Aluminum alloy tubing straightening method and special fixture thereof

A special fixture and aluminum alloy technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of not being able to ensure that aluminum alloy pipes will not be flattened, and achieve the effect of ensuring straightening quality and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The outer diameter of the aluminum alloy pipe is 20mm, the wall thickness is 1.6mm, and the length is 2000mm. After heat treatment, the deflection of the aluminum alloy pipe is 2.0mm / m, and the yield strength is 290kg / cm 2 .

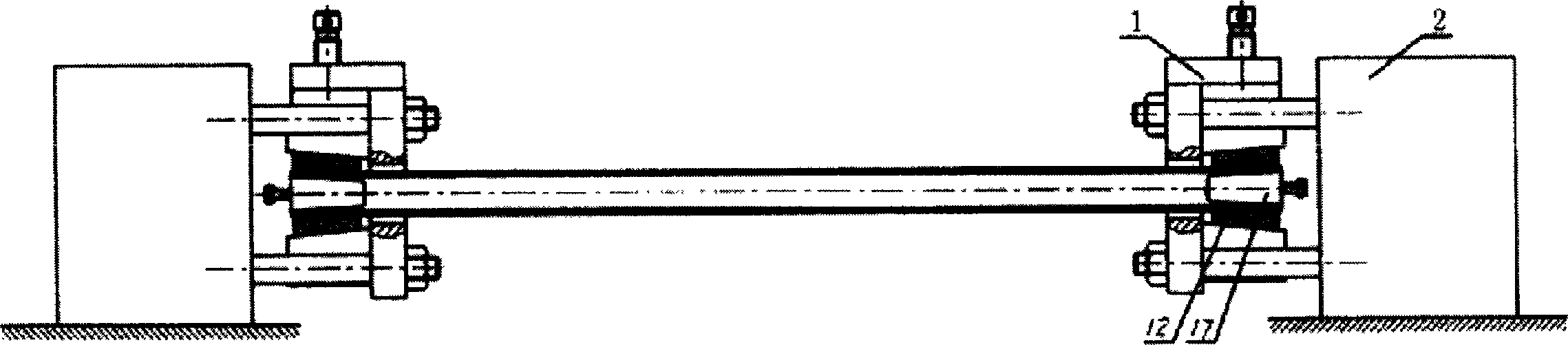

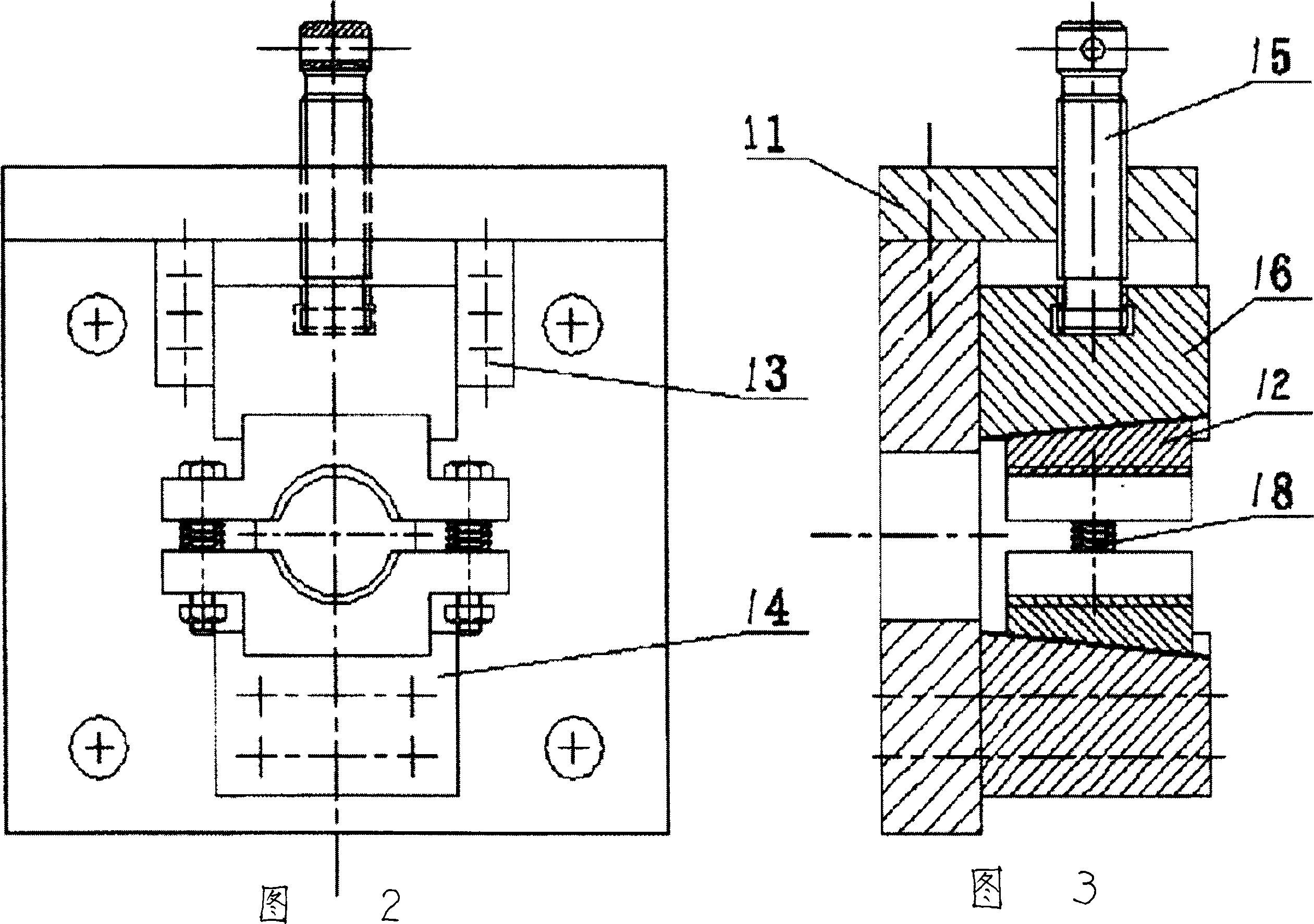

[0017] Be contained on the drawing machine 2 with the special clamp 1 that the present invention provides, as figure 1 As shown, the special clamp (as shown in Figures 2 and 3) is made up of frame 11, jaw teeth 12, guide plate 13, fixed briquetting block 14, screw rod 15, movable briquetting block 16, plug head 17 and spring assembly 18. The fixed briquetting block 14 is directly fixed on the frame 11, and the movable briquetting block 16 is mounted on the frame 11 by a screw rod 15. The position of the movable briquetting block is opposite to the fixed briquetting block 14, and the frame 11 is also fixed with a guide plate 13, which not only limits the movable briquetting block 16 rotates and guides the moving direction of the movable briquetti...

Embodiment 2

[0022] The outer diameter of the aluminum alloy pipe is 50mm, the wall thickness is 2.5mm, and the length is 7000mm. The deflection of the aluminum alloy pipe after heat treatment is 0.2mm / m, and the yield strength is 290kg / cm 2 . Installation and drawing method on drawing machine 2 are the same as embodiment 1. The drawing set was 2.0%. The deflection after drawing is 0.12~0.08mm / m, and the yield strength is 396kg / cm 2 , tensile strength up to 506kg / cm 2 .

Embodiment 3

[0024] The outer diameter of the aluminum alloy pipe is 25mm, the wall thickness is 1.8mm, and the length is 3000mm. The deflection of the aluminum alloy pipe after heat treatment is 0.5mm / m, and the yield strength is 290kg / cm 2 . Installation and drawing method on drawing machine 2 are the same as embodiment 1. The drawing set was 1.0%. After drawing, the deflection is 0.22~0.15mm / m, and the yield strength is 358kg / cm 2 , tensile strength up to 491kg / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com