High-efficiency intelligent bottle cap mounting mechanical arm and working method thereof

A technology of mechanical arm and bottle cap, which is applied in the safety/control of bottle capping machine, bottle/container cap, packaging, etc. It can solve the problems that affect the development of enterprises, the installation of bottle caps is not good, and the shelf life of items in the bottle is shortened. , to improve the quality and efficiency of installation, shorten the time for grabbing bottle caps, and save equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

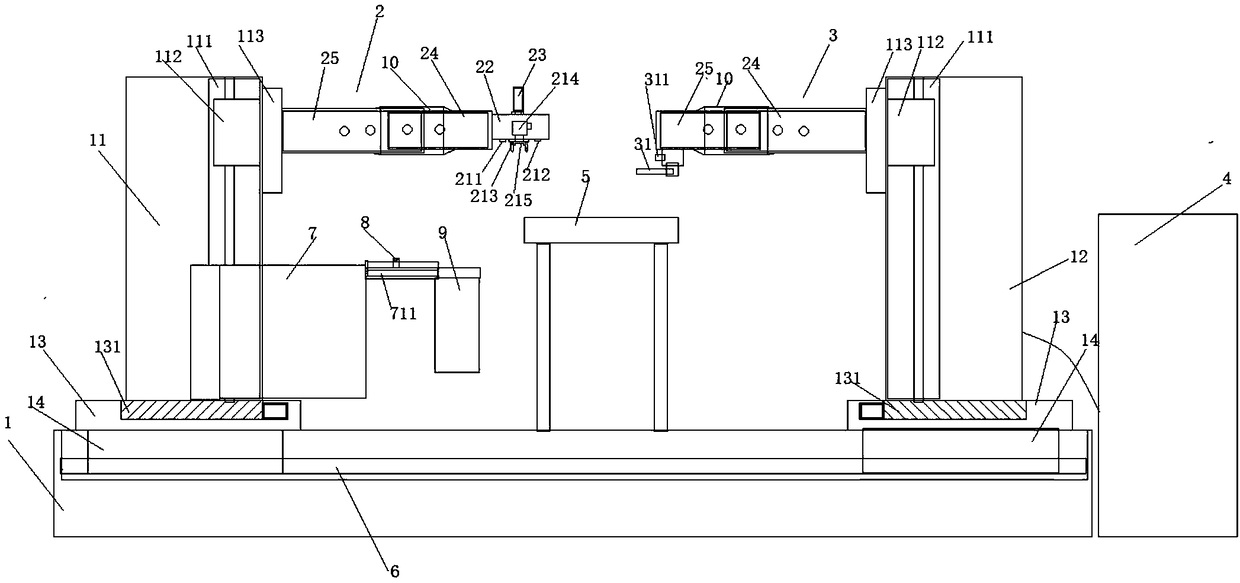

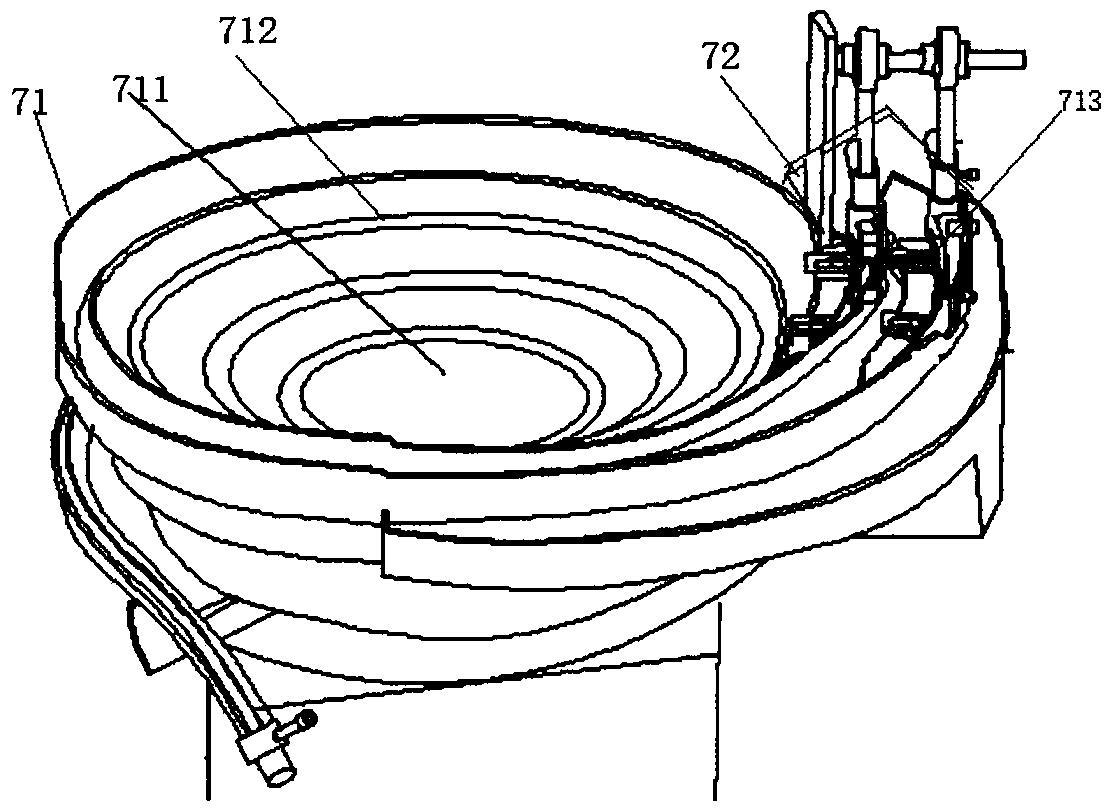

[0106] The high-efficiency and intelligent bottle cap installation robot arm includes: a base 1, a first robot arm 2 for grabbing a bottle cap, a second robot arm 3 for fixing a bottle body, and a control device 4. The base 1 is provided with a first column 11 and a second column 12, and a workbench 5 is arranged between the first column 11 and the second column 12;

[0107]The first mechanical arm 2 and the second mechanical arm 3 are installed on the first column 11 and the second column 12 respectively, the base 1 is provided with a track 6, and the first column 11 and the second column 12 are opposite located at both ends of the track 6;

[0108] And the first column 11 and the second column 12 below are provided with a fixed seat 13, the fixed seat 13 below is provided with a slide block 14, the slide block 14 is located in the track 6, and the slide block 14 and Slider drive mechanism connection;

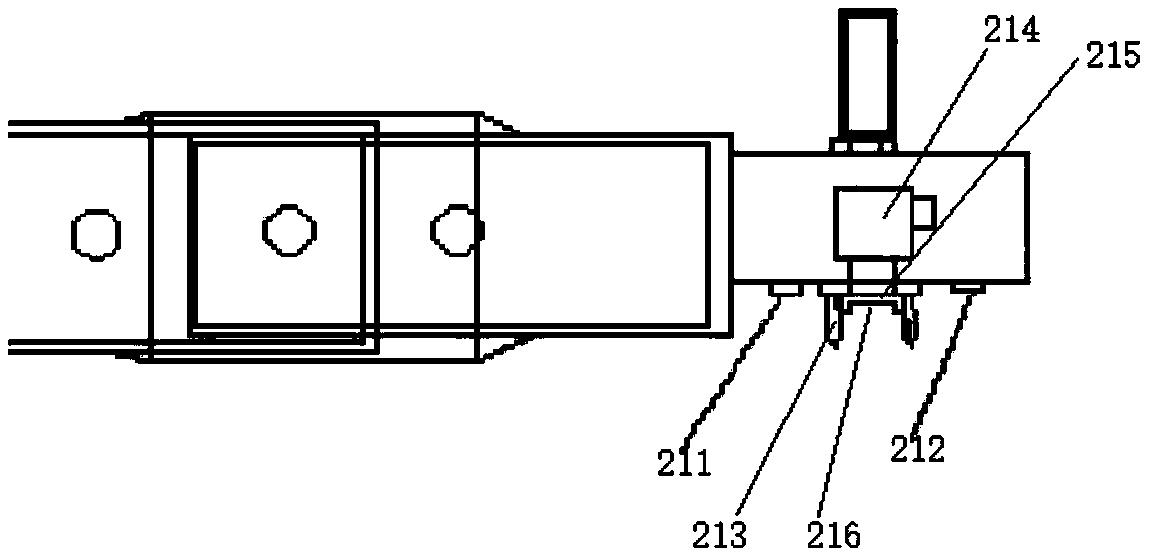

[0109] The end of the first mechanical arm 2 is provided with a capping...

Embodiment 2

