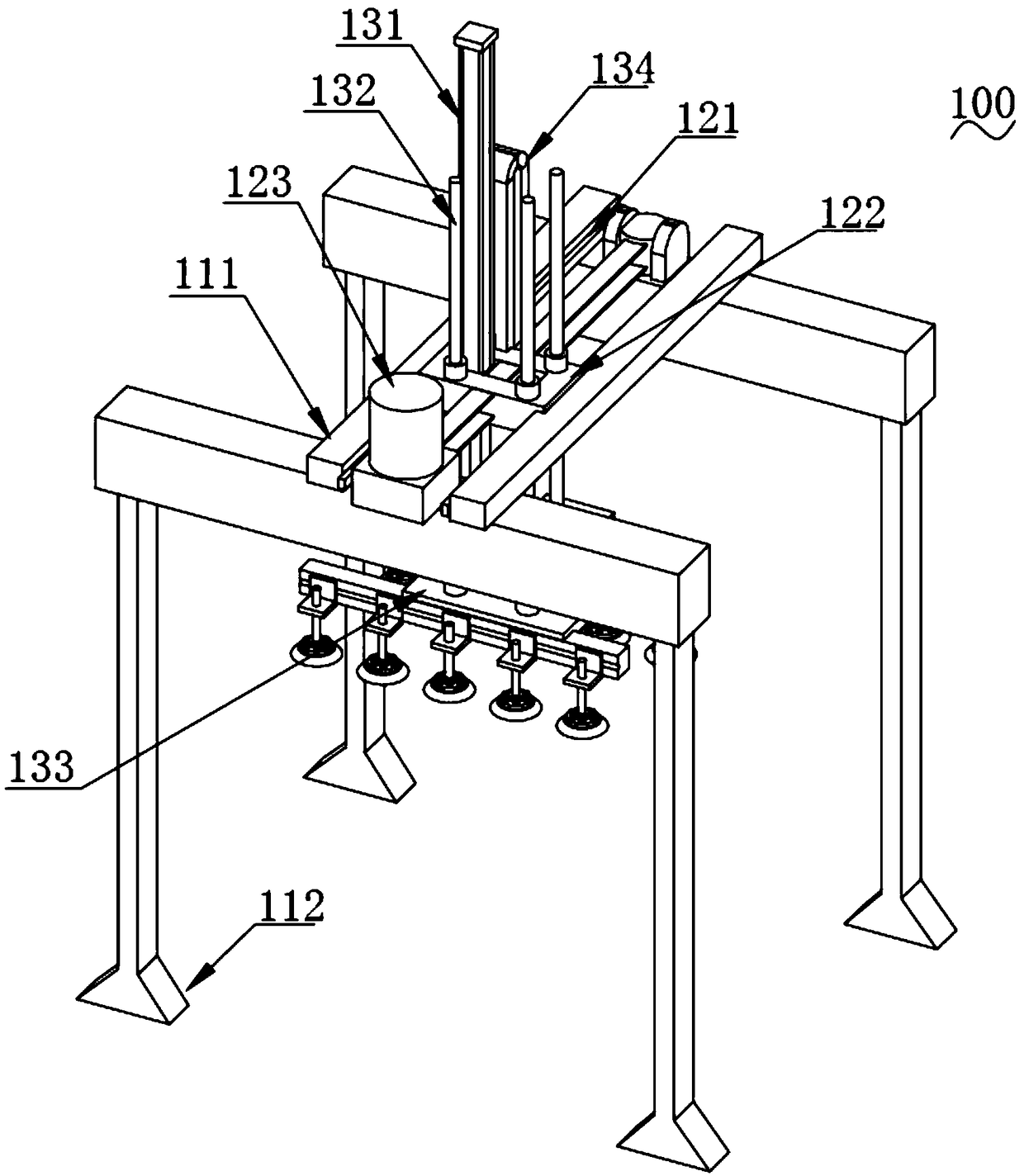

[0050] Such as figure 1 As shown, a fully automatic cutting edge banding equipment 10 for plates includes a feeding device 100 for grabbing and feeding the plates, a conveying device 200 for grabbing and transporting the plates by the feeding device 100, and a device for cutting the plates during the conveying process. The surface cutting device 300, the edge banding device 400 for sealing the edge of the plate after cutting the surface, the trimming device 500 for trimming the edge of the plate, the polishing device 600 for polishing the trimmed plate, and the beating device for sanding the polished plate The sanding device 700 , the surface cutting device 300 , the edge sealing device 400 , the trimming device 500 , the polishing device 600 and the sanding device 700 are sequentially arranged on the conveying device 200 , and the feeding device 100 is located on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com