[0113] The high-efficiency and intelligent bottle cap installation robot arm includes: a base 1, a first robot arm 2 for grabbing a bottle cap, a second robot arm 3 for fixing a bottle body, and a control device 4. The base 1 is provided with a first column 11 and a second column 12, and a workbench 5 is arranged between the first column 11 and the second column 12;

[0114] The first mechanical arm 2 and the second mechanical arm 3 are installed on the first column 11 and the second column 12 respectively, the base 1 is provided with a track 6, and the first column 11 and the second column 12 are opposite located at both ends of the track 6;

[0115] And the first column 11 and the second column 12 below are provided with a fixed seat 13, the fixed seat 13 below is provided with a slide block 14, the slide block 14 is located in the track 6, and the slide block 14 and Slider drive mechanism connection;

[0116] The end of the first mechanical arm 2 is provided with a cappin...

Embodiment 3

[0121] The high-efficiency and intelligent bottle cap installation robot arm includes: a base 1, a first robot arm 2 for grabbing a bottle cap, a second robot arm 3 for fixing a bottle body, and a control device 4. The base 1 is provided with a first column 11 and a second column 12, and a workbench 5 is arranged between the first column 11 and the second column 12;

[0122] The first mechanical arm 2 and the second mechanical arm 3 are installed on the first column 11 and the second column 12 respectively, the base 1 is provided with a track 6, and the first column 11 and the second column 12 are opposite located at both ends of the track 6;

[0123] And the first column 11 and the second column 12 below are provided with a fixed seat 13, the fixed seat 13 below is provided with a slide block 14, the slide block 14 is located in the track 6, and the slide block 14 and Slider drive mechanism connection;

[0124] The end of the first mechanical arm 2 is provided with a cappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com